Where Have My Serial Ports Gone? A SLC5/05 To CompactLogix Solution.

by Ray Racine on Dec 2, 2021 10:30:00 AM

For those of you who, like myself, have been in this automation game for a while, you may have noticed a steep decline in the availability of native serial ports on your PLC. We have all of this fantastic Ethernet connectivity, of which I am a huge fan; but that doesn’t do me any good for all of the legacy stuff I still have to talk to.This is not a nostalgic missive on changing times. It is a realistic look at an issue many of us have, or will, face sooner or later.

I have previously written a series of blogs on Rockwell PLC5 to ControlLogix conversions. I never asked to be our Subject Matter Expert on this; but when you randomly land a few multi-thousand I/O point conversions, it sort of creeps up on you. This is another Rockwell centric blog from me.

PLC5s aren’t the only “long-in-the-tooth” platform from Rockwell. The SLC line is rapidly sun-setting - the older CompactLogix processors are going bye-bye – and the Micro Family members are dropping off. Luckily, the Micro 1100 & 1400 families have held on to their serial ports; but the Compacts are dropping them, and the 1756 ControlLogix line dropped them over 6 years ago (according to a quick check on the silver series page).

A lot of my clients get limited budgets each year; so maybe they get a chance to upgrade an antique PLC running part of their production; but they forgot to budget replacements for some of the peripherals, of which many run on serial communication ports to those legacy PLCs.

Now, there are a ton of solid “linking” products for various old and new network combinations. There are Modbus Serial to Modbus TCP gateways. DH485 to Ethernet I/P, and myriad other combinations. In my experience, most of them work great; but setting them up may require really digging into the manuals and spending more than a little time doping it out. I’m not sure about you; but figuring out the nuances of each of these vendors is hardly what I consider the best part of my job.

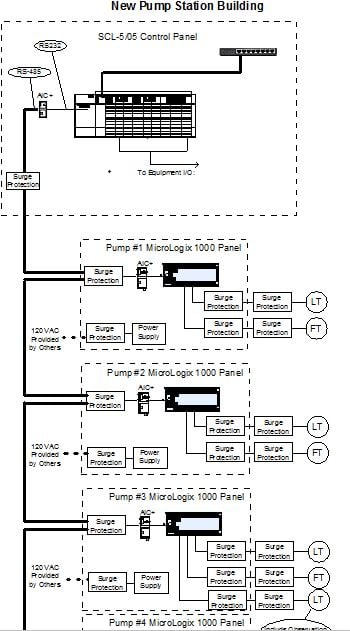

I am in the middle of a SLC Conversion at a client site. For several reasons they are upgrading Soft Starters, and Ethernet connectivity to those simplifies the code and I/O requirements; so it only makes sense to upgrade the PLC, which has served well for many years. The client and I sat down and we decided to go with CompactLogix. Easy enough and/but the old SLC also had five well pump PLCs (MicroLogix 1000) which have no Ethernet options. And (of course) there was no budget to replace the Well PLCs.

Converting SLC logic to CompactLogix is very easy; but a lot of this logic was for messaging to/from the Well PLCs. I did not want to blow a bunch of hours on a gateway; and then it dawned on me. I could copy the communication logic out of the SLC directly into a MicroLogix 1100.

I could use the serial port on the MicroLogix 1100 to the existing RS-232 to RS-485 adapter in the enclosure for the SLC and message the information out of the Well PLCs into the MicroLogix 1100. A single Message Block for Reads and one for Writes between the Micro and the Compact and I had a working solution in a fraction of the time. Now all of my programming was done in familiar Rockwell Software.

This isn’t the solution for every serial port problem; but if you work with a lot of clients with various generations of Rockwell, it might just save you once.

About the author

Ray has retired from Hallam-ICS, but his contributions to the company continue to be valued.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

PLC5 to ControlLogix Conversions – Custom Solutions to Further Reduce Costs

3 Benefits to Hiring a Rockwell PlantPAx Certified System Integrator

No Comments Yet

Let us know what you think