How to Develop a Budget for Arc Flash Compliance

by Jason Mazzola on Aug 11, 2022 10:30:00 AM

By prioritizing and scheduling your Arc Flash Study over 5 years you can manage the cost and time investment while keeping your facilities safe and in compliance with NFPA 70E.

Arc Flash compliance, as I am sure you are aware, is a very important component at any work location. This includes providing equipment labeling that indicates the incident energy at a given piece of equipment. Labeling is a vital component to ensuring that your staff is properly protected from the hazard they may be introduced to. One of the best ways to insure this is to have an Arc Flash Study conducted at your location. The financial burden of noncompliance can be millions of dollars once you factor in fines, medical treatment cost and any other monetary amounts incurred during litigation. More import than the financial implication is the potential for loss of life to a worker because of an event.

With the cost of everything going up companies are looking for ways to save money and safety should not be one of those areas. Budgeting for an Arc Flash Study can be hard because the cost to have one completed can be an unknown until you bring a firm in to give you a quote. If you are a multi-site or even global company the cost may be too much to budget for one year. Luckily there is a good solution to this problem, and it is something we have helped many clients with. Let’s look at an example of what this might look like for your facility.

Sample Budget Planning

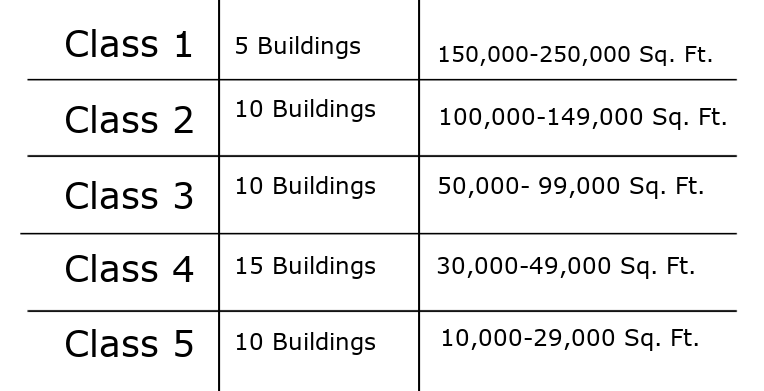

One of our larger clients has 50 buildings that need to be brought into compliance. Looking at the cost to do all 50 sites in one year would be a substantial undertaking. I will use some ballpark figures for this example, but I think it will paint a pretty good picture. Let’s assume that the 50 sites are made up of a combination of manufacturing, storage, and office space. The buildings are of various sizes and the breakdown is below. I will refer to them as classes to be used as reference later.

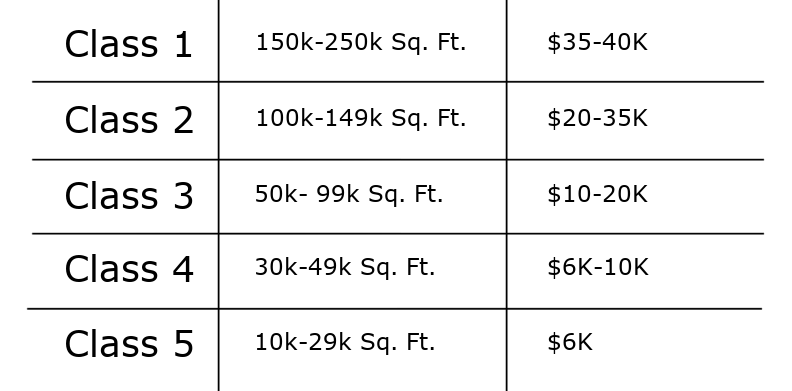

Average Cost by Class

Using our sample client above with 50 buildings, the total cost of the project could range from $625,000 on the low end to $960,000 on the high end depending on what the actual composition of the builds are. These are obviously very large dollar amounts to consider and most moderately sized businesses maybe can’t absorb the expense in a single fiscal year. The best approach that we have found is looking long term over 3-5 years.

