Ventilation of Gas Cabinets and Exhausted Enclosures, Part 2

by William Neuburger on Jan 28, 2021 10:30:00 AM

Gas cabinets and exhausted enclosures are found in many of our client’s facilities, primarily in semiconductor fabrication and research laboratories. The appropriate amount of airflow is not always obvious to the designer. This blog is the second in a series of three that will focus on code requirements and ventilation rates for gas cabinets and exhausted enclosures associated with compressed gases and their distribution.

Part 1: Ventilation of Gas Cabinets and Exhausted Enclosures – Part 1 Overview

Part 2: Ventilation of Gas Cabinets and Exhausted Enclosures – Part 2 Gas Cabinets

What is a Gas Cabinet?

The International Code Council (ICC) and the National Fire Prevention Association (NFPA) harmoniously define a cabinet harmoniously:

International Fire Code definition: A fully enclosed, ventilated, noncombustible enclosure used to provide an isolated environment for compressed gas cylinders in storage or use. Doors and access ports for exchanging cylinders and accessing pressure-regulating controls are allowed to be included.

National Fire Code 3.3.136: Gas Cabinet. A fully enclosed, noncombustible enclosure used to provide an isolated environment for compressed gas cylinders in storage or use. [55, 2013]

Gas Cabinet Applications

- Used to increase maximum allowable quantities for certain hazardous materials in a control area

- Best practice by some owners for any hazardous compressed gas

- Sometimes statutory for any gas (health hazard gases in NFPA codes for example – corrosive, toxic and highly toxic)

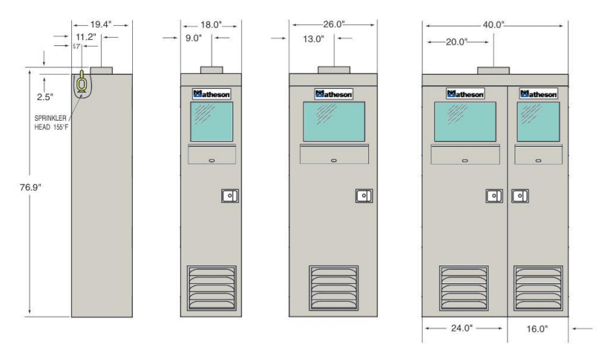

Most gas cabinets share these features:

- Between 6’ and 7’ tall, with an electronic controller on top.

- About 2’ by 2’ in plan (wider for three-cylinder units) with the entire front as openable for cylinder changes.

- Contains the gas cylinder or cylinders, pressure and flow controls, safety features.

- The configuration of control elements varies by application and user requirement.

- The front of the cabinet:

- Is entirely openable for cylinder change.

- Has an openable access port or door (usually safety glass) through which the gas control panel is visible and accessible.

- Has slots or adjustable louvers to allow air to flow in and around exhaust neck on top for duct connection, often 6” or 8”.

- The gas cabinet’s purpose is to provide a physical separation of the compressed gas cylinder and controls from users.

- The gas controls range from a very simple combination of a regulator and isolation valve to complicated auto-switchover configurations with automatic purging features to improve cylinder replacement safety and purity.

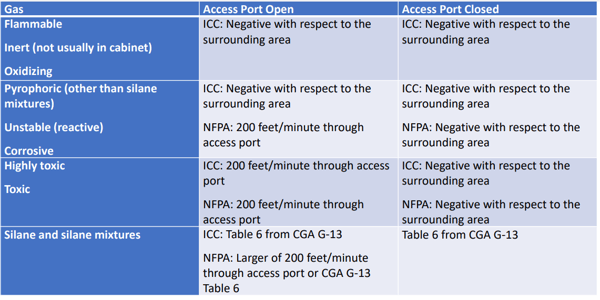

ICC and NFPA Gas Cabinet Ventilation Code Requirements

Chapter 50 of the International Fire Code and chapter 63 of the National Fire Code define the reequipments for gas cabinets, including ventilation. They are generally identical with minor (but nontrivial) differences. Designers should carefully review the relevant chapter of the statutory code before commencing design.

The last blog in this series will cover ventilation for exhausted enclosures in a similar fashion, and advice for designers working on gas cabinet and exhausted enclosure installation.

About the Author

Bill has been a mechanical engineer since 1995 and with Hallam-ICS since 2010. His career has brought him to the top of the Transamerica Pyramid Center, chemical plants, underground mines, paper mills, and semiconductor fabrication facilities. He has experience designing, specifying and installing mechanical and electrical systems in the built environment covering industrial, institutional and commercial facilities.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Why Gas Monitoring Should Never Be Together with Gas Cabinets, And, Why Gas Monitoring Should Always Be Together with Gas Cabinets

Ventilation of Gas Cabinets and Exhausted Enclosures, Part 1 Overview

No Comments Yet

Let us know what you think