ADVANCED RESEARCH

ENGINEERING SYSTEMS TO SUPPORT RESEARCH & EDUCATION

We focus on designing and optimizing systems and environments where precision, reliability, innovation, and safety are paramount. By integrating engineering expertise and regulatory compliance, Hallam-ICS supports the advanced research industry in creating state-of-the-art facilities - home to solutions of the future.

Years Serving Advanced R&D Clients

R&D & Higher Education Clients

In Completed or In-Progress Projects

SPECIALTIES

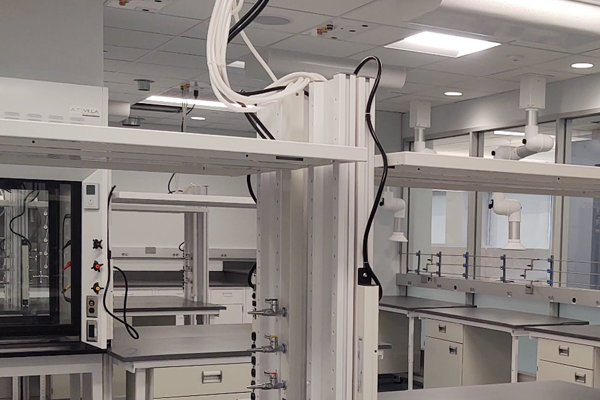

Concealed behind the striking architectural designs, and unnoticed by many, lies the mechanical and electrical infrastructure that consistently operates, ensuring student comfort and enabling researchers to conduct essential experiments. This is the realm of Hallam-ICS; MEP engineering specialists who design and implement systems that are durable, dependable, and energy-efficient.

Toxic Gas Monitoring Systems

Bio-Safety R&D Facilities

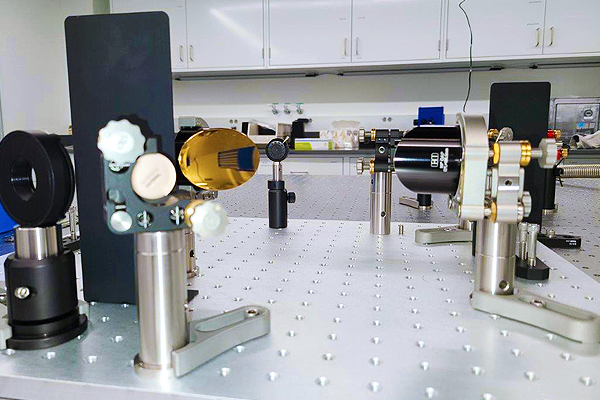

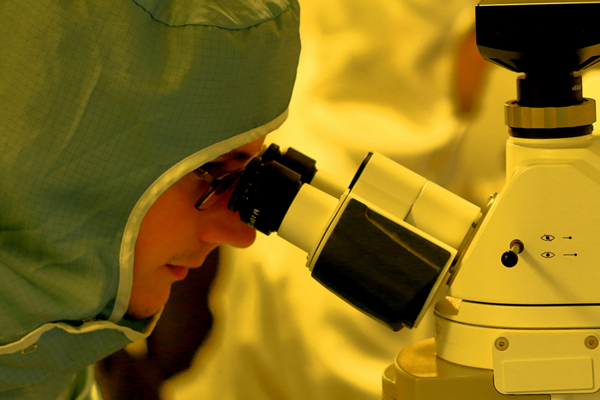

Cleanroom R&D Facilities

Building & Utility Systems

Gas & Chemical Distribution

Lab Design & Renovation

LEED Certification

GLP Facilities

Vivariums

We deliver tailored solutions for cutting-edge facility designs

SOLUTIONS FOR ADVANCED RESEARCH

In partnership with campus planners, facility directors, and energy managers, Hallam-ICS has assisted institutions in designing new research facilities, conducting arc flash studies to ensure worker safety, commissioning new construction, and renovating existing labs and spaces, making use of existing equipment when feasible while consistently considering energy expenses.

