Diesel–to-Water–to-Gold

by Ray Racine on May 10, 2018 10:30:00 AM

The trend-watchers tell us that water will become the next oil. As populations grow and climate-change shifts the patterns of rain, we are slated to require more and more water where there are the least resources.Providing fresh water to meet this growing need will require investment in infrastructure and in distribution in many places in the world that are very, very poor. The price of water will have to increase in much of the world to fund the required infrastructure. What most of us fortunate enough to live in first world economies don’t understand is that this is already true in much of the world.

A few years back, I had the opportunity to work in West Africa. Mauritania is a very poor country, with an engrained culture of slavery and slave-owning. A land mass 50% larger than Texas with a population similar to Puerto Rico. It is arid and most of the country lies within the Western Sahara (or Sahel) desert.

One of the few resources the country has is in the form of mineral wealth. A gold mine in the desert brought me to West Africa. Hallam-ICS has partnered with ISI many times over the year. ISI is a Vermont-based provider of Reverse Osmosis systems for Municipal and Industrial clients. We provide industrial control systems and support for them on different projects.

So, how does this tie in to my theme of diesel to water to gold? During the build out of this mine, there were over 1000 workers from all over the planet on the site – a site in the middle of the desert. One thousand people drink a LOT of water in a climate with daily summertime highs of 120+ degrees Fahrenheit & single digit humidity. Add to that, the heap leach gold recovery process uses a LOT of water. There is no water here – none. On my arrival at the site, there had been no measurable precipitation in over 2 years – not a drop of rain.

So how do you get water here? Only a few options:

- Ground Water – Nope

- Truck in Potable Water

- This is Reverse Osmosis water from the capital city

- There is no real electrical grid, and what there is, is powered with Diesel

- Most Reverse osmosis systems are powered by generators burning Diesel

- 5-hour truck trip to the site is powered by Diesel

- All Diesel is imported as there is no refining capacity in this country

- Based on the amount of Diesel involved in making this water - This Water is essentially Diesel

- Well Water

- Not here

- There was an aquifer about 30 miles away where they could set up deep wells and pump brackish water to the site

- This water was about 2% salt, so Reverse Osmosis would be required to treat it at the site

- There is no electrical grid; so your electric motors running the pumps, will be powered by generators

- It gets pumped to the site where it is treated in RO Systems that are powered by Diesel

- Based on the amount of Diesel involved in making this water - This Water is essentially Diesel

Now on to the mining process

This isn’t one of those “Gold Rush” shows from Television. This gold doesn’t come out in nuggets. It is bonded to the ore and has to be chemically extracted. The three major ingredients for this are ORE–WATER–CYANIDE. You dig up the ore. You crush the ore to increase surface area. You drip dissolved Cyanide containing solution over the ore. You collect the water. You use electricity to plate out the Gold.

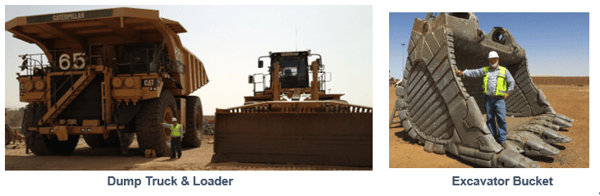

The equipment used in this type of mine is nothing short of colossal. Until you stand next to or in or under the stuff, it is not that easy to comprehend. I am about 5’10 and 250# in these pictures.

We already covered the fact that all water on this site is essentially diesel. So is all electricity. There was not even a site grid; so every area of the mine had diesel generators plugging away 24-7-365. If water is diesel; so is the gold.

The continuous caravan of trucks delivering water and diesel to this site in the middle of the desert was nothing short of amazing. I don’t know how much it costs to get a truck load of diesel from the Arab nations to a port in the Capitol city of Mauritania to the middle of the Sahara; but I bet most of us would change our driving habits if we had to pay these costs for our tank full of gas.

Having lived in a place where everything is diesel (OK based on diesel), I cannot imagine how an ever-more-thirsty-world is going to respond to the challenge of getting water to everyone unless we totally change the way we think and operate. The simple thinking of A or B or C is exactly wrong. In order to get there we are going to have to Pick A and B and C.

The water we drink will have to come from Ground sources AND Wells AND RO Trains. The RO trains will have to treat Waste Water AND Brackish Water AND Sea Water. The energy that moves and treats this water will have to be Wind AND Solar AND Wave generators AND Fossil Fuels (until we ramp up the others).

When I went to Africa for a 3 month job, I expected to gain a little different perspective. I just wasn’t ready for how much and how different those perspectives might be.

About the author

Ray has retired from Hallam-ICS, but his contributions to the company continue to be valued.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Pros and Cons of Different Economizer Configurations for Data Centers

How to Deploy a Hach B7000i Total Organic Carbon (TOC) Analyzer

No Comments Yet

Let us know what you think