LIFE SCIENCES

ENGINEERING SOLUTIONS FOR SUCCESS IN LIFE SCIENCES

When precision and compliance are non-negotiable, you need a partner who understands the critical balance between innovation and regulation. Whether you are engaged in benchtop research, complex manufacturing, or anywhere in between, you require engineered solutions that meet stringent regulatory standards and deliver reliable, repeatable results. With over 35 years of experience in GxP environments, our team provides the expertise, timeline management, and integration services necessary to safeguard product quality, patient safety, and data integrity, allowing you to focus on advancing medical breakthroughs.

Years Serving Life Sciences Clients

Life Sciences Clients

Projects Completed or In-Progress

SPECIALTIES

FDA-Regulated Facilities

cGMP Facilities

GMP Validation Areas + Systems

Environmental Monitoring Systems

21 CFR Part 11 Compliant Process Control Systems

Bio-Safety + Cleanroom R&D Facilities

Hazardous Locations

Combustible Dust Locations

Process + Central Plant Utility Design

Accelerate your medical innovation with streamlined processes.

SOLUTIONS FOR LIFE SCIENCES

Our team of engineers, control system integrators, instrumentation technicians, commissioning and validation experts, and arc flash electrical safety specialists have over three decades of Life Science expertise. With a practical understanding of regulatory standards and a focus on the big picture, we’ll ensure that your operation is not only compliant, but more importantly: safe.

