TOXIC GAS MONITORING SYSTEMS

TOP-TIER TOXIC GAS MONITORING SYSTEMS TO PROTECT WHAT'S MOST IMPORTANT

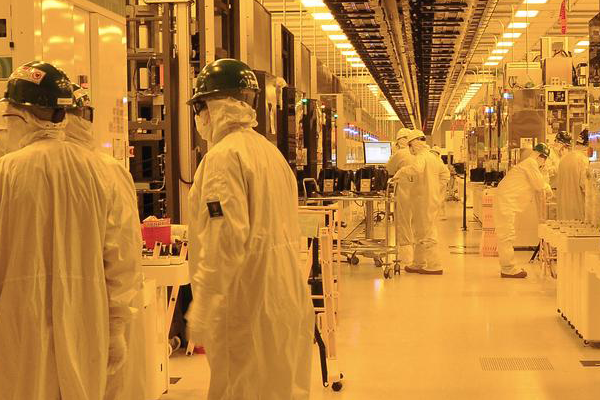

At Hallam-ICS, we develop industry-leading toxic gas monitoring systems (TGMS) to ensure semiconductor and nanotechnology facilities are safe and in compliance with all regulations. Our teams create reliable, secure, high-performance life safety systems and develop best practices. Our systems are easily adaptable to ever-changing hazardous gas target requirements which allows your research and development to thrive in a safe facility.

TOXIC GAS MONITORING SERVICES

At Hallam-ICS, our engineers care about your staff, your facility, and your goals. Success for our team is a working relationship that makes your life easier by protecting those priorities with an top-tier TGMS. From the toxic gas matrix development, to installation, we are equipped to handle the most challenging projects and environments.

TOXIC GAS MONITORING & CONTROLS

TOXIC GAS MONITORING & CONTROLS

SAFETY SHUTDOWN SYSTEMS

SAFETY SHUTDOWN SYSTEMS

FUNCTIONAL SYSTEMS

FUNCTIONAL SYSTEMS

TGMS SERVICE & MAINTENANCE PROGRAM DEVELOPMENT

TGMS SERVICE & MAINTENANCE PROGRAM DEVELOPMENT

SMALL LAB TOXIC GAS MONITORING SOLUTION

SMALL LAB TOXIC GAS MONITORING SOLUTION

TOXIC GAS MONITORING & CONTROLS

Our Toxic Gas safety platforms can be adapted to ongoing changes in Hazardous Production Material (HPM) gas targets and materials, allowing your R&D to thrive in a safe facility.

Our toxic gas monitoring services include:

- Studies, System Audits & Reviews

- Code Reviews & Requirements Definition

- System Design & Layout

- System Requirements Definition

- Equipment Specification & Recommendation

- Panel Fabrication

- Systems Integration & Installation

- Construction Management

- Information Management

- Commissioning & Start-up

SAFETY SHUTDOWN SYSTEMS

Using and subscribing to OSHA, NFPA, CGA, ICC, SEMI, SESHA and FM codes as our basis for user requirements, we work closely with customer stakeholders, EH&S personnel, and the local AHJ to ensure all potential gas related hazards are identified, monitored and proper safety actions are applied. Our systems keep facilities free from fears of dangerous exposures to toxicity, oxygen deficiency, fire, or explosion.

Our safety shutdown services include:

- Fire Alarms

- Smoke Detection

- Hazardous Process Gases & Chemicals

- Emergency Evacuation Systems

FUNCTIONAL SYSTEMS

Our gas safety platforms can be easily and and quickly adapted to the required ongoing changes to Hazardous Production Material (HPM) gas targets and materials, allowing your R&D to thrive in a safe facility.

Our functional systems services include:

- Detect Leaks in Hazardous Production Material Systems

- Initiate Evacuation Alarms & Building Appliances

- Shut Down or Activate Appropriate Facility Systems

- Shut Down Process Equipment

- Shut Down the HPM Source

TGMS SERVICE & MAINTENANCE PROGRAM DEVELOPMENT

Developing documentation of the maintenance, testing and inspections of the toxic gas monitoring system is a critical. Your TGM system is a tremendous investment that safe-guards your staff, facility and community, and it requires diligent maintenance to ensure that this important, life safety system is performing per specification.

Our TGMS service & maintenance program development services include:

- Document Control

- Inspections

- Recommissioning

- Filter Replacement

- Chemical Tape Changes

- Sensor Replacement

- Integration Support

- Gas Challenging and Calibration

SMALL LAB TOXIC GAS MONITORING SOLUTION

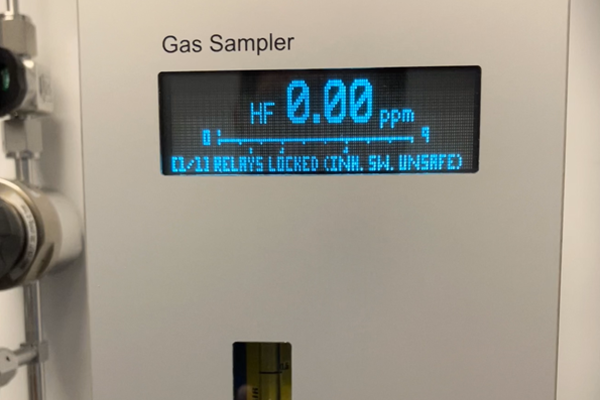

A robust functionality of larger TGMS systems in a compact package.

The Small Lab TGMS solution is designed specifically for small lab environments that use hazardous production materials (HPMs) or hazardous research materials (HRMs).

It provides comprehensive toxic gas monitoring and safety system but for a small lab environment.

The Small Lab TGMS solution is designed to be field-ready and interface with other safety systems.

