SEMICONDUCTORS

HELPING SEMICONDUCTOR CLIENTS ACCELERATE & SCALE

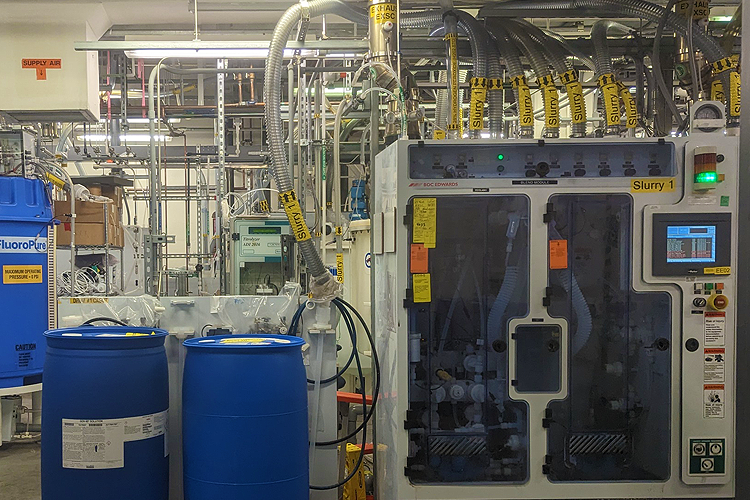

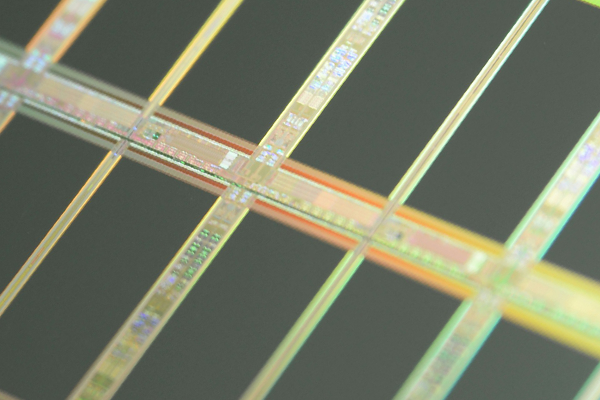

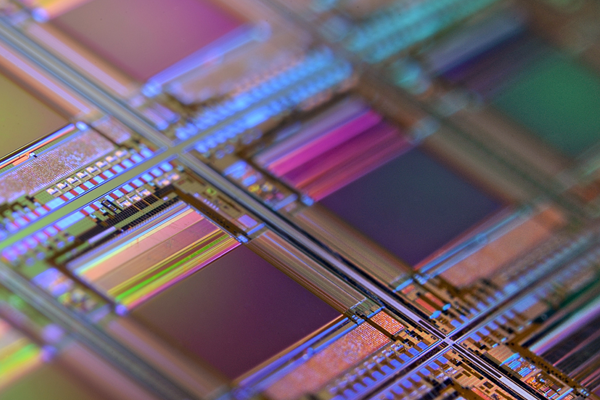

Hallam-ICS specializes in control systems and engineering solutions for hazardous materials and clean environments, having partnered with semiconductor companies for the last 35 years, from engineering base builds and tool installations to control solutions for chemical management and toxic gasses.

Years Serving Semiconductor Clients

Semiconductor Clients

In Completed or In-Progress Projects

SPECIALTIES

Process Tool Layout

Cleanroom Engineering Design

Central Utility Plant

Toxic Gas Monitoring Systems

Facility Management Control Systems

Process Tool Accommodation

HPM Gasses & Liquids Process Exhaust and Ventilation

HPM Storage & Delivery

Arc Flash Study & Electrical Safety

Let us apply our knowledge and expertise on your next project.

SOLUTIONS FOR SEMICONDUCTORS

We understand the unique needs of the semiconductor industry and, like our clients, we hold firm to a “no defect” policy in our designs and installations.

