FOOD & BEVERAGE

TECHNICAL EXPERTISE WITH A KEEN ATTENTION TO QUALITY

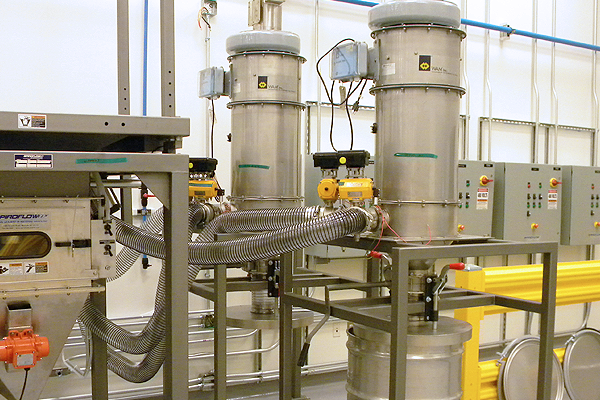

From process automation and sanitary design to regulatory compliance, we deliver tailored engineering solutions to optimize production, ensure safety, and drive sustainability. We understand your goals to enhance production efficiency while maintaining and improving product quality and consistency. Our engineers and process control experts can help reduce operational costs through automation and energy-efficient systems.

Years In The Industry

Food & Beverage Clients

Projects Completed or In-Progress

SPECIALTIES

Facility, Utility Process Systems

FDA & USDA Regulated Facilities

Batch, Continuous & Discrete Processing

Combustible Dust Locations

Process, Central Plant Utility Design

HVAC & Utility Systems

Facility Layout & Expansion

Clean-in-Place Systems

Control System Retrofits

Ready to Elevate Your Food & Beverage Operations?

SOLUTIONS FOR FOOD & BEVERAGE INDUSTRY

You count on your MEP engineering and plant automation partners to help fulfill your mission to provide a safe and consistent product. Hallam-ICS excels in this environment through our people, processes and technology to deliver solutions that contribute to your reputation and bottom line.

MECHANICAL, ELECTRICAL + PROCESS ENGINEERING

MECHANICAL, ELECTRICAL + PROCESS ENGINEERING

PROCESS CONTROLS

PROCESS CONTROLS

COMMISSIONING & VALIDATION

COMMISSIONING & VALIDATION

COMBUSTIBLE DUST SAFETY

COMBUSTIBLE DUST SAFETY

MANUFACTURING INTELLIGENCE

MANUFACTURING INTELLIGENCE

MECHANICAL, ELECTRICAL + PROCESS ENGINEERING

As partners in innovation and efficiency, we help clients achieve operational excellence while meeting industry standards. We have expert knowledge of production processes such as batching, mixing, pasteurization, packaging, and clean-in-place (CIP) systems, as well as an understanding of sanitary design principles to prevent contamination.

Hallam-ICS MEP engineering services include:

- Process System Design

- Equipment Specification

- Clean-in-Place System Design

- Power Distribution

- HVAC – industrial ventilation, heating and cooling plants

- Building Electrical Systems Design

PROCESS CONTROLS

Our PLC + SCADA programming services ensure seamless automation and control of your industrial processes. We excel in HMI/SCADA programming, ensuring intuitive and efficient human-machine interfaces. From system design to start-up and validation, we ensure your control systems are robust, reliable, and compliant with industry standards, enhancing operational efficiency and reducing downtime.

Hallam-ICS PLC and SCADA services include:

- GAMP Specification Development

- Control System Design

- PLC/PAC/DCS Programming

- HMI/SCADA Programming

- System Installation

- Start-Up and Validation

- Automation with Batch/S88

- Facility Management Systems

- Plant PAx Systems

COMMISSIONING & VALIDATION

We utilize our specialized engineering, control integration, and regulations expertise to test, validate and document systems to ensure that designs and implementations adhere to stringent safety, hygiene GMP standards.

Our commissioning & validation services include:

- HVAC and Control Systems

- Electrical Power Distribution

- Lighting

- Regulatory Compliance

- Computer System Validation

- Computer Software Assurance

- Automated System Validation

- Equipment and Instrument Validation

COMBUSTIBLE DUST SAFETY

If you have combustible dust in your facility, you need specialized technical knowledge to protect your employees and facility from the hazards of dust fires, flash fires, and explosions. From navigating the complex codes and standards, to interfacing with code authorities and insurers, our team of experts can support you every step of the way.

Our combustible dust safety services include:

- Dust Hazard Analysis

- Enhanced DHA Services

- Mitigation

- Dust Collection Systems

MANUFACTURING INTELLIGENCE

Our manufacturing intelligence services enhance productivity and help you maintain a competitive edge by leveraging your data. We provide a variety of development and integration services to capture and analyze critical process data. Gain actionable insight through reports and dashboards, while data analytics help you optimize processes, reduce costs, and improve decision-making through operational efficiency.

Hallam-ICS’s manufacturing intelligence services include:

- Database Design and Integration

- Historian Installation and Configuration

- Application Development

- Reports and Dashboards

- Data Analytics

- Front Office Systems Integration (e.g., SAP)

- Manufacturing Execution System (MES) Development and Deployment

- Overall Equipment Efficiency (OEE)

- 21 CFR Part 11 Applications

SUCCESS WITH HALLAM-ICS

We provide timely and budget-conscious solutions, strong project management and bring expertise and experience to the table.

CASE STUDY

Ignition SCADA Programming

CASE STUDY

Wet Process Control System

CASE STUDY

Automated Recipe Interface

CASE STUDY

Non-Dairy Equipment Installation

CASE STUDY

New Manufacturing Facility

CASE STUDY

Overall Equipment Effectiveness

CASE STUDY

Packaging Line Isolation

CASE STUDY

Plant-wide control system re-commissioning

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional solutions for food and beverage manufacturing applications.

The Comprehensive Guide to Dust Hazard Analysis and OSHA Compliance

Upgrading Your Obsolete Control System While Keeping Your Plant Running

OUR TAILORED APPROACH

From soup to nuts, from coffee to bacon, and from baby formula to ice cream, our tailored approach ensures that our solutions are perfectly aligned with your unique processing, mixing, and packaging requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

Why In-Person Engineering Reviews Still Matter

Passive House for Non-Residential Buildings