The 2021 NFPA 70E Changes are Coming! 5 Major Changes You Need to be Aware of (Part 4 – Article 130)

by Scott King, PMP on Nov 19, 2020 10:30:00 AM

Another 3 years has passed and it’s time for another NFPA 70E update. This new update will be the 2021 version. This document will provide a brief summary of the proposed changes. Please note that these changes have not yet been fully adopted, but they provide a fair representation of what’s likely going to be in the final version.

I was fortunate to get a sneak preview to the proposed changes by attending a webinar in July 2020 hosted by Jim Phillips of brainfiller. Jim is a Technical Committee Member of the NFPA 70E Standard for Electrical Safety in the Workplace and is well respected in the electrical industry.

I have written a series of blogs on the proposed changes, organized by Article:

Existing text from 2018 is provided, with changes shown as either strikethrough for deletions or in RED for changes.

Changes to Article 130 (Work Involving Electrical Hazards):

Article 130.1 through 130.3 were reorganized/rewritten and moved to Article 110.

- Section 130.1 General. This article covers work involving electrical hazards when an electrically safe work condition cannot be established and is being moved to 110. 130.1(1) and 130.1(2) were removed and reworded in Article 110. The following is being removed:

- When an electrically safe work condition must be established

- Requirements for work involving electrical hazards such as the electrical safety-related work practices, assessments, precautions, and procedures when an electrically safe work condition cannot be established.

- Section 130.3 Working While Exposed to Electrical Hazards - “Safety-related work practices shall be used to safeguard employees from injury while they are exposed to electrical hazards from electrical conductors or circuit parts that are or can be energized…” will become 130.1 and re-written as:

- “When energized electrical conductors and circuit parts operating at voltages equal to or greater than 50 volts are not put into an electrically safe work condition, and work is performed as permitted in accordance with 110.6 (this is the new 110.6, I believe old 110.2 – Training Requirements), all of the following requirements shall apply:

- (1) Only qualified persons shall be permitted to work on electrical conductors or circuit parts that have not been put into an electrically safe work condition.

- (2) An energized electrical work permit shall be completed as required by 130.2.

- (3) A shock risk assessment shall be performed as required by 130.4.

- (4) An arc flash risk assessment shall be performed as required by 130.5.”

- Section 130.4(A)(2) Shock Risk Assessment – General was rewritten as follows;

- “Estimate of Likelihood and Severity. The estimate of likelihood of occurrence of injury or damage to health and the potential severity of injury or damage to health shall take into consideration all of the following:

- (1) The Design of the electrical equipment

- (2) The electrical equipment operating condition and the condition of maintenance”.

- This additional language was provided for clarity to Article 150.5 Arc Flash Risk Assessment.

- Another way to look at this and when I teach my qualified electrical safety training course; Whether it’s Shock or Arc Flash, the likelihood and severity of occurrence of injury is a possibility if you enter the restricted approach boundary which is typically 12 inches for most us depending on the voltage. Of course, only a “qualified” person can enter the restricted boundary.

- Operating condition and Maintenance: How do you know the equipment is operating correctly or has been maintained. It’s a judgment call.

- “Estimate of Likelihood and Severity. The estimate of likelihood of occurrence of injury or damage to health and the potential severity of injury or damage to health shall take into consideration all of the following:

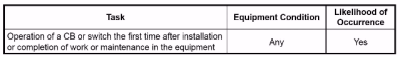

- Table 130.5(C) Estimate the Likelihood of Occurrence of an Arc Flash Incident for ac and dc Systems. The following task was added to the table as YES for:

- Likelihood of an arc flash incident for any condition. “Operation of a CB or switch the first time after installation or completion of maintenance in the equipment”.

- Why was this added? Look up the “smoke theory” which in a way is an anecdote.

However, the old adage was if you throw the switch and you don’t see smoke, it’s likely fine. But if you do see smoke, it means it’s bad and won’t work.

However, the old adage was if you throw the switch and you don’t see smoke, it’s likely fine. But if you do see smoke, it means it’s bad and won’t work.

