Cryo-Electron Microscopy Laboratories – Planning for Success (Part 1 of 3)

by Jeff Silcox on Sep 16, 2021 8:36:21 AM

Cryo-electron microscopy (cryo-EM), where a sample is studied at cryogenic (liquid nitrogen) temperatures and scanning transmission electron microscopy (S-TEM) are words we are hearing a lot these days. Cryo-EM is sweeping through the field of biology, rapidly replacing x-ray crystallography, providing researchers an unprecedented, high resolution view into molecular structure.

In materials science, S-TEM provides sub-angstrom resolution, permitting researchers to not only see individual atoms, but to identify which element they belong to.

We are seeing a corresponding uptick in inquiries, for microscope laboratories, as our customers have begun adopting this technology. As mechanical, electrical and plumbing (MEP) engineers these facilities are both exciting and challenging to be involved with. In the development of these projects it is essential to understand how the decisions we make, at a macro-level, will come to influence microscope performance at the sub-atomic level.

Mitigating Sources of Interference through Planning

Vibration, noise and electro-magnetic interference (EMI), from both alternating (AC) and direct (DC) current sources, are the enemy of microscope performance. Just as the best target rifle, equipped with the very best scope, will never deliver the satisfactory results in the hands of an unsteady shooter, understanding the sources of microscope interference, and how to mitigate them, are key to a successful installation.

In planning a new microscope laboratory, we consider a hierarchy of mitigation measures to address interference. First, we strive to eliminate the source altogether. Second, we mitigate through passive measures. Only after eliminating the sources directly, and applying passive technologies to those that remain, do we consider active measures. Generally speaking, eliminating risks and applying low technology solutions is preferred. As the level and sophistication of mitigation increases, so does the project cost and risk to microscope performance. In short, when given the choice, choose to keep it simple.

Choosing a Proper Location

With these concepts in mind, selecting an installation site at your facility is perhaps the most important project decision that you will be faced with. Existing buildings are rife with disturbances that can affect your microscope. There is vibration emanating from elevators, mechanical HVAC equipment, foot traffic, process equipment and transformers to consider. Vibration from external sources such as subways, trains and highways affects both new and existing structures. EMI is generated from the obvious sources such as elevators (DC), transformers and motors (AC), but can also be present in metal studs, rebar mats and wire-mold, owing to stray current within the building. Noise from air moving through ductwork, audio visual equipment and classrooms is also present. What to do?

Site Evaluation

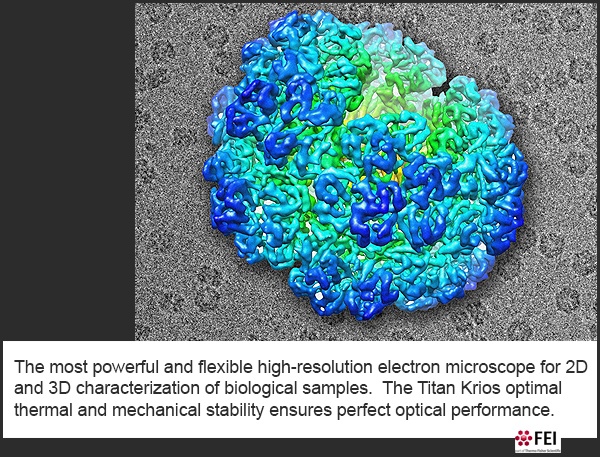

Fortunately, your microscope vendor has established specifications for ambient conditions for vibration, EMI and noise that your site needs to achieve and will educate you in these requirements. We have designed several projects recently involving FEI’s Krios Titan and Themis microscopes. In each case, FEI has retained the services of a vibration consultant to perform a pre-installation survey, evaluating the ambient site conditions at the proposed installation locations, both for renovations and new buildings. The evaluation will include a written report and test data confirming whether or not the site meets the specified criteria. The report may result in some hard choices. Perhaps your preferred location that supports your needs operationally, is not the best choice from a performance perspective. If the proposed site fails to meet specifications in one or more criteria, the vibration consultant can suggest mitigation measures to bring the site into compliance. However, all of these measures come with a cost and at some point, someone is going to ask: How much is all of this going to cost?

Engaging an MEP Engineering Consultant

This is a good, high leverage opportunity to bring in an engineering consultant. We can assist you with evaluating the proposed installation sites and associated mitigation measures. We bring creative ideas, based on our experience, develop concepts, scopes of work and provide cost estimates that combine to help inform your critical decision of site selection. A good choice and good planning will help establish a realistic project scope, budget and timeline, setting the stage for a successful outcome and top performing microscope laboratory.

In our next posts we will delve into the architectural and MEP elements of microscope laboratory design and how these elements of the laboratory construction contribute to EMI, noise and vibration and how to mitigate them.

About the Author

Jeff has retired from Hallam-ICS, but his contributions to the company continue to be valued.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

8 Steps to Create an Electrical Safety Program Part 3

The 4 Steps of an Instrumentation Project Plan

Comments (2)