Top 5 Ways an Arc Flash Hazard Analysis Saves Lives

by Scott King, PMP on Jul 13, 2023 10:41:00 AM

As electrical professionals, we hope that others understand the potential dangers of working around or on live electrical equipment. The reality is that most people do not. It only takes one incident to cause a fatal arc flash explosion. However, by receiving appropriate electrical safety training and following proper procedure, this can be avoided.

In my previous blog, I provided an overview of the issues with Arc Flash Safety and why it’s important to take action. Here are 5 ways that an Arc Flash analysis and Electrical Safety Training can save lives:

#1: It establishes minimum requirements to prevent hazardous electrical exposures to personnel

Most facilities have maintenance staff or on-site electricians who, at times, may need to perform work on live electrical equipment. For example, a healthcare facility’s operating room. Power cannot simply be turned off when a life-threatening operation is in progress. If an issue arises on the upstream electrical distribution system, power needs to be maintained. Therefore, the qualified staff needs to perform live electrical work. If they are not properly trained on the hazards or construction and operation of the equipment, these people could experience a shock or arc flash. An arc flash can cause severe burns, or in some cases, death.#2: It ensures compliance with regulatory agencies

The Occupational Safety and Health Administration (OSHA) is the entity that is enforceable as law. OSHA 1910.333, .335 mandates that all employers, regardless of industry, provide electrical safety in the workplace for all employees and contractors. Whereas OSHA states the law, the National Fire Protection Association (NFPA) guideline NFPA 70E demonstrates how an electrically safe working environment is implemented.

By complying with these agencies, employees and qualified personnel can go home every day knowing that the facility they work in is applying these rules and policies for identified potential danger. Most recently, there was an incident in my area at UNC Chapel Hill and this person was not so lucky. Hallam-ICS personnel are extremely knowledgeable with NFPA 70E and utilize this knowledge to verify that all facilities are in compliance.

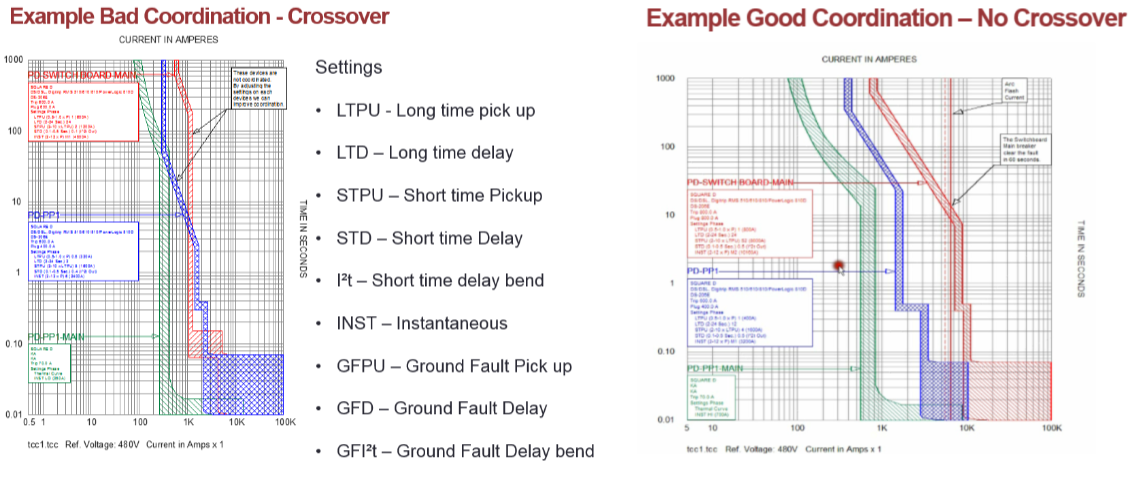

#3: It corrects system coordination and lowers incident energy levels

As part of the analysis, an arc flash assessment is completed to determine levels of incident energy exposure that employees may encounter. The entire electrical distribution system is also reviewed for proper coordination.

