Cleanroom Renovations

We approach our work from a Whole Facility Design Perspective, resulting in elegant, efficient engineering solutions that are practical and reliable, maximizing your long term benefit from your facility.

Challenge

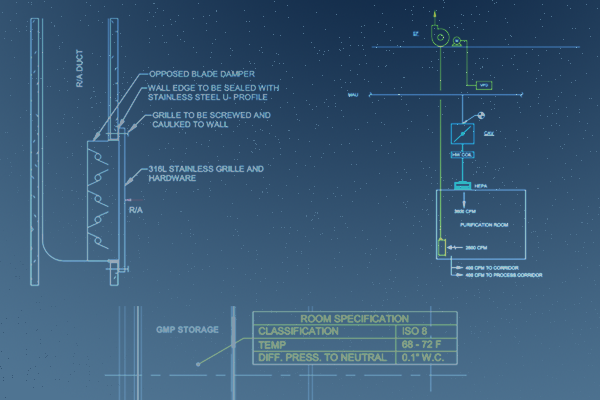

Hallam-ICS was selected to provide MEP and process engineering for the renovation design of ~2,800 GSF of cGMP manufacturing space in an occupied manufacturing facility. The project delivery method was Design Build and the project design schedule was only 40 days from award to IFC.

The design incorporated the following to meet cGMP guidelines:

- Cleanroom HVAC

- Fire Protection

- Plumbing

- Process Piping and Process waste

- Process vessel modifications

- P&ID generation and updating

The Hallam-ICS team approached the fast-paced project with a new client and new architectural partner through consistent and effective communication. A team of two project managers led the effort to make sure that all design team members were up to date and moving in the same direction. All construction administration activity was performed by the same design officials.

Solution

The Hallam-ICS team approached the fast-paced project with a new client and new architectural partner through consistent and effective communication. A team of two project managers led the effort to make sure that all design team members were up to date and moving in the same direction. All construction administration activity was performed by the same design officials.

Results

Our team accomplished the following:

- Delivered a comprehensive cGMP-compliant design within a tight 40-day schedule.

- Successfully integrated complex MEP and process systems into an occupied facility.

- Fostered effective collaboration with new project partners, ensuring alignment and efficiency.