TURNKEY SOLUTIONS

PROVIDING READY TO DEPLOY SOLUTIONS TAILORED TO YOUR NEEDS

Hallam-ICS provides comprehensive turnkey solutions that offer fully integrated and customized engineering, control systems, and installation services. Specializing in clean room systems, toxic gas and chemical distribution, FDA-regulated and GMP facilities, BAS/FMCS, and environmental monitoring, we ensure seamless execution for the most complex projects. We deliver complete, end-to-end solutions specifically tailored to meet unique requirements. From the initial concept to implementation, our precision-engineered solutions adhere to stringent industry codes and standards while optimizing both efficiency and functionality.

TURNKEY SOLUTIONS

By managing every stage of the process — from design and engineering to installation, automation, and commissioning — Hallam-ICS ensures seamless implementation and minimizes project risks. Our customized solutions enhance operational efficiency, ensure regulatory compliance, and reduce downtime, helping clients in high-tech industries achieve reliable and optimized performance. With Hallam-ICS as a single point of contact, clients save time, reduce costs, and gain access to expert support tailored to their specific needs, enabling them to focus on their core business objectives.

SUBCONTRACTOR MANAGEMENT

SUBCONTRACTOR MANAGEMENT

INSTRUMENTATION, DESIGN, PROCUREMENT, & INSTALLATION

INSTRUMENTATION, DESIGN, PROCUREMENT, & INSTALLATION

MEP DESIGN/BUILD PARTNER

MEP DESIGN/BUILD PARTNER

TOXIC GAS MONITORING & CONTROLS

TOXIC GAS MONITORING & CONTROLS

SUBCONTRACTOR MANAGEMENT

Hallam-ICS provides comprehensive subcontractor management services to ensure seamless coordination and successful project execution. We help clients mitigate risks, maintain quality, and achieve efficient coordination with subcontractors, ensuring successful project outcomes.

Our subcontractor management services include:

- Subcontractor Selection and Evaluation

- Scope Definition

- Contract Development

- Project Coordination

- Safety Oversight

- Quality Assurance

- Communication and Reporting

- Change Management

- Performance Monitoring

- Closeout and Documentation

INSTRUMENTATION, DESIGN, PROCUREMENT, & INSTALLATION

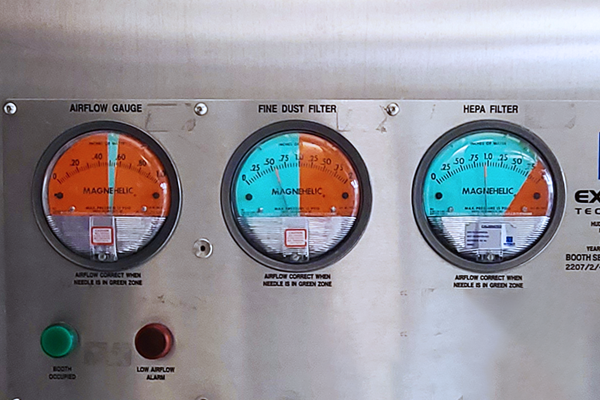

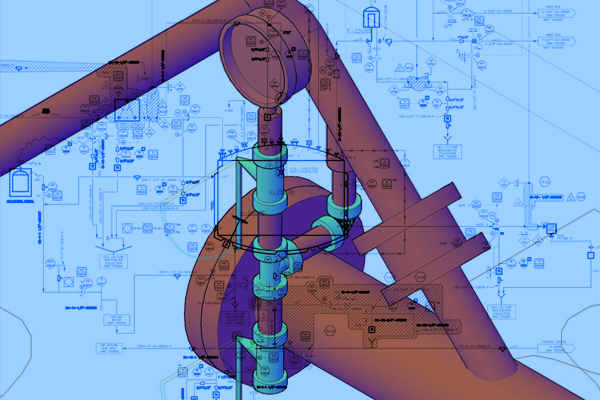

We provide a comprehensive suite of services for Instrumentation, Design, Procurement, and Installation (IDPI) to ensure precise control and seamless operation of complex systems. We ensure our clients receive a fully functional and optimized instrumentation and control system tailored to their specific needs.

Our IDPI services include:

- Instrumentation Selection

- Calibration Services

- Functional Specification Development

- Control System Design

- Panel Design and Layout

- P&ID Development

- Vendor Evaluation and Selection

- Cost Management

- Logistics Coordination

- Field Installation

- System Integration

- Commissioning and Start-Up

MEP ENGINEERING DESIGN/BUILD PARTNER

We provide comprehensive services as a Mechanical, Electrical, and Plumbing (MEP) Design/Build partner by integrating engineering expertise, construction management, and client collaboration to deliver fully functional and optimized systems.

Our approach includes:

- Custom MEP System Design

- Building Information Modeling (BIM)

- Energy Efficiency Optimization

- Seamless Integration of Design and Construction

- Construction Management

- Prefabrication Services

- Early Client Involvement

- Single Point of Contact

- Value Engineering

- System Installation

- Commissioning Services

- Post-Installation Support

TOXIC GAS MONITORING & CONTROLS

We provides toxic gas monitoring (TGM) services as one of our turnkey solutions by offering comprehensive expertise in designing, implementing, and supporting robust gas detection systems to ensure safety in high-tech environments. Our expertise in managing toxic gas hazards enable us to deliver peace of mind by ensuring a safe working environment, minimizing risks, and meeting stringent regulatory requirements and allowing clients to focus on their core operations.

