Fabrication and Characterization Facility

Implementing a secure, uniform site-wide system for enhanced safety and emergency response.

Challenge

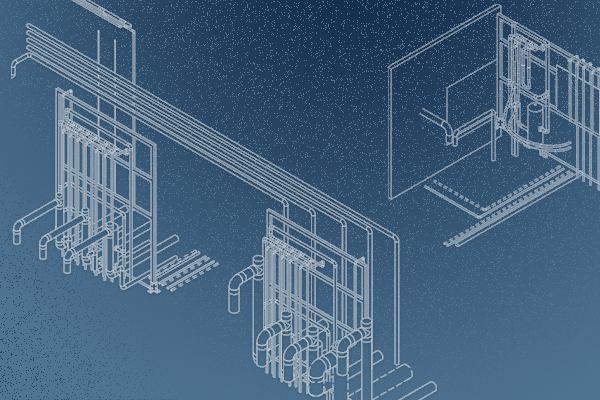

Renovating an existing 20,000 sq. ft building for advanced research in quantum computing required a phased approach to meet evolving needs, including helium recovery, inert gas systems, and high-spec cleanrooms. Ensuring the seamless integration of specialty systems while coordinating with the owner’s engineering teams was crucial to maintain project quality and timelines over a five-year span.

Solution

Hallam-ICS provided comprehensive process engineering for all three phases, addressing complex requirements such as helium recovery, hazardous gas monitoring, and cleanroom design. By collaborating with the owner’s mechanical and electrical engineers, we defined utility needs, commissioned systems, and ensured alignment with future tools and research needs.

Results

Our team accomplished the following:

- Designed and commissioned a 150-liter/hour helium recovery system, enabling efficient resource utilization.

- Delivered specialty gas systems and hazardous monitoring for two high-performance cleanrooms, totaling 4,000 sq. ft.

- Provided utility matrices and system designs to support seamless tool integration and future scalability.