Clean Utility System Controls Upgrade Turnkey Solution

Implementing a secure, uniform site-wide system for enhanced safety and emergency response.

Challenge

Pfizer invests heavily into research and development to maintain their product pipeline. As new products receive FDA approval, manufacturing facilities need to be adapted. As Pfizer was undergoing a major renovation of existing manufacturing suites to accommodate new products, they required an upgrade of the existing clean utility systems including the Water for Injection (WFI) system along with the Utility Monitoring System (UMS) for clean steam, chilled glycol and chilled water. The control system needed to be upgraded in order to accommodate new equipment designed to increase capacity and Pfizer called upon Hallam-ICS to lead the project.

Solution

Hallam-ICS assembled a multi-disciplined team to complete this turnkey project. The team included a project manager, control system engineers, technicians and subcontractors.

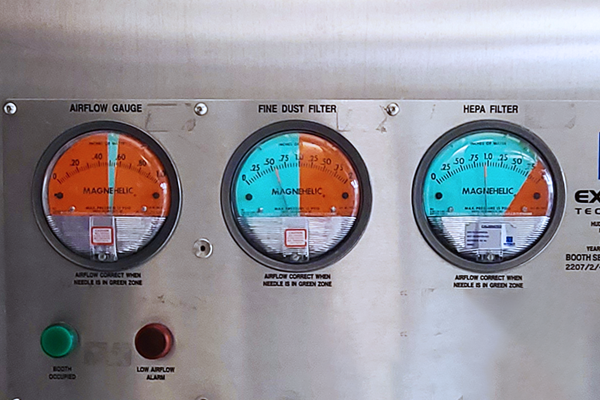

The project consisted of designing, fabricating and programming new PLC-based control panels, modification to the existing SCADA application and IQ/OQ startup testing. The project also included a large Instrumentation package as well as the furnishing of over 60 additional control panels for other portions of the project.

Hallam-ICS utilized the GAMP V-model methodology to perform the project, developing all design documents (URS, FS, SDS and HDS) and commissioning (FAT and SAT) documents and participated in IQ/OQ execution.

The completed WFI system satisfied the required capacity to meet Pfizer’s current and future needs with an improved user interface and completed validation documents.

Results

Our team accomplished the following:

- Enhanced Capacity and Compliance: Delivered a fully upgraded Water for Injection (WFI) and Utility Monitoring System (UMS) to meet Pfizer's current and future manufacturing needs, including validated documents satisfying FDA requirements.

- Comprehensive Turnkey Execution: Managed a multi-disciplinary team to design, fabricate, and program PLC-based control panels, modify SCADA applications, and provide over 60 additional control panels.

- Adherence to Industry Standards: Utilized the GAMP V-model to develop detailed design and commissioning documents, ensuring seamless IQ/OQ execution and project validation.