Our toxic gas monitoring services include:

- System Design and Engineering for Customized Solutions

- Comprehensive Risk Assessment

- Integration with Building Systems

- Equipment Specification and Procurement

- Installation, Calibration and Commissioning

- Alarm and Notification Systems

- Emergency Integration

- Maintenance and Support

- Systems Upgrade

- Compliance and Training

WHY HALLAM-ICS?

Reducing Risk, Accelerating Success

By offering end-to-end design and construction services, we reduce your project risks and shorten timelines. We deliver high-quality systems and our collaborative approach ensures that your functional, operational, and budgetary requirements are met.

Mastery in Managing Hazardous Materials

From cleanrooms to sub-class 1 facilities, our team is adept at designing systems that manage hazardous materials including chemical storage and delivery, as well as toxic gas monitoring and control. Our comprehensive understanding of regulatory requirements and best practices ensures personnel and environmental safety.

Nimble Solutions for Any Location

Our deep technical knowledge equips us to handle projects of varying complexity both large and small. With eight locations across the country, we provide the nimble ability to respond quickly, ensuring timely, high-quality delivery and support wherever your project is located.

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional solutions for turnkey applications.

CASE STUDY

Toxic Gas Monitoring System

CASE STUDY

Helium Recovery System

CASE STUDY

Clean Utility System Controls Upgrade

CASE STUDY

Hydrogenator Upgrade

CASE STUDY

Controls, Instrumentation, and Installation

SUCCESS WITH HALLAM-ICS

Hallam-ICS engineers work together effectively, adapt quickly, and are versatile to address your diverse requirements.

Frequently Asked Questions

Yes. We excel in matching our clients' scope, scale, and regulatory profile. Hallam-ICS has delivered turnkey projects across Semiconductor, Life Sciences/Pharma, Advanced Manufacturing, Food & Beverage, and R&D cleanrooms - ranging from greenfield utilities and cleanroom expansions to validated process skids and controls upgrades. Our team integrates multidiscipline engineering, UL panel fabrication, PLC/SCADA, and commissioning/validation under one plan, coordinating vendors and contractors to hit cost, schedule, and quality targets.

Absolutely. Hallam-ICS builds compliance in from the start, aligning URS/FRS, risk assessments, and testing with FDA/GMP expectations and industry guidance. Commissioning artifacts roll into IQ/OQ/PQ to avoid duplicate testing and accelerate qualification.

Safety is engineered into the design (electrical safety, arc flash labeling, TGMS integration where relevant) and verified during FAT/SAT and functional testing. Hallam-ICS maintains job hazard analyses, lockout/tagout coordination, and start-up plans that protect people and production.

Expect a complete, version-controlled package: P&IDs and one-lines, I/O lists, control narratives, network drawings, panel schedules, alarm matrices, tested PLC/SCADA code, FAT/SAT records, training materials, spare parts lists, and maintenance/calibration procedures - structured for audits and day-to-day use.

Hallam-ICS uses clear Owner’s Project Requirements (OPR), a traceable Basis of Design (BOD), and phased deliverables (30/60/90) with change control. Cause-and-effect, I/O lists, and control narratives align design with automation and commissioning so scope stays stable and auditable.

Hallam-ICS offers phased, fixed-price milestones or GMP-style time & materials with not-to-exceed caps. Early constructability and vendor coordination de-risk the schedule; long-lead items are expedited via aligned procurement to protect critical path.

Yes. We manage vendor selection or integrate with your preferred OEMs/ECs, providing technical leadership, submittal/RFI management, and onsite coordination so the team executes one plan.

Yes. Our integration team designs PLC/SCADA architectures (e.g., Rockwell, Ignition), implements historian/reporting, and ties alarms/events to commissioning requirements - so operations get a validated, supportable system on day one.

You get a single point of contact, faster decisions, coordinated trades, and fewer gaps between design, automation, and commissioning. Hallam-ICS reduces risk and change orders by integrating engineering with controls and Cx/V early - delivering predictable cost, schedule, and performance.

Semiconductor fabs and suppliers, life sciences/pharma, advanced manufacturing, food & beverage, and R&D cleanrooms benefit from Hallam-ICS turnkey delivery - especially where complex utilities, safety interlocks, and data/quality requirements demand tight integration.

A turnkey engagement with Hallam-ICS covers the full lifecycle: front-end consulting and basis-of-design, multidiscipline engineering (process, MEP, electrical, I&C), control panel design/fabrication, PLC/SCADA development, installation coordination, commissioning & validation (IQ/OQ/PQ for regulated sites), documentation/training, and post-startup support - one accountable team from concept through handover.

OUR TAILORED APPROACH

Whether you are a semiconductor manufacturer, life sciences company, or industrial plant, our tailored approach ensures that our solutions are perfectly aligned with your unique requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

Why In-Person Engineering Reviews Still Matter

Passive House for Non-Residential Buildings