Three Common Misconceptions that are Costing You Money-Part 2

by Chris Giusto on Feb 25, 2021 9:45:00 AM

This is the second of a three-part blog series titled “Do we really need to get engineering involved? – Three common misconceptions that are costing you money”:

- Misconception #1: My project is too small/simple to get engineering involved.

- Misconception #2: My contractor can figure it out – just put it in their scope.

- Misconception #3: My vendor is going to provide the engineering.

“Do we really need to get Engineering involved?”

- Misconception #2: My contractor can figure it out – put it in their scope

There are good contractors who perform quality work and are great at solving problems, but having a top notch contractor performing your installation is no substitute for design engineering. Your engineering firm is your partner and your advocate, who has your overall best interests in mind with regard to your projects complete success. Engineers fill a role that a contractor cannot.

Your engineer has a global perspective when it comes to your project, ensuring the final product is safe, performs technically, and generates the ROI you expect. Your site’s standards and considerations for future expansion are also taken into account during the design process. Contractors naturally tend to focus more heavily on the physical installation and the quality of workmanship. That is not a criticism – means and quality of installation is where you want your contractor focused, as it is their area of expertise and is important to a successful project. The danger of course is that you end up with a great looking installation that presents a hazard to your facility and/or personnel, does not perform as intended, and/or does not return the financial benefits you were expecting.

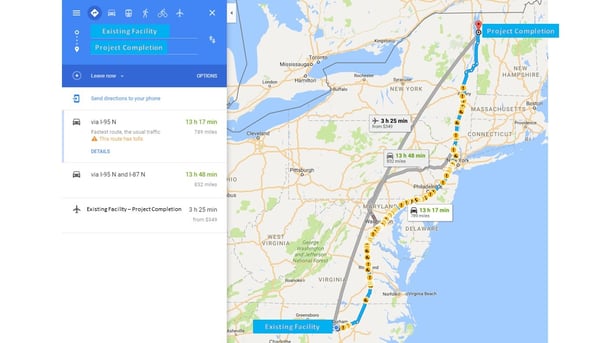

Think of Your Project as a Journey

Your engineer works with you to document a plan—your map—to get you to your destination. Your engineer’s drawings and specifications define your destination – a completed project that meets your expectations – and the route you intend to take to get there so that you arrive on time and on budget. Map in hand, you sit behind the wheel and drive your project to completion with your engineer riding shotgun. But as the driver, your primary focus is on the road immediately in front of you. When the unexpected happens, your engineer can help you overcome surprises by studying the map for options, while you keep your eyes on the road.

The first thing your map does is clearly define the scope of work for your contractor – the route you intend to take to get to your destination. This allows you to get bids that do not contain excessive contingency because the scope is open to interpretation. It will also minimize assumptions by the contractors that can result in large differences in pricing, allowing you to more easily make a fair comparison between bids. Once your contractor is hired, the drawings and specifications have now set an expectation to which you and your contractor have agreed, and they limit your contractor’s ability to make decisions and changes without your knowledge or approval.

The drawings and specifications will also help you navigate surprises with certainty. Even a well-planned route is susceptible to the unexpected – bad weather, traffic jams, detours, etc. Your map provides the information you need to make an informed decision if deviation from your plan is required. With your engineer’s expertise also at your disposal, you are well equipped to make sure you identify and understand the implications of any deviations so you can make an informed decision and avoid surprises after commissioning.

A common mistake contractors (and owners) can make is thinking in terms of average production rates. Modern production facilities often have to be flexible – capable of running at different production rates or able to run multiple products on the same equipment. When you work with an engineer, the flexibility your facility requires gets documented in the drawings and specifications so it is clear for your contractor what is required to meet all of your needs. Your contractor may be able to size and install a pipe for X flow from point A to point B. But your engineer ensures it is also sized for double that flow so you can still run at capacity when line 2 is down, and that it has the correct pump, valves, and instruments to properly provide and control both flow rates. These are the kind of details that are easy to overlook and become very expensive to correct when they are discovered.

Contractors are also naturally motivated to find ways to make the installation easier, which usually results in cost savings for the owner, but can also have unintended negative consequences. That is not to say that contractors cannot have good suggestions. On the contrary, contractors have a tremendous amount of practical experience that can add value in ways most engineers cannot. But even a great contractor who wants you to succeed has a hard time seeing beyond the construction phase. Routes that take less time can have tradeoffs – tolls, increased fuel costs, higher likelihood of congestion, etc. Your engineer can help make sure you don’t agree to make a change saving $10,000 on construction that will result in increasing your operational costs by $1,000 per day.

SIDE NOTE: The ideal time for contractor input is during a constructability review – not in the midst of construction. Constructability reviews will be the topic of one of my future blogs.

Contractor suggestions to deviate from your plan can become especially problematic in the midst of construction when unexpected delays, weather for instance, can cause a project schedule to slip. Your contractor may make suggestions to save time in an effort to get back on schedule which at that moment often seems to be the key to success. Your engineer, who is often a degree removed from the day-to-day excitement of the construction site, can provide a sort of outsider perspective. “Yes, that will save time, but have you considered…” (I know sitting in this traffic is terrible, but if we get off at this exit, while we will keep moving, we will have to go so far out of our way we won’t really save any time.) As your advocate, with a more complete perspective of what defines success for your project, your engineer will help you make the best overall decision for your project, even if it may not seem like the best decision for today’s problem.

Finally, and Most Importantly

An engineer will also look out for your best interests regarding safety. Your engineer considers many safety related aspects during design (code compliance, safety devices, maintenance access, guarding, etc.) and is more knowledgeable about these topics than most contractors. The requirements and accommodations for an installation that is safe to operate and maintain are not always obvious, and are easily overlooked without a well thought out plan.

If you think the topics I have discussed here do not apply to your project because it is too small or simple to get an engineer involved, I would encourage you to read Part 1 of this blog.

About the Author

Chris Giusto is Regional Manager for the South Atlantic and Director of Combustible Dust Safety at Hallam-ICS. He works with clients to improve processes & safety, reduce waste & energy consumption, increase flexibility & capacity, and build new facilities. He has over 20 years of engineering experience and leads Hallam’s Combustible Dust Safety Service offerings. He’s spent nearly his entire career working with combustible dust hazards and designing NFPA-compliant equipment and systems. With additional expertise in material handling and dust collection system design, he and his team bring a comprehensive approach to practical solutions for improving safety and meeting NFPA requirements.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Three Common Misconceptions that are Costing You Money

Three Misconceptions that are Costing You Money- Part 3

No Comments Yet

Let us know what you think