Laboratory Compressed Gas Safety: Six Design Considerations for Architects and Owners

by Aaron Eicoff on Sep 7, 2021 10:30:00 AM

While engineers help mitigate risks with system design, there are considerations architects and owners should be aware of for the purposes of safety and reduced liability. If you are designing a laboratory with compressed gases, read on to learn a few “common sense” laboratory design items you may have been overlooking!

What is compressed gas and what are the dangers?

A compressed gas is defined by the Department of Transportation as “any material or mixture which exerts in the packaging an absolute pressure of 280 kPa (40.6 psia) or greater at 20°C (68°F)” [49CFR]. Common hazards related to compressed gases in the laboratory include flammability, toxicity, oxygen displacement, and low-boiling-point – among others.

#1 Storage

The most basic design consideration is properly securing the gas containers. Cylinders must always be secured above the midpoint of the bottle – preferably 2/3 of the way up the bottle and second strap 1/3 of the way up the bottle. All gas cylinders should be individually secured. This avoids the potentially catastrophic issue of a single securement breaking free and having all sorts of different chemicals being released into the laboratory simultaneously. It also avoids the more mundane, but dangerous, chance of crushed toe if an un-involved cylinder gets disrupted during a gas change.

#2 Wall Space

Wall space is always at a premium. As an alternative to taking up significant amounts, you can use a gas cylinder rack as seen here.

They are available starting at modest prices of about $1,000. Designs vary regarding footprint and access. Make sure to save some space for a Safety Data Sheet (SDS, formerly known as MSDS) binder holder!.jpg?width=400&name=Rack%20System%20(1).jpg)

#3 Appurtenances

Most people remember the emergency eyewash and shower locations, but how about emergency escape breathing devices (EEBDs) in the vicinity of toxic and “highly toxic” gases? Also consider a dedicated storage for fire blankets, if flammable or pyrophoric gases are present, and first aid kits in the same area.

#4 Signage

Long-term safety of occupants is critical. Consider posting signage related to design decisions such as: separate storage locations for flammables and oxidizers, low exhaust ventilation areas for oxygen displacement storage areas, or general reminders such as to reject and immediately remove any cylinders without proper labeling. Consider all risks for all gases present in the laboratory.

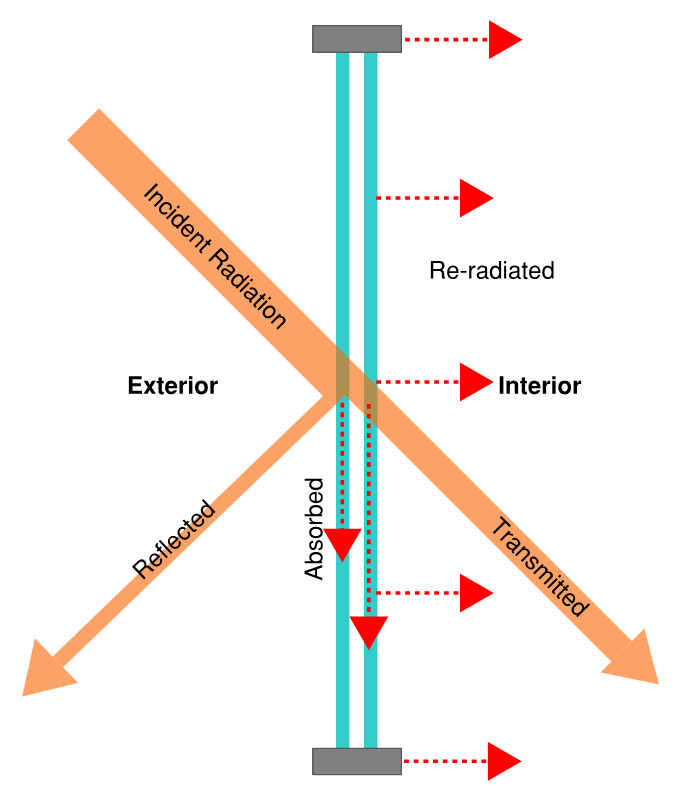

#5 Fenestrations

Another point of consideration that can be ‘over-looked’ are fenestrations. Just as solar heat gain can warm occupants in a conference room, so too can it heat up gas cylinders! Therefore, avoid putting gas cylinders across from windows – especially south-east to south-west facing walls where beam radiation is most powerful. If unavoidable in this placement, the solution of using opaque window treatment exists. The cost of such treatments may qualify for energy rebates in some areas due to their inherent help of reducing summer heating loads.

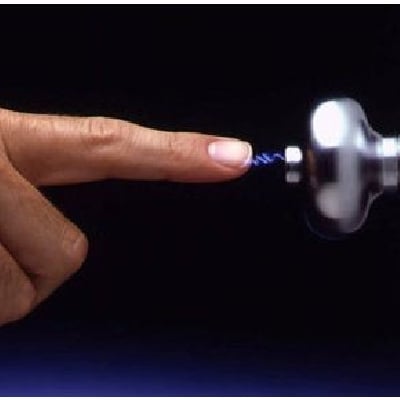

#6 Spatial Relation to MEP Services

Think you can run your lab vacuum and emergency tempered water systems right near your gas cylinders? Think again! Any ferrous metals such as copper or steel should not be run next to gas cylinders. Neither should metallic electrical conduit, but solutions exist. PVC-coated rigid metal conduit is the best answer for these applications at it maintains the strength and safety of metallic without the risk of spark. Equally, some mechanical and plumbing services can be run in non-metallic pipe or tube for short runs at a small premium in cost. For areas containing any flammable gas containers, Class 1 Division 2 lighting should be considered at the price tag of a few $100 per fixture.

Conclusion

Designing a safe laboratory is a collaborative effort which includes the owner, the architect, and the engineer. Secure storage with appropriate signage is the first step. Designing with relation to windows, doors, and other equipment are important considerations. Finally, having emergency equipment properly stored in a convenient location is the last bit of insurance should the worst occur. Ensure you check off all the boxes in safe lab design by involving engineers who know the ins and outs of compressed gas hazards – such as the team of engineers at Hallam-ICS.

About the Author

Aaron has left Hallam-ICS to pursue other endeavors, but his contributions to the company continue to be valued.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Vermont Service Day 2024 – Vermont Youth Conservation Corps

Impacts of Working for a Safety Conscious Company

No Comments Yet

Let us know what you think