It has the capacity to accept all required types of inputs and logically output the correct safety responses to these inputs, ensuring a comprehensive integration with other safety systems.

Small Lab TGMS solution main features:

- Up to 12 analog gas monitoring points

- Support for Ethernet enabled gas detection

- Real-time safety information

- Password protected user interface

- Live gas concentration trend graphs

- User-tunable safety responses

- Industrial grade Allen-Bradley PLC

- Internal Uninterruptable Power Supply (UPS)

- 7” Color touchscreen

- Open PLC and touchscreen programming code

- UL508A labelled control panel

WHY HALLAM-ICS?

Codes + Best Practices = SAFETY

Codes are only the minimum requirements and

they should never be used alone to design a

TGMS. For defining a safety requirement specification for any TGMS application we recommend an approach that will reference, consider and harmonize overlapping codes and utilize all resources AND best practices available. This approach allows us to create reliable, secure, high performance systems and reduce risk.

Mastery in Managing Hazardous Materials

From cleanrooms to sub-class 1 facilities, our team is adept at designing systems that manage hazardous materials including chemical storage and delivery, as well as toxic gas monitoring and control. Our comprehensive understanding of regulatory requirements and best practices ensures personnel and environmental safety.

Nimble Solutions for Any Location

Our deep technical knowledge equips us to handle projects of varying complexity both large and small. With eight locations across the country, we provide the nimble ability to respond quickly, ensuring timely, high-quality delivery and support wherever your project is located.

We Understand The Requirements of Toxic Gas Systems

We have longstanding relationships with diverse customers and a proven history of successfully applying Toxic Gas Monitoring Systems at major semiconductor manufacturing sites and university research facilities across the country.

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional engineering solutions in a variety of applications.

CASE STUDY

New Fab Toxic Gas Monitoring System

CASE STUDY

Sensidyne Gas Monitoring System

CASE STUDY

Fab 8 Toxic Gas Monitoring System

CASE STUDY

Silane System Installation

CASE STUDY

Site-Wide Toxic Gas Monitoring

SUCCESS WITH HALLAM-ICS

Clients across industries benefit from our engineering expertise, responsiveness, and project management.

Frequently Asked Questions

Hallam-ICS designs your toxic gas monitoring system in alignment with applicable codes and industry standards, including the International Fire Code (IFC), NFPA guidance (e.g., NFPA 55), SEMI standards (e.g., S2/S6), CGA documents, OSHA exposure limits, and the requirements of your local Authority Having Jurisdiction (AHJ). Our team works directly with your EHS group and the AHJ to establish compliant alarm thresholds and define the required safety actions.

Semiconductor fabs, R&D cleanrooms, nanotechnology labs, universities, and advanced manufacturing lines using hazardous production materials (HPM) typically need TGMS. The Hallam-ICS Team designs systems for gas cabinets, VMBs, gas bunkers, tool install areas, and service chases where leak detection, alarming, and interlocks are critical.

Yes. Hallam-ICS engineers integrations between the TGMS, fire alarm, and building management system (BMS). Our toxic gas monitoring experts document a functional cause-and-effect matrix, so each alarm state triggers the correct, testable response across connected systems.

Hallam-ICS TGMS solutions continuously monitor target gases, deliver clear alarms, execute automated responses (tool interlocks, gas shutoff, ventilation changes, door logic), and capture event logs for compliance and root-cause analysis - engineered by the Hallam-ICS Team for your specific hazards.

Based on a hazard analysis and your AHJ’s requirements, Hallam-ICS configures audible/visual alarms, tool purge and shutdown, gas cabinet and VMB shutoffs, BAS and fire alarm notification. The Hallam-ICS Team verifies these sequences during commissioning.

Hallam-ICS toxic gas monitoring experts select sensor technologies and locations using gas properties, airflow, equipment layouts, and serviceability. Alarm setpoints are established using code guidance, exposure limits, and operational considerations to balance safety and nuisance-alarm reduction.

Hallam-ICS provides a structured program with routine inspections, bump tests, periodic full calibrations, challenge testing of interlocks, and consumables replacement (e.g., filters/tape), backed by version-controlled documentation. The Hallam-ICS Team can perform the work or train your staff.

Hallam-ICS designs for change with standardized configuration practices, spare capacity, and modular architectures. Clear tag naming conventions and documentation allow your team to add gases, tools, or new process areas without re-engineering the entire platform.

Absolutely. A qualified TGMS provider, such as Hallam-ICS, can support both greenfield fabs and complex retrofits. For new facilities, Hallam-ICS delivers comprehensive services including front-end studies, basis-of-design, detailed engineering, panel fabrication, integration, factory and site acceptance testing (FAT/SAT), commissioning/startup, and ongoing service. For retrofit projects, our experienced teams plan and execute upgrades on live sites, carefully phasing work to minimize downtime and disruption to operations.

Yes. Hallam-ICS specifies and fabricates UL-compliant panels, including solutions for hazardous locations where required. The Hallam-ICS Team tests, labels, and documents all panels to match your I/O and network standards.

Hallam-ICS delivers P&IDs, I/O lists, alarm response matrices, network architecture, cause-and-effect tables, calibration/maintenance procedures, FAT/SAT protocols and results, and commissioning reports—organized by the Hallam-ICS Team for EHS, facilities, and operations stakeholders.

Yes. Hallam-ICS integrates alarm and trend data with historians or enterprise reporting so you can generate audit-ready reports, analyze nuisance alarms, and drive continuous improvement - supported by Hallam-ICS toxic gas monitoring experts.

OUR TAILORED APPROACH

Whether you are a semiconductor manufacturer, advanced research facility, or a university lab, our tailored approach ensures that our solutions are perfectly aligned with your unique requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.