MECHANICAL, ELECTRICAL + PROCESS ENGINEERING

MECHANICAL, ELECTRICAL + PROCESS ENGINEERING

PROCESS CONTROL SYSTEMS

PROCESS CONTROL SYSTEMS

MAIN INSTRUMENT VENDOR

MAIN INSTRUMENT VENDOR

COMMISSIONING, VALIDATION + QUALIFICATION

COMMISSIONING, VALIDATION + QUALIFICATION

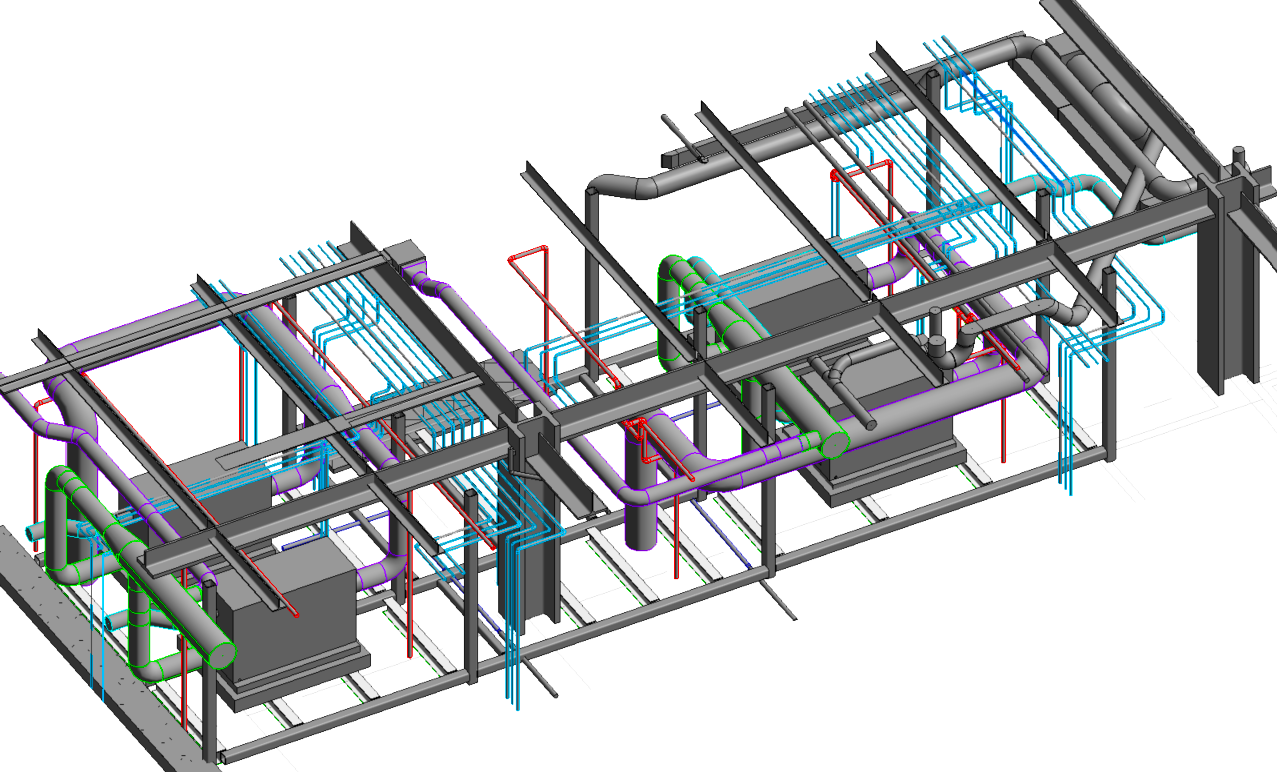

MECHANICAL, ELECTRICAL + PROCESS ENGINEERING

We provide precision engineering and project management on every project. Our teams can work alongside other experts for a single system or lead your engineering and process solutions end-to-end, from initial design through operational lifecycle. Our engineering expertise are focused on Good Manufacturing Process (GMP) validation areas, Bio-Safety research settings, cleanrooms, vivarium, and hazardous locations including hazardous dust.

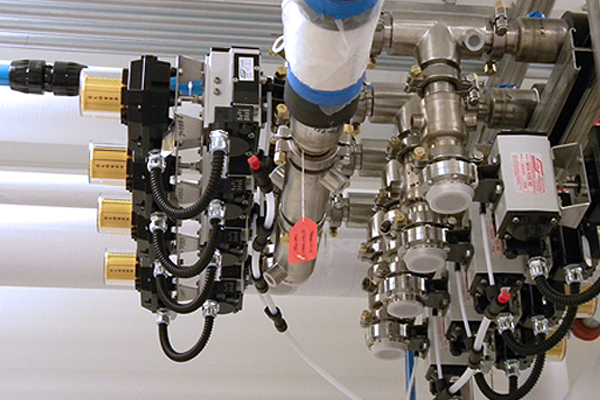

PROCESS CONTROL SYSTEMS

Often called on to solve the most complicated challenges in a facility, Hallam-ICS is known for breaking down the barriers to improvement and success – we can design, build, and program your automation system from start to finish. Our strengths within process controls and plant automation include Batch/S88, facility management, and Plant PAx system.

MAIN INSTRUMENT VENDOR

Our unique combination of engineering, automation, installation, and validation experience provides us with a deep understanding of the needs of our clients from instrument specification through bench testing, installation, field calibration and Turnover Package (ETOP) development.

From procurement and receiving to final delivery, we have the personnel power, cash flow, infrastructure and procedures in place in order to handle a vast project. By engaging Hallam-ICS as a Main Instrument Vendor (MIV) early in the project clients have the advantage of avoiding delays and unnecessary errors in order to stay on track and on budget.

COMMISSIONING, VALIDATION + QUALIFICATION

Our commissioning and validation support Good Manufacturing Practice (GMP) settings, and ensure documented evidence that equipment, software, and instruments used in the manufacture of pharmaceuticals, biologics, and medical devices are fit for use and will provide repeatable functionality.

SUCCESS WITH HALLAM-ICS

Life sciences clients benefit from our engineering expertise, responsiveness, and project management.

CASE STUDY

New Clinical Manufacturing Facility

CASE STUDY

Project Inspire – Durham Clinical Manufacturing Facility

CASE STUDY

Chiller Upgrade Engineering Design

CASE STUDY

New Laboratory Engineering Design

CASE STUDY

B156A Chemistry Labs MEP Engineering Design

CASE STUDY

Siemens Medical Solutions Diagnostics

CASE STUDY

New Manufacturing Facility Instrument Calibration

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional solutions for life science applications.

OUR TAILORED APPROACH

When the health and safety of individuals is at stake, you need a partner who understands the nuances of your industry. At Hallam-ICS, our tailored approach to the life science industry is based on over 35 years of providing engineering, control systems, and validation solutions that solve the most complex challenges in labs and production facilities. We listen to your goals and come to the table with expertise to engineer a timely solution that safeguards product quality, patient safety, and data integrity. Whether you are engaged in benchtop research or complex manufacturing, our team is equipped to support your facility at every stage, from inception to production.

We follow our proprietary CODES™ process — COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE — to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

Validation in Life Sciences Projects: Ensuring Compliance and Safety

Cleanroom Commissioning: Ensuring Precision, Performance, & Compliance