How To Properly Apply Pump Vibration Isolators

by William Neuburger on Dec 3, 2019 10:29:00 AM

As engineers we often apply pump vibration isolators between piping and pumps in heating, ventilating and air conditioning (HVAC) systems. Sometimes we should apply these isolators, sometimes we should not and other times they are optional. This blog covers some concepts and guidelines about applying pump vibration isolators.

Why Do We Use Pump Vibration Isolators?

- Pumps have moving parts, moving parts vibrate, we should isolate them

- Rigidly connecting pumps to piping systems can translate vibrations to the building structure, causing objectionable noise and vibration

- Grandma did it that way, so I will too

When Are Pump Vibration Isolators Warranted?

- End suction or double suction pumps not installed in a basement or slab on grade

- Pumps in vibration and sound sensitive areas (facilities with sensitive instruments like microscopes, nunneries, residences)

- Installations with intentional displacement to manage seismic movements

- Where the pump manufacturer requires it (always follow the installation manual)

- Where customer standards mandate it (always follow the paying customer’s standards)

When Can We Eschew Piping Vibration Isolators?

- Inline pumps (usually)

- Basement and slab on grade installations where pump frames are rigidly applied to the floor

What Does A Vibration Isolator In A Piping System Not-Do?

- Manage thermal length changes

- Forgive pipe-to-pump misalignment (figure 1)

Figure 1 Piping-Pump Misalignment

Figure 1 Piping-Pump Misalignment

Braided Hose Pump Connectors

- Allows non-axial displacement (3/8” offset is common)

- Available in many material choices (304 or 316 stainless steel are common)

- Available with many end choices (flange, Van Stone flange, weld end, threaded)

- Inexpensive, common

- Can manage high temperatures and pressures

- See figure 2 for an example of a braided pump connector

Figure 2 Typical Braided Pump Connector (referenced from Metraflex)

Figure 2 Typical Braided Pump Connector (referenced from Metraflex)

- See figure 3 for poorly executed pump connectors

Figure 3 Poorly Executed Flexible Pump Connectors

Figure 3 Poorly Executed Flexible Pump Connectors

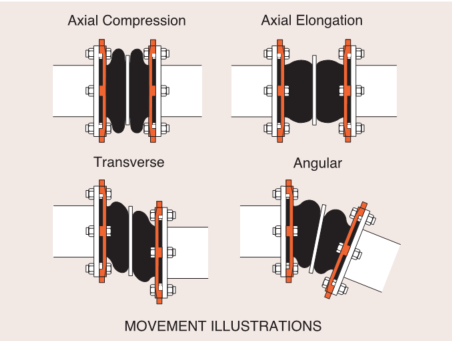

Double Arch Pump Connectors

- Allows non-axial displacement (3/8” offset is common in small sizes, 5/8” is common on 6” pipe size and above)

- Allows axial displacement (similar magnitude as lateral allowance)

- Allows angular displacement (10 to 20 degrees, depending on size; larger size allows less)

- Threaded or Van Stone style flange ends; the gasket is part of the joint, saving the cost of a separate flange gasket)

- May require control cables or rods in larger sizes or higher pressures

- Compared to braided hose, less-capable of high temperatures and pressures, though easily meets most HVAC service demands

- Failure is more likely (though low probability) than braided hose type

- See figure 4 for an example

Figure 4 Double Sphere Isolators (from Mason Inc.)

Figure 4 Double Sphere Isolators (from Mason Inc.)

Where Do We Use Pump Vibration Isolators?

- Non-Isolated Pumps

- Rarely – only if the owner or the pump manufacturer requires it

- If using braided hose pump connectors, install so the pump’s motion imparts non-axial displacement in the connector

- If you are using double sphere or arch connectors, install them where convenient since the isolator moves axially, laterally and angularly

Isolated Pumps

- Contemplate the structural isolator’s movement, direction and magnitude

- Select a pump connector to match the movement of the isolator – for large magnitude movements, you may have to include spring-supported pipe hangers and a second pump connector to allow the full range of motion

- Consider commanding the installer to limit the range of movement on the structural isolators to match the pump connector, if possible within the isolator requirements

Remember

- Always read the installation manual for the pump

- Always listen to your client and read their standards (if they have any)

- Think about how the pump will move, direction and magnitude – plan your isolator to meet those demands

- Ask yourself “can I omit this isolator and save the owner money?”

- Consult ASHRAE Handbook 2015 chapter 48

- Pump systems are unnecessarily isolated (this location is on a slab, in an area of no vibration sensitivity)

- Discharge isolator must flex axially, which is not its usual design

- Uncertain if inlet isolator’s displacement matches the base isolator

About the Author

Bill has been a mechanical engineer since 1995 and with Hallam-ICS since 2010. His career has brought him to the top of the Transamerica Pyramid Center, chemical plants, underground mines, paper mills, and semiconductor fabrication facilities. He has experience designing, specifying and installing mechanical and electrical systems in the built environment covering industrial, institutional and commercial facilities.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Compliance Training Programs: In Person Vs. Virtual

Main Instrument Vendor (MIV) Process Execution - Procure, Receive, Test

Comments (5)