PROCESS ENGINEERING

PROCESS ENGINEERING

MECHANICAL ENGINEERING

MECHANICAL ENGINEERING

ELECTRICAL ENGINEERING

ELECTRICAL ENGINEERING

PROCESS CONTROL INTEGRATION

PROCESS CONTROL INTEGRATION

TOXIC GAS MONITORING & CONTROLS

TOXIC GAS MONITORING & CONTROLS

PROCESS ENGINEERING

Safety is our Ethos. Our process engineering services focus on safe processes and workplaces. Whether material is solid, liquid, or gas, toxic, corrosive, or flammable, we store, distribute, and dispose of your process streams in a safe and controlled manner. We specialize in designing efficient, and scalable process systems, specifying and procuring equipment, and supporting smooth integration through commissioning and startup support.

Our process engineering services include:

- Process Hazard Analysis/Failure Mode Effects Analysis (PHA/FMEA)

- Dust Hazard Analysis (DHA)

- Code Reviews/Code Consulting

- Ultra-pure Water Systems

- Hazardous Production Material (HPM) Distribution

- Process Exhaust

- Cryogenics

- Instrumentation Procurement and Delivery

- Commissioning, Validation & Startup Support

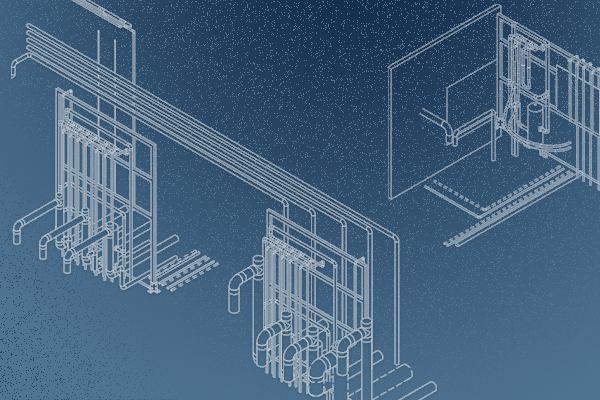

MECHANICAL ENGINEERING

Efficient Design and Efficient Operation. Our Mechanical engineering team delivers HVAC designs for office spaces to ISO-5 and beyond, including state of the art energy recovery systems and energy efficient sequences of operation, in some of the most challenging locations.

Our mechanical engineering services include:

- HVAC – industrial ventilation, heating and cooling plants

- Precision Temperature and Humidity control for critical environments

- Plumbing and Fire Protection

- Cleanrooms to ISO-5/ Class 100

- Hazardous Exhaust Systems

- Laboratory Ventilation Systems

- Piping – Steam, Chilled Water, Compressed Air, Refrigeration

- Energy Modeling

ELECTRICAL ENGINEERING

Providing comprehensive solutions for power distribution, motor controls, and advanced lighting systems, our electrical engineering systems ensure optimal performance. We prioritize safety and efficiency through detailed coordination studies, short circuit analysis, and arc flash studies, tailored to meet the unique demands of your facility.

Our electrical engineering services include:

- Site-wide Utility Upgrades

- Electrification Studies

- Electrical Power Distribution

- Classified Area Analysis and Design

- Motor Controls

- Energy Efficiency upgrades

- Lighting and Lighting Control

- Daylight Harvesting

- Coordination Studies

- Short Circuit Analysis

- Arc Flash Studies

- Electrical Systems Analysis

- Lightning Protection

- Harmonics Mitigation

PROCESS CONTROL INTEGRATION

We excel at delivering cutting-edge control systems tailored to the needs of semiconductor manufacturers and research facilities. We collaborate to deliver solutions that range from bulk and specialty gas equipment and distribution, to hazardous gas monitoring systems, to liquid chemical distribution, air pollution control, compressed air and failure modeling.

Our process control services include:

- Control System Design

- PLC Programming

- HMI and SCADA Development

- Process Automation Integration

- Batch Process Control

- Legacy System Upgrades

- Data Acquisition and Analytics

- Commissioning and Start-Up Support

- Validation

TOXIC GAS MONITORING & CONTROLS

Our Toxic Gas safety platforms can be adapted to ongoing changes in Hazardous Production Material (HPM) gas targets and materials, allowing your R&D to thrive in a safe facility.

