Power System Arc Flash

Augusta Health

Fishersville, VA

Ensure reliability of electrical power distribution systems for compliance with OSHA and NFPA 70E Electrical Safety in the Workplace guidelines.

Challenge

Augusta Health is among the finest community hospitals in America. Located in Fishersville VA, Augusta Health opened in 1994 to continue a tradition of personalized care with small-town hospitality that began more than 50 years ago with predecessor hospitals in Staunton and Waynesboro, Virginia. Today, their highly trained physicians and staff use state-of-the-art technology to provide superlative care with warmth and compassion.

When choosing Hallam-ICS to complete a power system study, Augusta Health shared what was most important to them: “to ensure reliability of their electrical power distribution systems for compliance with OSHA and NFPA 70E Electrical Safety in the Workplace guidelines.” This became everything to Hallam-ICS.

Solution

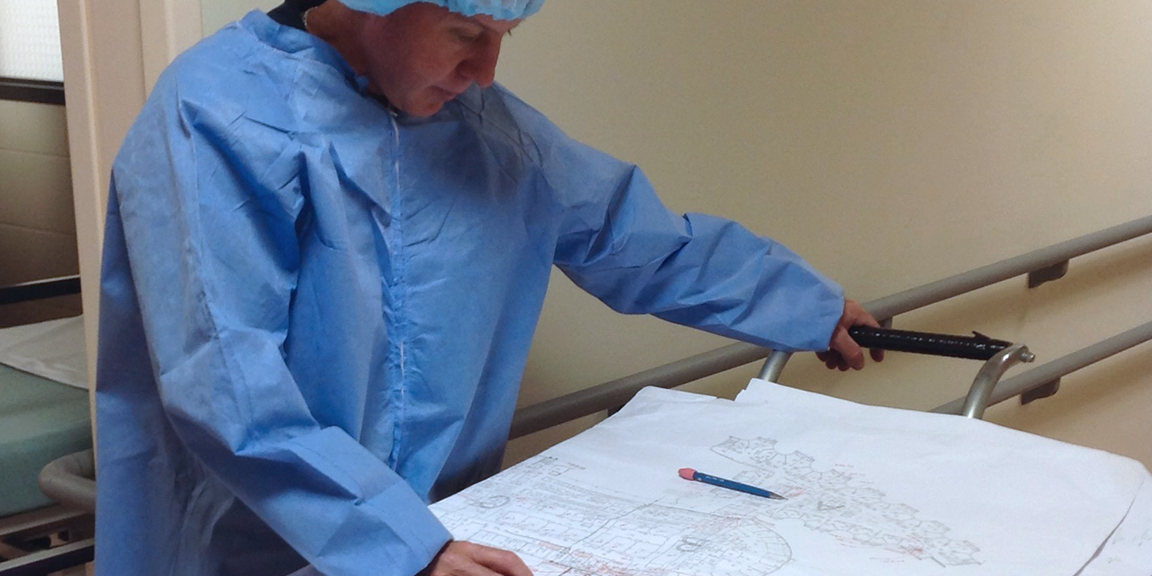

Knowing that it is critical that the electrical systems remain operational 24 hours a day, 365 days a year, Hallam-ICS recommended a 100% survey of all electrical equipment, including: normal power, emergency life safety and critical systems so as to complete a short circuit, coordination and Arc Flash Analysis. With safety being the number priority, Augusta Health knew that there would be certain events that would require their qualified personnel to perform live work on their electrical systems since de-energizing is not option in this type of environment.

Hallam-ICS was able to document the entire electrical distribution systems so as to develop an up to date electrical one-line diagram of the entire facility. In addition, photographs and updated panel schedules were developed for all electrical equipment and included within the study. As the survey was completed, Hallam-ICS documented the locations of all equipment and provided updated floor plans for their use.

When completed, we were able to analyze the incident energy levels and provide recommendations to lower the levels when applicable. Recommendations were also provided to ensure proper coordination of systems so in the event of a failure or faulted situation, the device in question would clear the fault and not shutdown major portions of the facility. When we finished, we provided compliant labels on all equipment identifying the incident energy hazard and proper protective clothing required by qualified personnel when working on live exposed electrical components.

Results

Our team accomplished the following:

- Enhanced Safety Compliance: Completed a comprehensive Arc Flash Analysis and provided compliant labels for all equipment, supporting OSHA and NFPA 70E guidelines and ensuring safe work practices for qualified personnel.

- Reliable Power Distribution: Improved system coordination to prevent unnecessary shutdowns, ensuring critical and life-safety systems remain operational.

- Detailed System Documentation: Developed updated one-line diagrams, panel schedules, and floor plans, creating a thorough reference for maintenance and emergency response.