Our engineers have the space to thrive, the opportunity to hone their expertise, and the time to engineer solutions for problems in the community. These experiences motivate our teams to be the partner you need to understand goals, acknowledge current demands, and anticipate future needs for a new or changing facility, and then develop a sustainable design needed to make the building work specifically for you.

At Hallam-ICS, we design MEP systems that turn end users’ ideas into functional plans for high-performance research facilities, production plants, educational buildings and healthcare campuses. Our MEP engineering experts know your power, cooling, heating, lighting, water, and gas/chemical systems inside and out so you don’t have to.

Replacing a DC motor with an AC motor is not as simple as buying a new

motor with the same horsepower rating and installing it in place of the

old one. For a successful conversion, many details must be addressed.

This whitepaper will examine torque and speed, including constant speed vs. variable speed applications, speed control, and installation consideration. It also discusses the secondary benefits of switching from DC to AC motors.

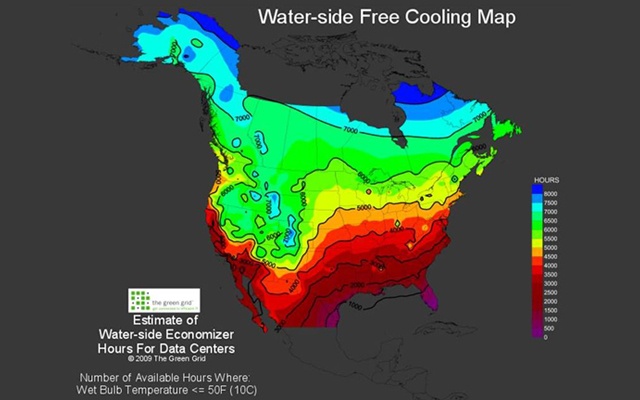

As many people know, running an air conditioner is energy intensive and expensive. The solution to this, that applies to all types of buildings but is magnified by the scale of the data center, is an economizer.

An economizer in the mechanical engineers world is a device or system that takes advantage of environmental conditions to reduce the cooling load on the system. It is often referred to as “free-cooling” because it allows you to turn off the compressors, which are the major energy consumer in a mechanical system.

Fifteen years ago, a co-worker asked me if I would be willing to be a mentor in his place when he had commitments that prevented him from continuing to participate. Not having any previous experience as a mentor, I did not know what to expect. Going to my first day as a mentor, I worked with a group of Architects, Contractors and Engineers that works with inner-city high school students to develop a project from a concept to building a massing model to doing a presentation of the project at the end of a fifteen week program.

- Project Manager, Semiconductor Client

Industrial facilities typically have two kinds of problems – those that hurt profitability, and those that pose a safety risk.

Whether you need to increase production or flexibility, reduce waste or energy consumption, improve safety, or ensure code compliance, our engineers leverage their industrial experience to help solve your problems.

| 363 Main Street, Suite 303, Middletown, CT 06457 |

Tel: 860-788-6815 | Fax: 802-658-1457| 575 West St., Suite 220, Mansfield, MA 02048 |

Tel: 508-821-9759 | Fax: 508-821-9739| 107 Hermes Rd., Suite 210, Malta, NY 12020 |

Tel: 518-289-5582 | Fax: 802-658-1457| 56 Hunter Street, Suite 330, Apex, NC 27502 |

Tel: 919-821-4145 | Fax: 919-821-4147| P. O. Box 350236, Palm Coast, FL 32135 |

Tel: 386-263-8331 | Fax: 919-821-4147| P. O. Box 181686, Dallas, TX 75218 |

Tel: 469-507-9194 | Fax: 919-821-4147| 817 Tradesmens Park Loop, Hutto, TX 78634 |

Tel: 512-759-8009| 38 Eastwood Drive, Suite 200, So. Burlington, VT 05403 |

Tel: 802-658-4891 | Fax: 802-658-1457* In MA, MI, NC, NY, and OH engineering is performed by Hallam Engineering, LLP.

Hallam-ICS Quality Management System complies with the requirements of ISO 9001:2015 for the following scope of certification:

Systems Engineering, Design and Commissioning

Arc Flash Assessments and Electrical Safety Training

Design, Development, and Assembly of Process Controls and Plant Automation Systems

Copyright © 2023 Hallam-ICS All Rights Reserved

The copyright in this website and the material on this website (including without limitation the text, images, and audio-visual material) is owned by Hallam-ICS. No use of any material covered by this copyright may be used in whole or in part without the express written consent of Hallam-ICS.