4 Tips for a Productive Engineering Site Survey

by Jon Resnick, PE on Nov 30, 2023 10:30:00 AM

Tip #1

Having a safety plan and regularly practicing recognition of hazards when performing fieldwork is the most important advice I can offer. Even after watching an OSHA video series 4 months ago and forgetting half of what was discussed in it, you’re more at risk of accidents and injury if you don’t stop and actively consider the following each time you go onsite:

- Basic actions associated with your job duties and the hazards associated with them.

- Hazards present in your specific work area. Anything from weather to chemicals to mobile equipment. Challenge yourself to identify as many as possible.

- The required and/or recommended hazard controls (e.g. boots for slips and trips) to mitigate the identified hazards.

- Any client safety training or standards that need to be followed.

Additionally, you should ensure that you know the contact information for coworkers, clients, safety staff, and emergency response services, as well as be familiar with the building or site’s emergency response plan. Last but not least, don’t perform work if it’s unsafe or you don’t have the required training and equipment.

Tip #2

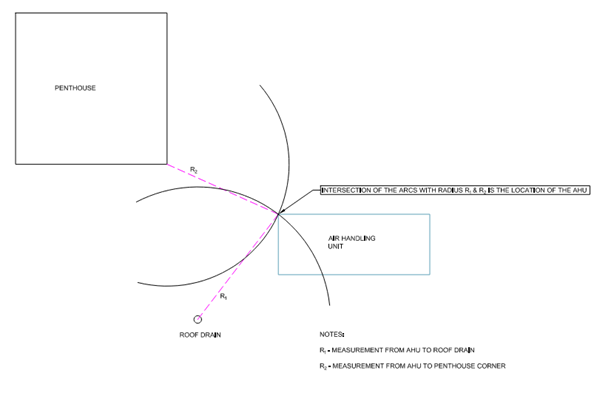

A “Swing Tie” measurement is a useful technique for locating equipment relative to “baseline” object(s) which are already on your plan. Let’s say you’re looking to mark up the location of an existing air handling unit on your roof plan and you have a nearby penthouse and roof drain. Measure the direct length from each object to a corner on the air handler. If you have only one baseline object available, let’s say, the penthouse, you could also use two spots a known distance apart on it.

Using swing tie measurements to locate an AHU

Once you have those two radius measurements, and the size of your object, you can go to CAD and draw two arcs originating at your baseline points, each with their respective measurements as the radius of the arc. The intersections you plot will accurately represent the location of the object on your plan.

Tip #3

Technology has improved the efficiency and accuracy with which we perform fieldwork. About a year ago, I travelled with some coworkers to Ohio where we performed sitework for the modification of utilities to support increasing the capacity of a WFI (water for injection) loop at a pharmaceutical manufacturing site. Ohio is a flight away from my home office, and when we went out there, my coworker brought with him a 360-degree camera. I performed my sitework, making sure to take a million pictures on my iPhone, as usual, while my coworker proceeded to walk around the plant’s utility rooms with the 360 camera elevated at the end of a selfie stick.

When we returned from our site visit and began detailed design, a question came up regarding an existing steam pipe which was tucked away above a host of other utilities and hard to see. Despite all my pictures, I didn’t have a good one of it; consistent with the rule of thumb that the correct number of pictures to take while onsite is N+1, N being the number of pictures you took. Using the footage from my coworkers 360 camera, we were able to produce not only views of the pipe in question but make measurements of it in the camera software!

Different versions of this story have played out for me over my years in consulting engineering, and maybe you as well, but the 360 camera has without a doubt reduced the number of times that I needed to revisit a site or request clarifications after performing sitework. Neat!

Tip #4

About 12 years ago, I was a young college graduate starting my career, and one of my first times performing sitework was at the Empire State Building in NY! Before you get too jealous, we surveyed some relatively dark underground areaways and a few mechanical rooms related to the building’s utilities. In any case, I was excited to get onsite and see the project in real life. I went and dug up the relevant drawings, printed them all, and folded them up. As we were heading out the door, my coworker noticed that my drawings were all full size and told me I should’ve printed smaller. Sure enough, we were walking around doing our measurements and I was fumbling large ARCH D size drawings, trying to get to the right page for a good portion of the time. So, here’s a couple pointers:

- Print your drawings a manageable size for sitework – I find that 17x11 is ideal in most cases.

- Bring some colored pens or felt tips for covering different system types and to make your notes stand out overcrowded as-builts.

- Bring a scale ruler and a couple sheets of graph paper for the occasional detail or elevation you’ll need to draw.

- Bring a heavy-duty tape measure that won’t buckle after unrolling 5 feet.

- Take more photos than you think you’ll need. You can never have too many (see tip #3).

About the Author

Jonathan is a graduate of SUNY Buffalo with a BS in Mechanical Engineering and a registered Professional Engineer in the states of New York, Massachusetts, and Connecticut. He joined Hallam-ICS’s NY office as an Engineering Manager in 2023 and brings over a decade of MEP consulting experience across a wide variety of project types serving the commercial, industrial, and pharmaceutical markets.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina Texas, Florida and our projects take us world-wide.

You May Also Like

These Related Stories

When to Go “Big” with Your Toxic Gas Monitoring System (TGMS)

Learning to Conduct an Arc Flash Survey

No Comments Yet

Let us know what you think