MECHANICAL ENGINEERING

MECHANICAL ENGINEERING

ELECTRICAL ENGINEERING

ELECTRICAL ENGINEERING

PROCESS ENGINEERING

PROCESS ENGINEERING

TOXIC GAS MONITORING

TOXIC GAS MONITORING

COMMISSIONING & VALIDATION

COMMISSIONING & VALIDATION

MECHANICAL ENGINEERING

Efficient Design and Efficient Operation. Our Mechanical engineering team delivers HVAC designs for office spaces to ISO-5 and beyond, including state of the art energy recovery systems and energy efficient sequences of operation, in some of the most challenging locations.

Our mechanical engineering services include:

- HVAC – industrial ventilation, heating and cooling plants

- Precision Temperature and Humidity control for critical environments

- Plumbing and Fire Protection

- Cleanrooms to ISO-5/ Class 100

- Hazardous exhaust systems

- Laboratory Ventilation systems

- Piping – steam, chilled water, compressed air, refrigeration

- Energy Modeling

ELECTRICAL ENGINEERING

Providing comprehensive solutions for power distribution, motor controls, and advanced lighting systems, our electrical engineering systems ensure optimal performance. We prioritize safety and efficiency through detailed coordination studies, short circuit analysis, and arc flash studies, tailored to meet the unique demands of your facility.

Our electrical engineering services include:

- Site wide Utility Upgrades

- Electrification studies

- Electrical Power Distribution

- Classified Area analysis and design

- Motor Controls

- Energy Efficiency upgrades

- Lighting and Lighting Control

- Daylight Harvesting

- Coordination Studies

- Short Circuit AnalysisArc Flash Studies

- Electrical Systems Analysis

- Lightning Protection

- Harmonics Mitigation

PROCESS ENGINEERING

Safety is our Ethos. Our process engineering services focus on safe processes and workplaces. Whether material is solid, liquid, or gas, toxic, corrosive, or flammable, we store, distribute, and dispose of your process streams in a safe and controlled manner. We specialize in designing efficient, and scalable process systems, specifying and procuring equipment, and supporting smooth integration through commissioning and startup support.

Our process engineering services include:

- Process Hazard Analysis/Failure Mode Effects Analysis (PHA/FMEA)

- Dust Hazard Analysis (DHA)

- Code reviews/Code Consulting

- Ultra-pure water systems

- Hazardous Production Material (HPM) distribution

- Process Exhaust

- Cryogenics

- Instrumentation procurement and delivery

- Commissioning, Validation & Startup Support

TOXIC GAS MONITORING & CONTROLS

Our Toxic Gas safety platforms can be adapted to ongoing changes in Hazardous Production Material (HPM) gas targets and materials, allowing your R&D to thrive in a safe facility.

Our toxic gas monitoring services include:

- Studies, System Audits & Reviews

- Code Reviews & Requirements Definition

- System Design & Layout

- System Requirements Definition

- Equipment Specification & Recommendation

- Panel Fabrication

- Systems Integration & Installation

- Construction Management

- Information Management

- Commissioning & Start-up

COMMISSIONING & VALIDATION

We utilize our specialized engineering, control integration, and regulations expertise to test, validate and document systems to ensure that designs and implementations adhere to stringent safety, hygiene GMP standards.

Our commissioning & validation services include:

- HVAC and Control Systems

- Electrical Power Distribution

- Lighting

- Regulatory Compliance

- Computer System Validation

- Computer Software Assurance

- Automated System Validation

- Equipment and Instrument Validation

SUCCESS WITH HALLAM-ICS

Hallam-ICS engineers work together effectively, adapt quickly, and are versatile to address your diverse requirements.

CASE STUDY

Commissioning & LEED Certification

CASE STUDY

Commissioning & LEED Certification

CASE STUDY

Site-Wide Toxic Gas Monitoring

CASE STUDY

Base Building and Fit-up Phases

CASE STUDY

Engineering Design For A Microscope Suite

CASE STUDY

Process Gas and Gas Monitoring

CASE STUDY

Commissioning

CASE STUDY

MEP Engineering Design And Install

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional solutions for advanced research applications.

How to Create a Safety Requirement Spec for a Toxic Gas Monitoring System

OUR TAILORED APPROACH

Whether your research is in semiconductors and nano technology, new materials, health, medicine or safety, our tailored approach ensures that our solutions are perfectly aligned with your unique requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

Why In-Person Engineering Reviews Still Matter

Passive House for Non-Residential Buildings