How to Read an Arc Flash Label

by Jason Mazzola on Oct 19, 2021 10:39:00 AM

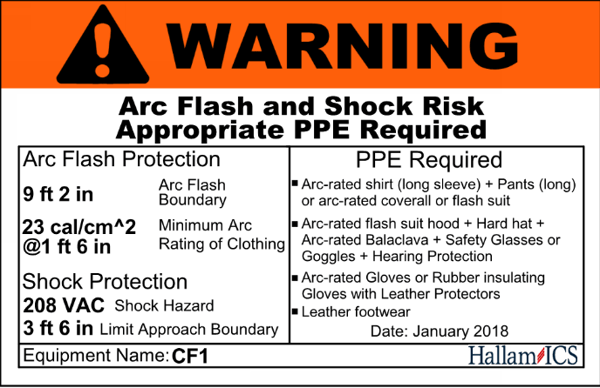

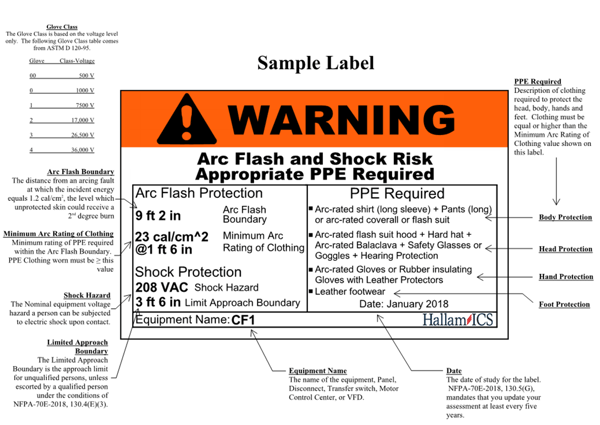

Having your equipment labeled is a critical step in protecting your workers from the hazards of electrical shock and arc flash. Making sure that you and your employees understand the label will ensure that safe work practices are adhered to and workers are properly protected. Below I will go through the label piece by piece to give you an easy to understand overview of the information being presented.

WARNING:

This section is hopefully self-explanatory. It’s just letting you know that there is a hazard present and what the hazard is; in this case “Arc Flash and Shock Risk”.

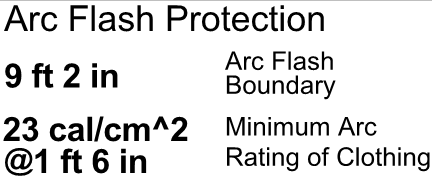

Arc Flash Protection:

This section is broken into two parts, Arc Flash Boundary and Minimum Arc Rating of Clothing. The Arc Flash Boundary is the distance that unprotected skin could receive a second degree burn and is the distance that you would set up your work zone barricades if greater than the 42-inch limited approach boundary defined in NFPA 70E. The Minimum Arc Rating of Clothing is telling you that at a working distance of 1 foot 6 inches (this is the assumed working distance when doing the calculations), what the minimum clothing requirement is to ensure that you would receive no more than a second-degree burn. It is important to remember that incident energy decreases with distance so if you have room to spare why not set up your barricades greater than the Arc Flash Boundary. A second-degree burn is still a burn.

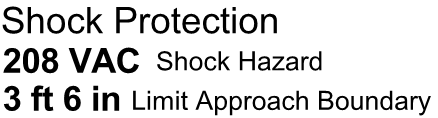

Shock Protection:

This section will give you the information on the voltage at the equipment, here it is 208 VAC, and what the distance that folks who are unqualified must stay behind unless accompanied by a qualified person. This would also be the distance that the work zone barricades are set up given it is greater than the Arc Flash Boundary discussed above.

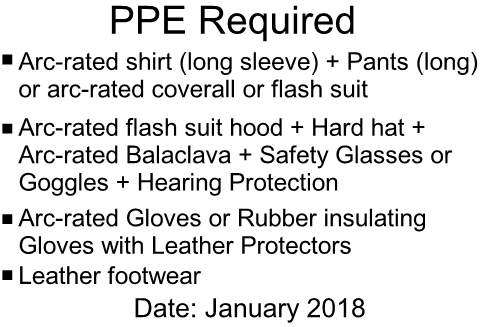

PPE Required:

The “PPE Required” section is going to tell you what PPE (Personal Protective Equipment) qualified workers need to be wearing when entering the Arc Flash Boundary if exposed energized parts are present or if you are performing work on that particular piece of equipment such as switching or racking a breaker in or out. This information is going to vary based off of the incident energy and the “Minimum Arc Rating of Clothing” section discussed earlier. Although not required we included the date of the study, which provides information on when the study was conducted; remember the study needs to be updated every 5 years or if any major changes take place within your system!

Equipment Name:

The last section on the label will tell you what the piece of equipment is called and should match up with your energized work permit and one-line drawings. Use this as a last safe guard to make sure that you are in the right place and about to perform work on the correct piece of equipment.

About the author

Jason Mazzola is the Director of Electrical Safety Services for Southern New England out of our Mansfield, MA office. He joined Hallam-ICS in 2019 and prior to that spent 10 years in utility industry in various engineering and leadership roles.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Six Actions to Take When Starting a New Technical Role

You Talkin’ ‘Bout Me?

No Comments Yet

Let us know what you think