If a manufacturing facility is making “X amount of widgets” each day, it’s critical that the electrical system is reliable. Otherwise, the manufacturing line might not always have power. However, if at any point within the system, an electrical “fault” should occur, the protective device at that fault should clear. It’s similar to a circuit breaker in a house that feeds the kitchen receptacles. If a fault occurs, that branch circuit breaker in the main panel board trips to clear the fault and then we reset the circuit breaker.

The same situation happens in a large electrical system; the circuit breaker should trip where the fault occurs. If this does not happen, and the fault travels up through the entire electrical system to the main switchboard that feeds the plant, the main circuit breaker of this switchboard trips instead of where the fault occurred. This is an example of “bad coordination.”  In this situation, the entire plant is now without power and “widgets” are unable to be manufactured. The cost to the facility can be detrimental. However, Hallam-ICS reviews for coordination issues within an electrical distribution system by way of time current curves and provides recommendations to ensure proper coordination within the facility.

In this situation, the entire plant is now without power and “widgets” are unable to be manufactured. The cost to the facility can be detrimental. However, Hallam-ICS reviews for coordination issues within an electrical distribution system by way of time current curves and provides recommendations to ensure proper coordination within the facility.

#4: It establishes minimum requirements to protect specific areas of the body with use of PPE (Personnel Protective Equipment)

Without conducting a risk assessment how would maintenance personnel know what level of PPE to wear? It could be minimal PPE such as non-melting long-sleeve shirt and pants, safety glasses, ear plugs and voltage rated gloves/leather protectors. Or it could be a full blown 40 cal/cm2 body suit (100% body protection). An arc flash hazard analysis will establish the various levels of protection. Qualified electrical safety training reviews the many types of PPE and its “failure” rate of incident energy.

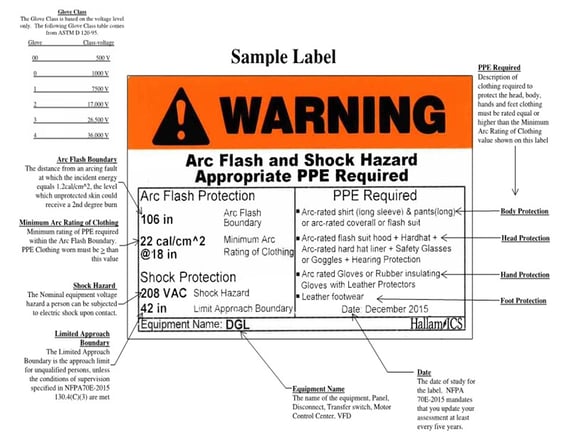

#5: It reduces arc flash hazards with proper labeling

Once the appropriate staff are properly trained in electrical safety and NFPA 70E, they will clearly understand important information like Shock Boundary, Arc Flash Boundary, Incident Energy Levels, Qualified, PPE, Risk Assessment, Working Distances, and much more. In doing so, they will also understand the information outlined on an arc flash label. An arc flash label is applied to all the electrical components included in the arc flash analysis and will include information that qualified personnel will need to know prior to performing live work.

This blog is a continuation of a discussion on the importance of performing an Arc Flash Analysis and Electrical Safety Training at your facility and the benefits of doing so. I hope this information has been helpful. In my next entry, I will break down The 7 Steps to Complete an Arc Flash Analysis.

What type of precautions has your company taken to keep workers safe? Please let us know if you have found any other helpful tips. Also, if you would like to learn more, you can reach out to me directly-sking@Hallam-ICS.com .

About the Author

Scott has retired from Hallam-ICS, but his contributions to the company continue to be valued.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina Texas and Florida and our projects take us world-wide.You May Also Like

These Related Stories

Validation in Life Sciences Projects: Ensuring Compliance and Safety

An Engineer Is Always On-Call

No Comments Yet

Let us know what you think