Pad Mounted Transformer Arc Flash Calculations with SKM and IEEE

by Brian Crosby on Nov 9, 2023 10:30:00 AM

Pad-mounted transformers are commonly used in distribution systems by utility companies, industrial facilities, and commercial buildings, and they are a critical component in power distribution. Despite their importance, pad-mounted transformers can pose a danger if an arc flash occurs. An arc flash is the sudden release of excessive energy, caused by a short circuit or fault, which can cause an explosion, creating a hazardous situation for anyone in the area.

Arc flash events can occur in pad-mounted transformers when there is a fault in the electrical power system. The fault can cause an elevated level of energy to be released, creating an electrical arc that can heat the air around it to several thousand degrees. The arc flash can cause serious injuries, damage to equipment, and even fatalities. The severity of the arc flash is dependent on factors, including the voltage of the transformer, the amount of current flowing through the transformer, and the distance between the electrical equipment and the individual.

To prevent arc flash events, safety measures must be taken when working with or around pad-mounted transformers. OSHA has established safety standards, which require circuit breakers or fuses to be placed in the system to prevent excessive currents from flowing. In addition, the use of personal protective equipment (PPE) is required, such as arc-rated clothing, gloves, safety glasses, and helmets. To further reduce the risk of an arc flash, a hazard analysis should be conducted to identify potential hazards, and all personnel working on or around the pad-mounted transformer should be trained in safety procedures.

In 2018, IEEE released a new update to the arc flash calculations. The formula for calculating arc flash incident energy changed to a broader range of system variables such as distance, voltage, size, and fault currents, thereby providing more accurate results. This new method improves the accuracy of the arc flash calculations.

Does the equipment enclosure influence the incident energy? The answer to this is Yes, the 2018 calculations are based on a 20” x 20” x 20” enclosure then a size correction factor is applied. Think about an open box exploding, releasing energy out the opening. If you have the same explosion with a deeper larger box, the energy release would be less. Size does matter and this is where the size correction factor is applied.

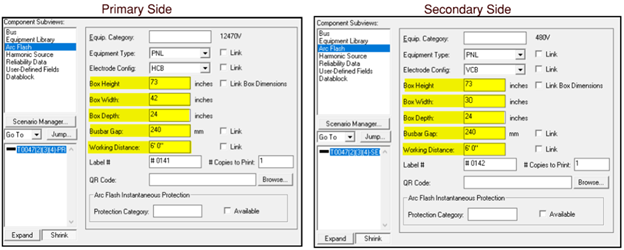

Another change is electrode configuration, bus bars within a panel are they vertical or horizontal, does the end Terminate in an Insulating Barrier or come out towards the individual. These are other variables within the calculations. Software companies such as SKM have included this in their software settings. The choices are:

VCB - Vertical electrodes inside a metal box enclosure.

VCBB - Vertical electrodes terminated in a barrier inside a metal box enclosure.

HCB - Horizontal electrodes inside a metal box enclosure.

VOA - Vertical electrodes in open air.

HOA - Horizontal electrodes in open air.

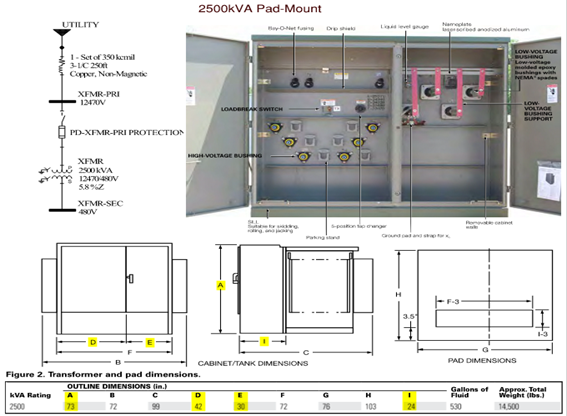

To calculate the incident energy using SKM software and IEEE methods, we first take the dimensions of the transformer primary and secondary compartments.

Next, we add the dimensions to the bus in the software component editor under the Arc Flash Sub-view. We are using a working distance of 6’. Linemen use a hot stick to interact with transformers keeping them 6-10 feet out from energized connections. This also keeps them out of the dangerous arc zone. A Busbar Gap of 10” = 240mm is used to represent the distance between transformer bushings.

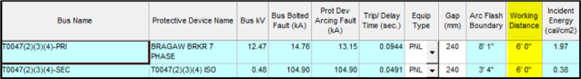

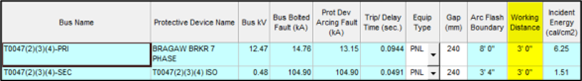

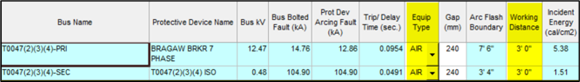

Selecting the proper equipment electrode configuration, HCB on the primary side and VCB on the secondary side with box dimensions and adding Working Distance of 6’-0” then 3’-0” gives us the following results:

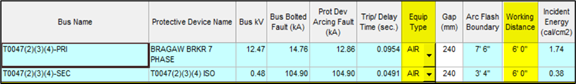

Running the software again using the same Box Dimensions and Working Distances switching the equipment type from panel to open Air provided different result as seen below.

As the results show with all the different configurations and sizes that the incident energy varies. This is much more accurate than the old IEEE-2012 calculation methods, that all equipment is the same size. Using the old IEEE-2012 calculation for the secondary 480V side of the transformer was calculating incident energy greater than 40cal’s.

One of the significant advantages of IEEE 2018 Arc in a Box and Electrode Configuration is its complex formula’s. Software company’s such as SKM make it easy for us to model equipment accurately in real life situations. The technology can be applied to a wide range of power systems, including those with limited space or capacity. This cutting-edge technology can help prevent the most severe accidents that occur in power systems. It represents a major milestone in power systems studies and is an ongoing effort to improve electrical safety and reduce the risk of accidents.

About the author

Brian Crosby is the Arc Flash Safety Supervisor for all Hallam-ICS and runs our arc flash business out of our Raleigh, NC office. Brian has been with the company for over 15 years.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina , Texas, Florida and our projects take us world-wide.

You May Also Like

These Related Stories

Advancing Automation Technology - How to Specify a Domain Controller

Inbound Marketing Outlook 2018

No Comments Yet

Let us know what you think