Hazardous Gas Monitoring: Key Elements of a Safety Requirement Specification

by Jim Blais on May 2, 2019 10:31:00 AM

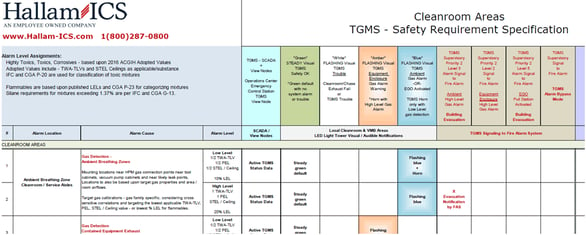

Developing a Safety Requirement Specification (SRS) or functional “cause & effect” matrix for a Hazardous Gas Monitoring System is absolutely critical to identify and then eliminate potential gas related hazards. The approved SRS purpose is to provide people, equipment and the facility with safety and freedom from unacceptable risks.

Development of an SRS requires participation of cross-functional disciplines (EH&S, Facilities and FAB Engineers and Management). The approved SRS becomes the basis of design for the Hazardous Gas Monitoring System. Depending upon the acceptable risk, the required reliability of the Hazardous Gas Monitoring safety system can be further ensured by understanding and providing effective measures of:

- failure avoidance,

- failure detection, and

- failure tolerance

This reliability applies to all of the hazardous gas monitoring safety sensors, the logic controller and the required final control elements (gas shutdown / alarm/fault notifications).

The required reliability is to keep the “probability of failure” as low as possible (failure avoidance), or to detect failures by diagnostic functions (failure detection) and – in the case of a detected failure – to force the safety system to go into a safe state (failure tolerance).

Therefore the SRS should identify:

- Each potential hazard and its consequences

- Definition of the process safe state

- Description of all safety functions

- Description of each alarm level trip point and associated measurement values

- Maximum response time requirements

- Manual safety activation of the safety functions

- Safety function responses to diagnostic faults (shutdown/interlocks, alarm only, or other)

- Local alarm / trouble – notifications (visual and audible)

- Local alarm / trouble – HMI visualization (access and content)

- Remote “Emergency Responder” alarm / trouble – notifications (paging, texting, email)

- Remote “Emergency Control Station” alarm / trouble – HMI visualization (access and content)

- Include maintenance override capability requirements

- Provide system alarming bypass capability requirements

- Requirements for reset or alarm recovery

Common Issues with an SRS

A poor safety requirements specification is the root cause of 44% of safety system problems. The largest single cause being that the needed functionality is missing or incorrect. EPA and OSHA findings of recent accidents find that common themes include:

- Inadequate hazard review or process hazard analysis

- Use of inappropriate or poorly designed equipment – better performance was required.

There may be hazardous gas detection challenges that are not always addressed by minimum code compliance. There are potential gas target cross sensitivities and interference between different gas target sensors and detection technologies. These may suppress sensor response or cancel sensor response by driving the sensor response negative, depending upon the gas leak origin and type, or even poisoning a sensor element and making it unresponsive.

Establishing Hazardous Gas Alarm Levels

Setting SRS hazardous gas alarm levels for individual gas targets should also not focus and apply the mandatory (minimum) code requirements (e.g., OSHA PELs), but consider those authoritative requirements and best practices adopted by others. An example includes:

- The ACGIH® - American Conference of Governmental Industrial Hygienists is a scientific association that develops recommendations or guidelines to assist in the control of occupational health hazards. TLVs® and BEIs® are health-based values and are not intended to be used as legal standards. Threshold Limit Values (TLVs®) refer to airborne concentrations of chemical substances and represent conditions under which it is believed that nearly all workers may be repeatedly exposed, day after day, over a working lifetime, without adverse effects.

- The ACGIH® TLVs® are widely recognized as authoritative, and are required to be included on safety data sheets by the OSHA Hazard Communication Standard.

NOTE – OSHA recognizes that many of its permissible exposure limits (PELs) are outdated and inadequate for ensuring protection of worker health. Industrial experience, new developments in technology and scientific data clearly indicate that in many instances these adopted limits are not sufficiently protective of worker health.

This has been demonstrated by the reduction in allowable exposure limits recommended by many technical, professional, industrial, and government organizations, both inside and outside the United States. To provide employers, workers, and other interested parties with a list of alternate occupational exposure limits that may serve to better protect workers, OSHA has annotated the existing Z-Tables with other selected occupational exposure limits. OSHA has chosen to present a side-by-side table with the NIOSH Recommended Exposure Limits (RELs) and the ACGIH® TLVs®s.

OSHA’s mandatory PELs in the Z-Tables remain in effect.

However, OSHA recommends that employers consider using the alternative occupational exposure limits because the Agency believes that exposures above some of these alternative occupational exposure limits may be hazardous to workers, even when the exposure levels are in compliance with the relevant PELs.

Benefits of a Safety Requirement Specification and periodic testing

- The SRS provides the Owner with a functional specification that records all monitored hazards, their locations, alarm set-points and the actions taken when predetermined limits are exceeded.

- The SRS can be provided to and reviewed with the local AHJ to address any concerns during the design phase.

- Used as a validation/commissioning test document to record system performance during startup, it also becomes a “living record document” that can be used as an auditable record of periodic testing records, required throughout the life of the safety system.

NOTE - “periodic functional testing” of each gas sensor (recorded with the SRS) is highly recommended and required given that many gas sensors utilize “consumable sensors” and the probability of sensor failure therefore continuously rises with operational time. Periodic testing effectively “resets” the probability of the sensor and control platform to “not” perform the required safety functions back to zero.

If you would like more information on SRS for Toxic Gas Monitoring you can contact our

About the Author:

Jim has retired from Hallam-ICS, but his contributions to the company continue to be valued.

Read My Hallam Story

About Hallam-ICS:

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Basic Hazardous Gas Monitoring: Assessment and Selection of Ideal Gas Monitoring Technologies

Harmonizing Hazardous Gas Monitoring Code Requirements and Best Practices

No Comments Yet

Let us know what you think