Key Factors to Consider when Sizing a Generator

by Dan Zang on Aug 31, 2023 10:30:00 AM

“We Have Plenty Of Capacity On Our Generator.”

I generally hear this phrase when I first arrive at a project site that requires more generator powered equipment.This phrase is generally followed up with, “We took amperage (current) readings just the other day. The readings are below the generator rating”.

In the Beginning

Generators are often part of the initial building design and sized for the generator loads that are required at construction. In some instances, a generator might be sized for future capacity but generally this is not the case due to budget constraints.

As time goes on, other loads are generally added. A phrase I like to use is, “A generator is like a magnet; once someone knows a building has one, their equipment must be powered by it”.

In many cases generator load increases over time but available capacity isn’t checked properly.

Why is Checking Generator Capacity with Software Important?

Taking amperage measurements is valuable information to have but it doesn’t address the most critical item when sizing a generator.

Generator starting current, often expressed as SKVA or SKW, almost always determines the size of, or the capacity of a generator.

What is Starting Current?

In simple terms, it’s the initial power required to start motor rotation or initially energize electrical coils in transformers. Starting current can be significantly higher than running current. Generally, after a few seconds, when motors are up to speed, the starting current reduces and running current is established. Running current is what people generally measure in the field.

I occasionally use this analogy: “Assume you are trying to push a car on level ground. It takes a large amount of effort to get the car to move, much like starting current. Once the car is in motion, it’s much easier to push, like running current”. A generator is required to be sized for starting current.

How Do You Reduce Starting Current?

If excessive starting current is an issue, the goal is to reduce the quantity of equipment starting at once and to reduce the spike of current during motor starting.

Motor Controllers

The type of motor controller, often referred to as motor starter, has a big effect on motor starting current.

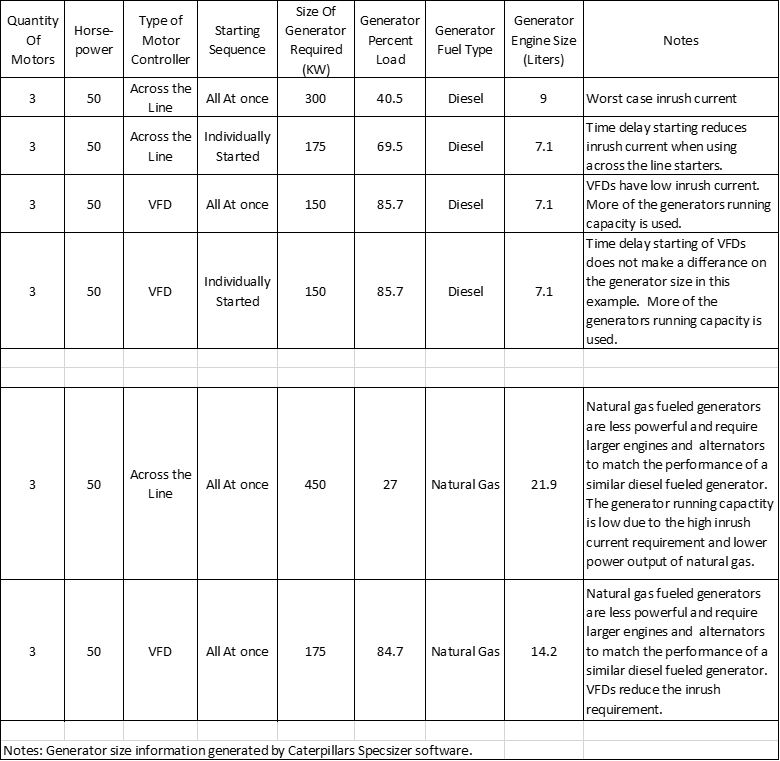

An across the line starter applies full power to a motor instantly. This causes a spike in power that the generator must overcome. A VFD (variable frequency drive) starts a motor slowly over time. This minimizes the starting current and can reduce the generator requirements.

Below is a table that demonstrates how the same size motor using a different motor controller can affect the generator size required.

Time Delay Starting

Often, generator loads are on one system and start all at once. A method to reduce starting current is to stagger the starting of the motors. The use of time delayed motor starting lowers the instantaneous peak current and spreads it out over time.

UPS’s (uninterruptible power supplies)

A UPS is a battery backup system that is generally used for critical loads such as a data center. UPS’s are often used to bridge the gap from when utility power has failed to when a generator has started, stabilized and able to take on load.

It can be challenging to accurately capture the load that a UPS will have on a generator.

UPS Battery Recharge

A common misunderstanding is that a UPS load is just the rating of the UPS. Due to the UPS battery system, a battery recharge rate has to be added to the UPS rating to obtain the total anticipated generator load. This added load can vary by manufacturer and product. Battery recharge rates of 10 to 25 percent over the UPS rating are common.

This added increase in load can easily be missed when taking random power measurements.

Redundant UPS Systems for Data Centers

Often a data center will have two redundant power systems. Each electrical system will generally have a UPS that furnishes power to data racks.

Large computing data racks are generally equipped with power distribution units. (PDUs). Some PDU’s will provide power to a rack evenly. If one power source is to fail, all the power is then provided by the one remaining power source. This is great for power redundancy at the data rack but essentially doubles the power on the one remaining power supply. A UPS on the one remaining power supply also will have a load increase.

This possibility of an added load due to a failure of a system can easily be missed when taking random power measurements.

Other Generator Related Items To Be Aware Of

There are many code requirements that relate to equipment placed on a generator system. Often only fire alarm, emergency, and exit lighting come to mind. This isn’t always the case. As an example, in a semi-conductor or pharmaceutical facility, there are many other codes that have generator power requirements.

Transfer switches are used to distribute normal or utility power and generator power.

Transfer switches are classified by categories within the National Electrical Code (NEC). The NEC has specific time intervals for generator backup power to be available per classification. The proper segregation of the load classifications on a transfer switch is required by NEC.

Another item we encounter is equipment that must operate in pairs to function properly. As an example, an exhaust fan on a generator will likely require a makeup air unit to also be on the generator. This ensures that the exhaust fan has makeup air (or supply air) during a power outage.

Electrical harmonic issues from older VFDs and UPSs can also affect generator sizing.

What Hallam-ICS Can Provide

At Hallam-ICS, we review a client’s generator system as a whole. We review:

- What the generator furnishes power to.

- Depending on the building type, and what is required to be on generator power by code.

- Are there UPS’s on the system? Is there a data center ? What type of PDU’s are used ?

- Are there old VFDs and or UPSs that cause harmonics resulting in generator capacity issues ?

- Equipment that needs to operate in “pairs” on the generator system.

- Are the loads on the generator transfer switch properly segregated per NEC ?

- Hallam-ICS uses generator sizing software to determine the size and other generator requirements. The software assists with:

- Determining the starting current of the load on the generator.

- If the generator analysis results in high starting current, are time delays a suitable option to reduce starting current ?

- Are VFD’s an option to reduce starting current ?

Let Us Know If We Can Help

Have any questions, let us know. Our team will work with you to understand your goals, current demands, and anticipate future needs for a new or changing facility. We will develop a sustainable plan to work specifically for you.

About the Author

Dan has retired from Hallam-ICS, but his contributions to the company continue to be valued.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina , Texas and Florida and our projects take us world-wide.

You May Also Like

These Related Stories

Advancing Automation Technology - How to Specify a Domain Controller

Spill Control & Secondary Containment: Code Basics & Solutions

No Comments Yet

Let us know what you think