Five Benefits of Completing a 5-Year Arc Flash Update

by Scott King, PMP on Sep 28, 2023 10:30:00 AM

Introduction

You have recently completed your initial arc flash analysis to ensure OSHA and NFPA 70E compliance as well as providing the needed protection for your electricians and maintenance personnel when working on live electrical components. As Plant Managers, EH&S professionals, or electrical engineers, you are quite pleased that your electrical equipment has the necessary labeling identifying the required personal protective equipment (PPE). So, you ask yourself, now what? According to the guideline, I’m good for the next 5 years but why would I have to do another update in 5 years? I had the study done and my equipment is labeled. Therefore, my facility is compliant. Can’t I just leave it at that?

These are great questions which is why I want to share with you five benefits of completing a 5-year update and what it ultimately will mean for you and your facility.

Recap

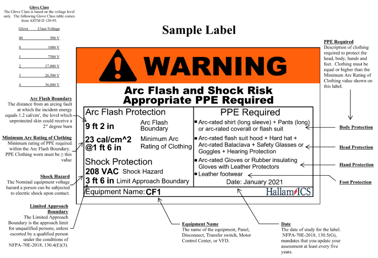

But first, let’s do a quick recap: One of the main reasons of completing these arc flash assessments is to get your facility in compliance with the OSHA mandate to provide electrical safety in the workplace for your personnel. But more importantly, identifying the “incident energy level” at the various pieces of electrical distribution equipment within your facility. Once we know this, we can then identify the proper level of PPE a person needs to wear when performing live energized work on any particular piece of equipment. We determine this based on the NFPA 70E guideline and IEEE 1584.

Let’s Get Into the 5 Benefits

Benefit #1 – Facility Changes

Most facilities experience on-going changes to their electrical distribution systems due to renovations, additions, changed equipment such as a large chiller, manufacturing line changes, and/or simply the removal of equipment. When this happens, the results of the current study may be inaccurate which means the labels are no longer valid..png?width=1419&height=1015&name=combined%20(1).png) If your 5-year update is coming due or even if it’s still a few years out, it would be to your benefit to update the study to reflect the changes of your facility. The nice thing is, the original study has already been completed with the data files and updating the study may not be that big of a deal and you can rest assured that you will get updated labels with current and correct information to properly protect your qualified personnel.

If your 5-year update is coming due or even if it’s still a few years out, it would be to your benefit to update the study to reflect the changes of your facility. The nice thing is, the original study has already been completed with the data files and updating the study may not be that big of a deal and you can rest assured that you will get updated labels with current and correct information to properly protect your qualified personnel.

Benefit #2 – Utility Contribution Changes

Another reason a 5-year update is required is the utility company. They are typically the largest contributor to a fault since they are essentially a very large generating source of available fault current. Utility companies are constantly making infrastructure changes to their system. They may change upstream transformer sources (KVA, impedance values), overcurrent protection changes (primary fusing/cutouts), transmission distribution feeder changes and distances. When this happens, the three phase and single phase to ground available fault current values change entering your facility. This most definitely will change the calculations of incident energy resulting in inaccurate labels on the equipment which means the level of PPE may not be adequate for your qualified personnel. It’s in your best interest to update the study.

Another reason a 5-year update is required is the utility company. They are typically the largest contributor to a fault since they are essentially a very large generating source of available fault current. Utility companies are constantly making infrastructure changes to their system. They may change upstream transformer sources (KVA, impedance values), overcurrent protection changes (primary fusing/cutouts), transmission distribution feeder changes and distances. When this happens, the three phase and single phase to ground available fault current values change entering your facility. This most definitely will change the calculations of incident energy resulting in inaccurate labels on the equipment which means the level of PPE may not be adequate for your qualified personnel. It’s in your best interest to update the study.

Benefit #3 – NFPA 70E/IEEE 1584 Changes

NFPA 70E is guaranteed to change every 3 years and the current version we are now using is the 2021 version. The next version will be coming out either in late 2023 or early 2024. The guideline changes every 3 years because “things” change; we learn about new accidents and how it impacts the current version which may result in narrative changes to certain sections.