- Why was this added? Look up the “smoke theory” which in a way is an anecdote.

- Incident Energy Analysis:

- Calculate the perspective incident energy or the severity of the arc flash. Sample arc flash in slow motion: https://www.youtube.com/watch?v=5df06xirApQ

- Based on incident energy, you select the appropriate PPE with an arc rating sufficient to protect you from rated incident energy

- The incident energy analysis is based on IEEE 1584 (2018) which is the latest and 2nd version. The prior version was 2002. You can get a copy at: https://www.techstreet.com/searches/28647146

- Because of IEEE 1584 (2018) changes, NFPA 70E (2021) added new informational notes under Table 130.5(G) Selection of Arc-Rated Clothing and Other PPE When the Incident Energy Analysis Method is Used:

- “Note (e): The arc rating of outer layers worn over arc-rated clothing as protection from the elements or for other safety purposes, and that are not used as part of a layered system, shall not be required to be equal to or greater than the estimated incident energy exposure”.

- The purpose is to still have the outer garment (for example to protect from the cold weather) with an arc rating but the arc rating doesn’t have to be rated equal to or greater than the primary arc rated protection under the outer garment. If there is an arc incident, the outer garment would not ignite and keep burning over and over (because it has an arc rating) but the primary arc rated clothing under the outer garment would ultimately protect you based on the calculated incident energy.

- Example: The primary protection requirement is rated for 50 cal/cm2 but you need to wear an outer security vest. It’s not likely you will be able to find or purchase a security vest with that type of rating. Therefore, a vest with a lesser arc rating would be acceptable.

- “Note (d): Footwear other than leather or dielectric shall be permitted to used provided it has been tested to demonstrate no ignition, melting or dripping at the estimated incident energy exposure”.

- “Note (e): The arc rating of outer layers worn over arc-rated clothing as protection from the elements or for other safety purposes, and that are not used as part of a layered system, shall not be required to be equal to or greater than the estimated incident energy exposure”.

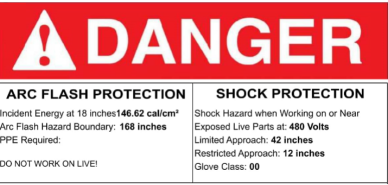

- What if you see an existing label on a switchboard that has an incident energy value of 146 cal/cm2? Your maintenance people need to work on the switchgear and they know they need to place the gear “in a safe work condition”. In order to do that, they need to “verify absence of voltage” as part of the process of putting the equipment in a safe work condition. The issue is you need to wear the proper level of PPE but you do not have PPE rated for 146 cal/cm2 since it is not available commercially.

- Therefore, a new informational note was added under section 130.7(C)(1) Personal and Other Protective Equipment (General):

- “Where the estimated incident energy exposure is greater than the arc rating of commercially available arc-rated PPE, then for the purpose of testing for the absence of voltage, the following examples of risk reduction methods could be used to reduce the likelihood of occurrence of an arcing event or the severity of exposure”.

- NOTE: The arc ratings of commercially provided PPE has been going up considerably but not everyone has access to this PPE and the ratings could still be higher than what the market is manufacturing.

- “Examples of Risk Reduction Methods:

- “Where the estimated incident energy exposure is greater than the arc rating of commercially available arc-rated PPE, then for the purpose of testing for the absence of voltage, the following examples of risk reduction methods could be used to reduce the likelihood of occurrence of an arcing event or the severity of exposure”.

- Therefore, a new informational note was added under section 130.7(C)(1) Personal and Other Protective Equipment (General):

- Likelihood of an arc flash incident for any condition. “Operation of a CB or switch the first time after installation or completion of maintenance in the equipment”.

