What is a Dust Hazard Analysis (DHA)?

by Chris Giusto on Jul 11, 2024 10:33:00 AM

In my last blog I discussed Combustible Dust Fundamentals and NFPA 652 and explained some of the background as to why NFPA 652 requires a Dust Hazard Analysis.

Blogs posts within this series:

- Combustible Dust Fundamentals and NFPA 652

- What is a Dust Hazard Analysis (DHA)?

- A Practical Guide to 5 Important Properties of Combustible Dust

- 7 Steps to Complete a Dust Hazard Analysis

- I've Completed My DHA, Now What?

- NFPA 652 on a Budget-5 Ways to Minimize the Cost of Compliance

This blog will explain what a DHA is, and answer some other common questions about them.

What is a DHA?

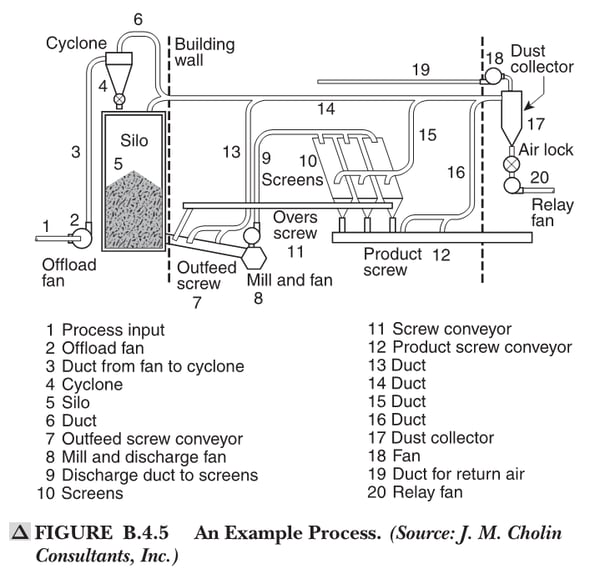

A Dust Hazard Analysis (DHA) is a systematic review of the processes and areas of your facility where combustible particulate solids are present. (Figure B.4.5 below from NFPA 652 shows how an example process is broken down into individual points to be evaluated.) The analysis will help identify the fire, flash-fire, and explosion hazards that exist in your facility. The DHA will categorize locations into one of three general categories: Not a hazard, Might be a hazard, or Deflagration (or Fire, or Flash-Fire) hazard. Locations that fall into the second category will often require additional information or analysis to determine if a hazard exists or not. For each hazard identified, safe operating ranges must be defined as well as any existing hazard management measures and a list of additional hazard management options for consideration.

The goal of your DHA is to identify all the hazards in your facility–especially the ones you did not even know existed. For example, the well-known Port Wentworth, Georgia Imperial Sugar Refinery explosion in 2008 was the result of unknown hazards. A conveyor enclosure created the necessary confinement for dust that was leaking and dispersed from silo outlets, and an overheated bearing inside the enclosure is believed to have been the ignition source. This initial explosion ignited several secondary explosions that had plenty of fuel due to fugitive dust accumulation and poor housekeeping. A DHA likely would have identified these hazards so they could have been addressed. (For a detailed discussion of this incident, you can listen to Episode 3 of the Dust Safety Science Podcast with Dr. Chris Cloney.) A Dust Hazard Analysis is typically conducted as part of comprehensive combustible dust safety services to help facilities identify hazards, reduce risk, and comply with NFPA standards.

Aftermath of the Imperial Sugar Refinery explosion (image form CSB.gov)

When is a DHA Required?

The short answer is always. The requirement to conduct a DHA applies retroactively to existing facilities and processes, and NFPA 652 also requires a DHA for all new processes and facilities.

Who Performs a DHA?

This question does not have as simple an answer the one above. NFPA 652, Section 7.2.2 states:

The DHA shall be performed or led by a qualified person.

The Explanatory Material in Annex A (not enforceable, but provided for clarification) elaborates:

The qualified person who is leading or performing the DHA should be familiar with conducting a DHA. The qualified person should also be familiar with the hazards of combustible dusts. Typically, a team performs a DHA. For some processes this team might be as little as two persons, or for larger and more complex processes, the team might require many more than two persons. This team is made of a variety of persons whose background and expertise can include the following:

(1) Familiarity with the process

(2) Operations and maintenance

(3) Process equipment

(4) Safety systems

(5) History of operation

(6) The properties of the material

(7) Emergency procedures

The individuals involved in the DHA could include facility operators, engineers, owners, equipment manufacturers, or consultants.

While NFPA 652 does not explicitly define who is a ‘qualified person’, it does provide good guidelines for facility owners to consider when choosing a consultant/facilitator or assembling a DHA team. It is possible that you have internal staff who are qualified and capable of conducting a DHA for your facility, but do not discount the value of an outside perspective. A fresh set of eyes may identify hazards your staff could overlook, and someone who has performed DHAs in other industries can also provide valuable insights that apply to your facility and processes. Many organizations choose to work with specialists who provide combustible dust safety services, bringing experience across industries and NFPA-compliant processes.

Compliance Deadline for DHAs

NFPA 652 required owners to conduct a DHA for existing facilities and processes by September 7, 2020. However, this is a situation where it truly is “better late than never.” Conducting a DHAs will not only keep you compliant, but also shows your employees that you are dedicated to their safety and serious about minimizing hazards in their workplace.

Summary

A DHA is a systematic review of the processes and areas of your facility where combustible dusts are present. The deadline for existing facilities to complete a DHA has come and gone. And finally, if you haven’t gotten started, now is the time - this process can save lives.

If you have questions or would like more information about DHAs and Combustible Dust Safety, you can contact Chris directly via email at cgiusto@Hallam-ICS.com.

About the Author

Chris Giusto is Regional Manager for the South Atlantic and Director of Combustible Dust Safety at Hallam-ICS. He works with clients to improve processes & safety, reduce waste & energy consumption, increase flexibility & capacity, and build new facilities. He has over 20 years of engineering experience and leads Hallam’s Combustible Dust Safety Service offerings. He’s spent nearly his entire career working with combustible dust hazards and designing NFPA-compliant equipment and systems. With additional expertise in material handling and dust collection system design, he and his team bring a comprehensive approach to practical solutions for improving safety and meeting NFPA requirements.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina, Texas and Florida and our projects take us world-wide.

You May Also Like

These Related Stories

A Practical Guide to 5 Important Properties of Combustible Dusts

7 Steps to Complete a Dust Hazard Analysis (DHA)

Comments (4)