Our toxic gas monitoring services include:

- Studies, System Audits & Reviews

- Code Reviews & Requirements Definition

- System Design & Layout

- System Requirements Definition

- Equipment Specification & Recommendation

- Panel Fabrication

- Systems Integration & Installation

- Construction Management

- Information Management

- Commissioning & Start-up

SUCCESS WITH HALLAM-ICS

Often called on to solve the most complicated challenges in a facility, Hallam-ICS is known for breaking down the barriers to improvement and success with engineered solutions.

CASE STUDY

Fab 8 Toxic Gas Monitoring System

CASE STUDY

Semiconductor Manufacturing Support

CASE STUDY

Site-wide Toxic Gas Monitoring

CASE STUDY

Silane System Installation

CASE STUDY

Base Building and Fitup Phases

CASE STUDY

New Silicon Carbide Wafers Fabrication Facility

CASE STUDY

Fabrication Facility

CASE STUDY

Fabrication and Characterization Facility

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional solutions for semiconductor applications.

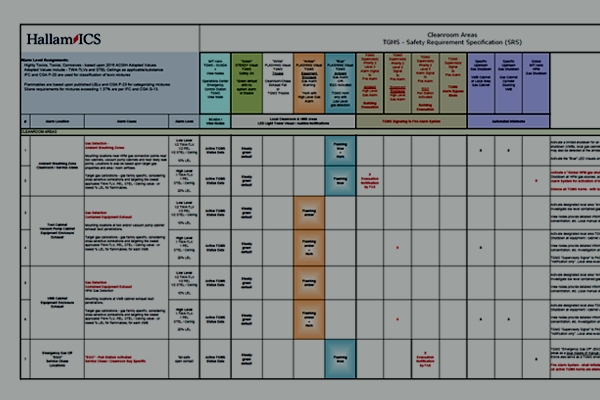

Cleanroom Areas TGM - Safety Requirement Specification (SRS) Matrix

Upgrading Your Obsolete Control System While Keeping Your Plant Running

Frequently Asked Questions

Semiconductor engineering and automation solutions are the facility, utility, safety, and control systems that keep fabs and clean environments stable and scalable—especially where hazardous materials and precision conditions are involved. Hallam-ICS supports base builds and tool installs with engineering and controls for chemical management and toxic gases.

Engineering services support semiconductor facilities by designing and upgrading the infrastructure behind uptime and yield—cleanroom HVAC, utilities, electrical distribution, and hazardous exhaust/ventilation. Hallam-ICS helps teams ramp and expand without impacting production by delivering buildable designs and practical startup support.

Process control connects fab utilities and safety systems to PLC/SCADA so teams can monitor, alarm, trend, and respond in real time. Hallam-ICS integrates control solutions that improve reliability and visibility for critical systems tied to production continuity.

FMCS (Facility Management Control System) is the control layer that monitors and manages facility utilities and conditions that impact cleanroom stability and production continuity. Hallam-ICS designs and integrates FMCS architectures with alarming, trending, and reliability built in.

A TGMS detects hazardous gases and triggers defined safety actions to protect personnel and operations. Hallam-ICS provides TGMS studies, audits, requirements definition, system design/layout, panel fabrication, integration/installation, and commissioning/startup support for semiconductor environments.

Safety and compliance start with defining requirements early, designing to applicable codes/standards, and verifying system performance through testing and commissioning—especially for toxic gases, chemical management, and high-risk utility systems. Hallam-ICS supports requirements definition and verification so projects stay inspection-ready and operationally reliable.

Turnkey delivery reduces handoff risk between engineering, controls, and startup. Hallam-ICS can provide one coordinated team across engineering, process control integration, toxic gas monitoring, and commissioning/startup—helping fabs move faster with fewer gaps and less rework.

Yes. Hallam-ICS has over 35 years of experience serving semiconductor clients, more than 100 semiconductor clients, and $250M in completed or in-progress projects. We also extensive experience in the field of toxic gas monitoring systems.

If you share your project type (base build, expansion, or tool install), hazard profile (chemicals/toxic gases), and timeline, the Hallam-ICS team can recommend the right engineering, controls, and safety scope—then map a clear path to budget and schedule.

OUR TAILORED APPROACH

Whether you are a semiconductor manufacturer, life sciences company, or industrial plant, our tailored approach ensures that our solutions are perfectly aligned with your unique requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

Why In-Person Engineering Reviews Still Matter

Passive House for Non-Residential Buildings