- “When energized electrical conductors and circuit parts operating at voltages equal to or greater than 50 volts are not put into an electrically safe work condition, and work is performed as permitted in accordance with 110.6 (this is the new 110.6, I believe old 110.2 – Training Requirements), all of the following requirements shall apply:

1.Use noncontact proximity test instrument(s) or measurement of voltage on the secondary side of a low voltage transformer (VT) mounted in the equipment before using a contact test instrument to test for the absence of voltage below 1000 volts

- If equipment design allows, observe visible gaps between the equipment conductors and circuit parts and the electrical source(s) of supply

- Increase the working distance. Typically, the incident energy is calculated from the source of contact to the torso and head. So, by increasing the working distance, the total incident energy will be lower

- Consider system design options to reduce the incident energy level”

- Such as a current limiting device. Note: (IEEE 1814) will be coming into play which will provide some options”

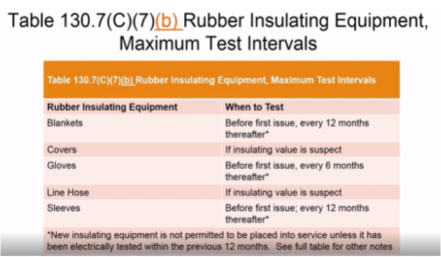

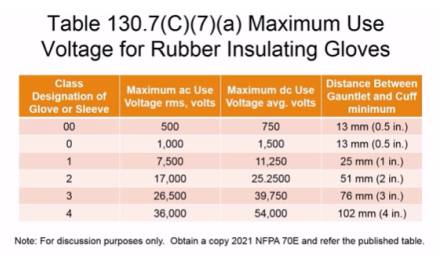

- Table 130.7(C)(7) Rubber Insulating Equipment, Maximum Test Intervals will become two tables:

- 7(C)(7)(b) Rubber Insulating Equipment, Maximum Test Intervals

(EXISTING) and a new table was added;

and a new table was added;

- 7(C)(7)(b) Rubber Insulating Equipment, Maximum Test Intervals

- 7(C)(7)(a) Maximum Use Voltage for Rubber Insulating Gloves (NEW) which will look like this;

Both tables used from Jim Phillips webinar

- Changes to section 130.7(C)(14) Standards for Personal Protective Equipment (PPE). The previous version referenced the ASTM standards that PPE needs to conform to. The 2021 version is now adding the IEC (International Electrotechnical Commission) standards since they are just as important if not more stringent. Therefore, the following was added:

- IEC 61482-1-1 “Live working – Protective clothing against the thermal hazards of an electric arc – Part 1-1: Test Methods – Method 1: Determination of the arc rating (ELIM, ATPV and/or EBT) of clothing materials and of protective clothing using an open arc.” This section is the actual test method. The difference between ASTM and IEC is the “ELIM” which satisfies certain European specific requirements.

- IEC 61482-2 “Live Working – Protective clothing against the thermal hazards of an electric arc – Part 2: Requirements.”

- As mentioned earlier, a brand new article is being added; Article 360 “Safety-Related Requirements for Capacitors

- Contains six sections:

- 1 Scope

- 2 Definitions

- 3 Stored Energy Hazard Thresholds

- 4 Specific Measures for Personnel Safety

- 5 Establishing an Electrically Safe Work Condition for a Capacitor(s) – Specific to Capacitors.

- 6 Grounding Sticks”

- Historically, Capacitors were only referenced a couple times in NFPA 70E. However, they are a significant source of stored energy and a potential hazard.

- Contains six sections:

I realize there is a good deal of information here to digest but I hope this gives you an idea of what’s to come. I want to thank Jim Phillips for helping us all learn more about the proposed NFPA 70E 2021 changes. As always, if you have any questions or want to learn more, please feel free to reach out to our team anytime.

About the Author:

Scott has retired from Hallam-ICS, but his contributions to the company continue to be valued.

About Hallam-ICS:

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

The 2021 NFPA 70E Changes are Coming! 5 Major Changes You Need to be Aware of (Part 1 – Article 100)

The 2021 NFPA 70E Changes are Coming! 5 Major Changes You Need to be Aware of (Part 3 – Article 120 and Annexes)

Comments (1)