5 Year Plan

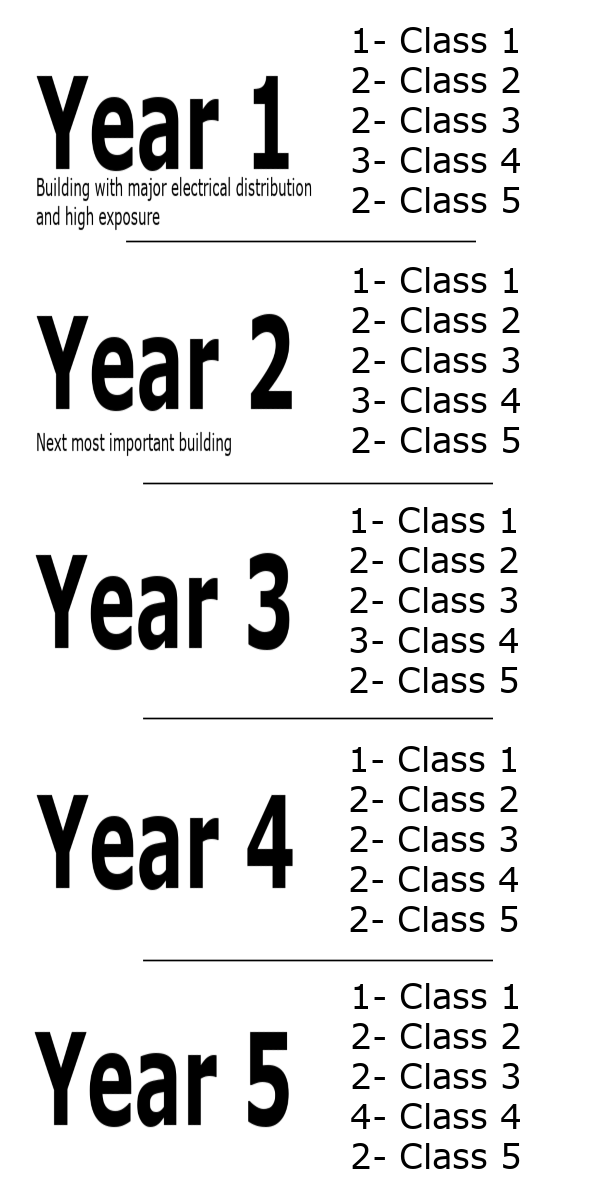

For this example, let’s look at a 5-year plan to bring the sites into total compliance. Some general consideration you may want to make while evaluating what buildings need to be done first are, where is the most exposure and what locations have the most interaction with live parts. A good starting point is the facilities with large electrical distribution centers.

The 5-year plan offers additional benefits above and beyond the more manageable cost and budgeting allocations. Considering that the requirement in NFA70E is to have the study updated every 5 years going with this model sets up the ability to budget long term to stay in compliance. It is important to note that the cost to have a study updated should be significantly lower than the original from scratch study. If any major modification to the system is conducted prior to the update date it is a good idea to contact the firm who did the original study and have them reevaluate the system to see if any incident energy levels have changed. This is something we do for many of our clients and is recommended in the NFPA70E standard.

Looking at the theoretical breakdown of a 5-year plan it might look something like this.

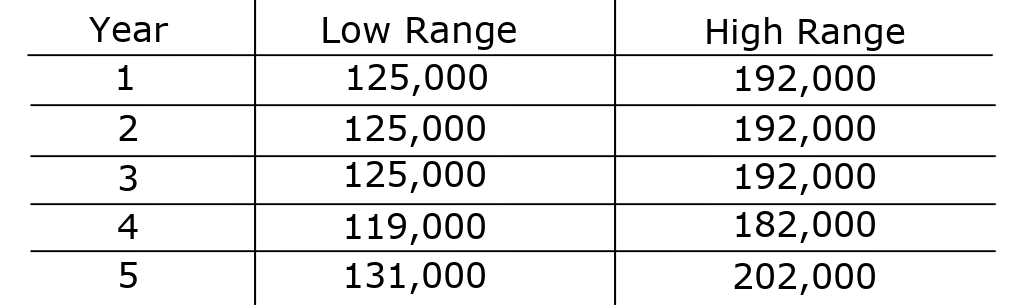

Based on this 5-year schedule, the annual cost breakdown would look something like this:

Based on this 5-year schedule, the annual cost breakdown would look something like this:

Now I know that these are still large amounts to budget for but considering that around 10 buildings would be done each year the cost isn’t that bad on a per building basis. Keep in mind that this is just a theoretical example of a larger company with many sites. This same principle can be applied to small companies with fewer buildings. This method sets you up for the five-year update cycle and makes budgeting much easier. Like I mentioned, the cost to do an update should be substantially less than these original costs so you should be able to plan for these costs to go down on the next go round. In my opinion this method also shows that as a company you are doing your due diligence and trying to get your system into compliance if anything should happen before all buildings are completed. That is not to say you will not endure financial expenses as a result, but the fines may be lessened.

If you have any questions or would like to discuss planning and budgeting to get your sites into compliance, please reach out to us at Hallam-ICS for a no cost consultation. Our dedicated team of Arc Flash Engineers can help you put a plan into action and help you come up with some budgetary figures to present to your decision-making board.

In my next Blog I will discuss the benefit of standardizing your Arc Flash approach across all facilities so please check back soon for that Blog.

I can be reached at JMazzola@Hallam-ICS.com

About the author

Jason Mazzola is the Director of Electrical Safety Services for Southern New England out of our Mansfield, MA office. He joined Hallam-ICS in 2019 and prior to that spent 10 years in utility industry in various engineering and leadership roles.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Five Benefits of Completing a 5-Year Arc Flash Update

The Wrong Time to Find Out Your Arc Flash Study is Outdated…

No Comments Yet

Let us know what you think