INDUSTRIAL PROCESS

HELPING CLIENTS IMPROVE OPERATIONS

We engineer solutions for Industrial Process facilities. Greenfield or retrofit, we take the time to ask questions and understand your objectives. Our approach, combined with in-depth knowledge of production processes and various equipment, result in solutions that turn new clients into repeat clients.

SPECIALTIES

Hallam-ICS engineers are the hands-on type who are most comfortable walking down a system or talking with an operator to gain valuable insight into a process before recommending solutions. This “boots on the ground” approach leads to cost effective and practical solutions that might have been missed otherwise.

Equipment Layout & Specification

Facility, Utility, & Process Systems

Material Handling

Dust Collection & Combustible Dust Safety

Batch, Continuous, Discrete Processing

Process Evaluation & Optimization

Power Distribution

PLCs, Automation, & Instrumentation

Arc Flash Study & Electrical Safety

Overall Equipment Effectiveness (OEE)

Machine Design & Fabrication

Code Analysis & Compliance

Let us know how we can help you solve your problems.

SOLUTIONS FOR INDUSTRIAL PROCESS

Industrial facilities typically have two kinds of problems – those that hurt PROFITABILITY, and those that pose a SAFETY risk. Whether you need to increase production, reduce waste, or improve safety, our engineers leverage their industrial experience to help solve your problems.

PROCESS ENGINEERING

PROCESS ENGINEERING

MECHANICAL ENGINEERING

MECHANICAL ENGINEERING

ELECTRICAL ENGINEERING

ELECTRICAL ENGINEERING

PROCESS AUTOMATION & CONTROLS

PROCESS AUTOMATION & CONTROLS

COMBUSTIBLE DUST SAFETY

COMBUSTIBLE DUST SAFETY

PROCESS ENGINEERING

Safety is our Ethos. Our process engineering services focus on safe processes and workplaces. Whether material is solid, liquid, or gas, toxic, corrosive, or flammable, we store, distribute, and dispose of your process streams in a safe and controlled manner. We specialize in designing efficient, and scalable process systems, specifying and procuring equipment, and supporting smooth integration through commissioning and startup support.

Our process engineering services include:

- Heat and/or Mass Balance complete with Process Flow Diagrams (PFD’s), Piping & Instrumentation Diagrams (P&ID’s)

- Equipment Specification including Bid Solicitation, Analysis, & Recommendations

- Process evaluation & optimization including Equipment Capacity Review, Identify Bottlenecks and Identify & Evaluate Options for Improvement

- Dust Hazard Analysis (DHA)

MECHANICAL ENGINEERING

Crucial for manufacturing operations, our engineers focus on improving integrated systems and optimizing complex processes.

Our mechanical engineering services include:

- Equipment Installation, Replacements, Upgrades, & Plant Expansions

- Detailed Design of Utilities, Material Handling, & Air Systems

- Machine & Custom Equipment Design, Modifications & Improvements for Special Applications

- Combustible Dust Hazard Mitigation for Code & Safety Compliance

ELECTRICAL ENGINEERING

Our design, implementation, and maintenance programs of the electrical systems within industrial plants, especially with continuous production processes, ensure reliable power delivery to machinery, automation systems, and critical process controls.

Our electrical engineering services include:

- Low & Medium Voltage Power Distribution including Transformers, MCC design & specification, Switchgear design & specification, Protective relaying

- AC & DC Drives & Controls Arc Flash Studies, Mitigation, & Safety Training

- Substation SCADA - PLC’s & Level 2+ Control Code & Safety Compliance

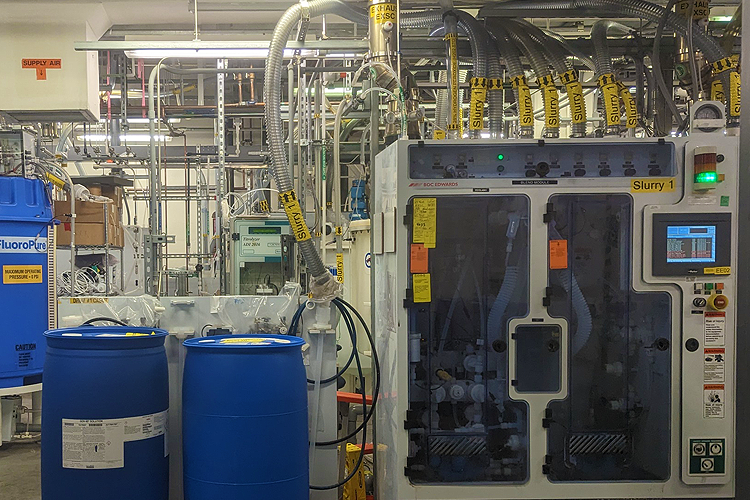

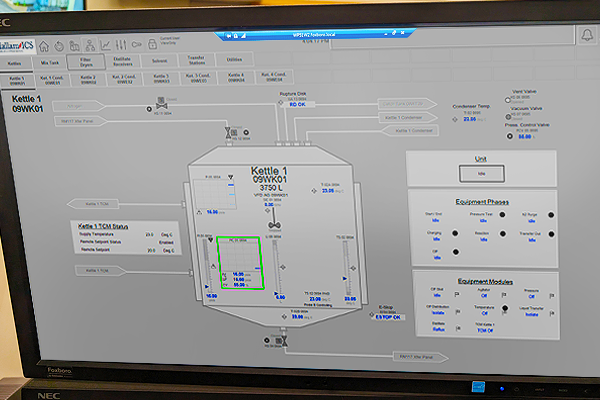

PROCESS AUTOMATION AND CONTROLS

Our PLC + SCADA programming services ensure seamless automation and control of your industrial processes. We excel in HMI/SCADA programming, ensuring intuitive and efficient human-machine interfaces. From system design to start-up and validation, we ensure your control systems are robust, reliable, and compliant with industry standards, enhancing operational efficiency and reducing downtime.