For example, depending on what the steering committee of 70E learns from the incidents or accidents, it could change how the guideline designates personal protective equipment (PPE) based on certain levels of “incident energy”. Lockout/Tagout procedures could change or electrical safety program requirements. It could affect how to establish a “risk assessment, controlling risk and monitoring risk” and “limits of approach” to equipment. And most importantly, the incident energy and arc flash boundary calculation methods could change which is related to IEEE 1584. IEEE 1584 is much different than NFPA 70E when it comes to changes. We most recently had an IEEE 1584 change in 2018 but prior to that, the last change was in 2002 (a 16-year gap).

With all these changes it may be beneficial to update your study and labels with the most current information to ensure your qualified personnel are properly trained and have updated labels identifying incident energy levels, arc flash boundary, and proper PPE.  Although, you can wait until you hit the 5-year mark. A rule of thumb I tell my clients, if there are substantial changes either to NFPA 70E or IEEE 1584, I would recommend to them that they do an update sooner than later. The recent IEEE 1584 – 2018 changes were quite comprehensive regarding the formulas and calculation method. This would warrant an update so that personnel are properly protected.

Although, you can wait until you hit the 5-year mark. A rule of thumb I tell my clients, if there are substantial changes either to NFPA 70E or IEEE 1584, I would recommend to them that they do an update sooner than later. The recent IEEE 1584 – 2018 changes were quite comprehensive regarding the formulas and calculation method. This would warrant an update so that personnel are properly protected.

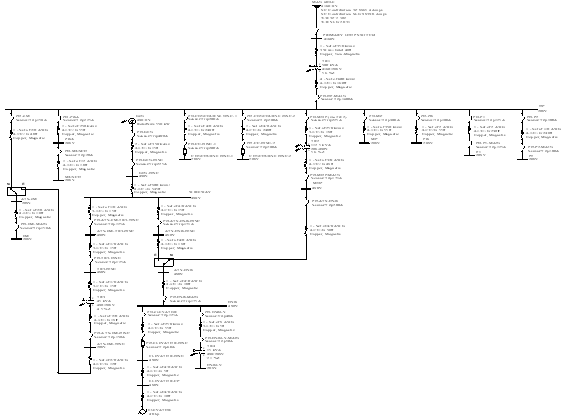

Benefit #4 – You Get Updated One-Line Diagrams

Most people don’t realize that when you do an “engineered” arc flash analysis, part of the deliverable includes updated one-line diagrams of your facility. This is essentially an electrical “road map” of the building. This information is invaluable to your facilities electrician and maintenance staff. The one-line fundamentally identifies how the building is wired starting from the outside utility transformer(s), to the main switchgear, all the way down to the interior panel boards, motor control centers, busducts, control panels, large HVAC equipment, step down transformers, etc. The information can be used to troubleshoot problems, understand how certain pieces of equipment are wired, identify potentially overloaded equipment, and areas for improvement. An accurate one-line diagram is extremely beneficial.

Sample One-Line Diagram

Benefit #5 – Peace of Mind

I use this benefit as the “last line of defense” because if you’re responsible for the safety of your employees as the Environmental and Safety Manager or the Plant Manager, I’m sure you want to make sure that the people who work on live exposed electrical components are properly clothed and protected from an arc flash and/or shock hazard. And, to have them be properly trained by attending a Low Voltage Qualified Electrical Training course. I don’t have enough fingers on my two hands to count the number of times someone called me because one of their personnel experienced an arc flash event and either got seriously burned and, in some cases, death resulted. These are very difficult calls to take because if their personnel were properly trained to understand the hazards and if the building had the arc flash assessment, these accidents could have been avoided.

My team and I have an enormous amount of passion helping our customers become compliant and educating them to understand how serious this can be. On average in the US, every other day, someone is killed either by electrocution or killed by serious 3rd and 4th degree burns to more than 75% of their bodies. I hope this information has been helpful and you find these 5 benefits worthwhile when it comes to completing your 5-year arc flash update.

About the Author

Scott has retired from Hallam-ICS, but his contributions to the company continue to be valued.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina Texas and Florida and our projects take us world-wide.You May Also Like

These Related Stories

How to Develop a Budget for Arc Flash Compliance

Inspired Engineering – Things I learned in My First Hallam Year

No Comments Yet

Let us know what you think