Arc Flash Engineers, The Unsung Heroes

by Chris Font on Jul 18, 2019 10:25:00 AM

Electricians all across the country hear “arc flash study” and think of one thing fast - personal protective equipment or PPE for short. Frank is a maintenance man and doesn’t like that his place of work is about to have an arc flash study completed.

His buddy that works at a nearby plant told him that they just had an arc flash assessment and now their equipment have these fancy labels full of gibberish. Frank’s pal warned him that these labels require him to sometimes dress up in uncomfortable clothing just to install a new 120V breaker on an existing lighting panel. Frank’s friend is right about a few things; once an arc flash study is completed, the equipment in the field must be labeled with an arc flash hazard warning (2014 NEC 110.16). The label is required to inform qualified workers of three main components (2015 NFPA 70E 130.6(D)):

- System voltage

- Arc flash boundary

- At least one of the following:

- Minimum Arc Rating of Clothing

- Site-Specific level of PPE

- Available incident energy and the corresponding working distance or the arc flash PPE category for the equipment, but not both.

Incident energy is the amount of thermal energy released during an electrical arc event and is what dictates the necessary level of PPE. Once the equipment is labeled properly, workers know exactly how much energy can be released and what level of PPE will protect them from this energy. As the energy levels increase so do the amount and weight of PPE. There are some instances where incident energy values are so high no single garment currently exists to withstand it. These cases are too dangerous to be worked on energized. Qualified workers like to see low levels of incident energy because it means they don’t have to “suit up.” Suiting up is bulky, hot, and not to mention very uncomfortable. A cotton shirt is suitable protection for a low energy event, which is the much more preferred attire.

Keeping incident energy values low is always a goal of Hallam-ICS while conducting power systems studies. Of course this makes for a safer work environment, but it also makes it more likely that the people working on this equipment will choose to conform to the levels of PPE listed on the label.

Lowering incident energy is not the only focus of a Hallam-ICS power systems study. Another key component is the coordination study. A coordination study summed up in a few words is making sure that overcurrent protection devices (OCPD) trip in the order they are supposed to. For example; the main breaker of a lighting panel should trip before OCPDs upstream of it. When all devices trip in the order they are supposed to they are well coordinated devices. Cases where devices are not coordinated may result in the loss of power in more areas than should be affected and even cause nuisance tripping.

Unfortunately, in systems that were designed without arc flash hazards in mind, adjusting settings to improve coordination usually results in higher incident energy values. Facilities may prefer to reduce incident energy values at coordination’s expense or vice versa. Generally, most places prefer the middle-of-the-road approach. Implementing this technique means coordinating devices without increasing incident energy above the existing values.

The true accolade is good coordination which also results in a decrease in incident energy. These situations do come about from time to time and are the moments us engineers at Hallam-ICS get to feel like champions. Upon delivery of our report our client does not know what the existing incident energy values were. They get the final values and their equipment is labeled to reflect this potential incident energy. In the background we have solved that pesky breaker from tripping every time the supplemental cooling unit starts up in the heart of summer. Also, remember that breaker that used to trip all the time before the maintenance staff “fixed” it back in ’09? That was solved by cranking the instantaneous trip setting to its maximum value. Sure, it stopped the breaker from tripping but it also raised the incident energy from 8 cal/cm2 to 42 cal/cm2! Don’t worry, we dialed that breaker’s instantaneous setting right back to where it belongs. No more tripping and no insanely high levels of PPE for energized work.

Often times a power systems study is conducted to ensure adequate protection of the facility's employees or to figure out why the electrical distribution system is not functioning properly. More commonly they are conducted to comply with OSHA standards. Engineers at Hallam-ICS have passion in our jobs and know that people’s lives depend on our work. For this reason we always attempt to make energized equipment as safe as possible while maintaining system efficiency.

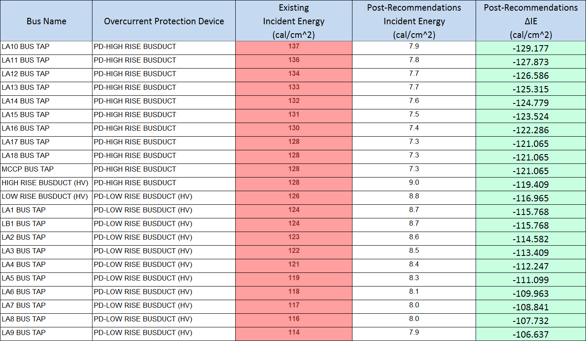

Recently, a job has been completed where 22 (see table) buses saw a reduction in incident energy by more than 100 cal/cm2! The greatest decrease was from 137 cal/cm2 to 7.9 cal/cm2. All buses affected were a result of setting changes that were made to better coordinate OCPDs.

At the end of the day, Frank the maintenance worker might still complain about the 8 calorie-rated PPE he must wear to work on the same equipment he’s been working on forever. When in reality, thanks to the coordination study, he would’ve been wearing a 100 calorie-rated suit.

About the author

Chris Font has left Hallam-ICS to pursue other endeavors, but his contributions to the company continue to be valued.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Advancing Automation Technology - How to Specify a Domain Controller

Pros and Cons of Different Economizer Configurations for Data Centers

No Comments Yet

Let us know what you think