Hallam’s PLC & SCADA programming services include:

- GAMP Specification Development

- Control System Design

- PLC/PAC/DCS Programming

- HMI/SCADA Programming

- System Installation

- Start-Up and Validation

COMBUSTIBLE DUST SAFETY

If you have combustible dust in your facility, you need specialized technical knowledge to protect your employees and facility from the hazards of dust fires, flash fires, and explosions. From navigating the complex codes and standards, to interfacing with code authorities and insurers, our team of experts can support you every step of the way.

Our combustible dust safety services include:

- Dust Hazard Analysis

- Enhanced DHA Services

- Mitigation

- Dust Collection Systems

SUCCESS WITH HALLAM-ICS

Often called on to solve the most complicated challenges in a facility, Hallam-ICS is known for breaking down the barriers to improvement and success with engineered solutions.

CASE STUDY

Mechanical Engineering Support

CASE STUDY

Overall Equipment Effectiveness

CASE STUDY

Process Control System

CASE STUDY

Process Control for Sort Centers

CASE STUDY

Support Projects World-wide

CASE STUDY

WasteWater Re-piping

CASE STUDY

Anaerobic Digester Installation

CASE STUDY

Talc Ore Processing

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional solutions for industrial process applications.

Upgrading Your Obsolete Control System While Keeping Your Plant Running

The Comprehensive Guide to Dust Hazard Analysis and OSHA Compliance

Frequently Asked Questions

Industrial process engineering and automation solutions are the facility, utility, process, and control systems that improve production performance while reducing waste and safety risk. Hallam-ICS supports greenfield and retrofit projects by combining hands-on process understanding with engineering and controls to deliver practical, cost-effective improvements.

Industrial process facilities commonly include biomass & biofuels, chemicals & plastics, pulp & paper, building products, energy & power, steel & metals, cement, mining & minerals, and wood pellets. Hallam-ICS engineers support these environments with engineering, controls, safety, and compliance services tailored to the process and equipment.

Improvement typically starts with a process evaluation and optimization effort—capacity reviews, bottleneck identification, and options analysis—followed by engineered changes to equipment, utilities, controls, or material handling. Hallam-ICS takes a “boots on the ground” approach to find practical improvements that operators will actually use.

A process evaluation and bottleneck analysis reviews equipment capacity, constraints, and operating data to identify what’s limiting throughput or causing scrap/rework—then ranks improvement options by impact and cost. Hallam-ICS performs these assessments and turns them into actionable engineering and controls upgrades.

PLC + SCADA programming typically includes control system design, PLC/PAC/DCS programming, HMI/SCADA development, installation support, and startup/validation as needed. Hallam-ICS builds robust, reliable, and compliant control systems to improve uptime, safety, and operational visibility.

Yes. Many plants modernize controls through phased cutovers and staged commissioning to protect uptime. Hallam-ICS plans upgrades around production constraints so you can reduce downtime risk while improving reliability, safety, and maintainability.

OEE (Overall Equipment Effectiveness) measures availability, performance, and quality—helping teams pinpoint why a line isn’t producing at its true capacity. Hallam-ICS improves OEE by stabilizing sequences, improving alarm strategy, integrating data collection, and delivering dashboards that drive action.

An arc flash study analyzes electrical systems to quantify incident energy and define protective measures (labels, boundaries, PPE) for safer work. Hallam-ICS supports arc flash studies, mitigation, and safety training—especially important in continuous production facilities with complex power distribution.

Yes. Industrial electrical scopes often include low and medium voltage distribution (transformers, MCCs, switchgear, protective relaying), drives and controls, and substation SCADA/PLCs. Hallam-ICS designs and supports these systems to keep power reliable for machinery, automation, and critical controls.

A DHA identifies where combustible dust hazards exist and recommends safeguards to prevent dust fires, flash fires, and explosions. If combustible dust is present, specialized knowledge is needed to navigate codes/standards and interface with authorities and insurers. Hallam-ICS provides DHA, enhanced DHA services, mitigation, and dust collection system support.

It means starting with field walkdowns and operator input—walking down systems, understanding constraints, and validating how the process actually runs before recommending changes. Hallam-ICS uses this approach to deliver cost-effective solutions that don’t look good only on paper.

If you share your facility type, key constraints (throughput, waste, safety, downtime), and timeline, the Hallam-ICS team can recommend the right engineering, controls, and safety scope—then map a clear path to budget and schedule.

OUR TAILORED APPROACH

Whether you are an industrial processing plant, in an energy, power & fuels industry, a semiconductor manufacturer, or a mining operation, our tailored approach ensures that our solutions are perfectly aligned with your unique requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

Why In-Person Engineering Reviews Still Matter

Passive House for Non-Residential Buildings