10 Combustible Dust Examples and OSHA Requirements Every Facility Must Know

by Hallam-ICS Editorial Team on Dec 23, 2025 10:30:00 AM

Combustible dust looks harmless. In the right conditions it can drive fires, flash fires, or explosions that stop production and put people at risk. OSHA continues to prioritize inspections for combustible dust hazards through its National Emphasis Program, which directs inspectors to evaluate dust deflagration risk factors across facilities. (OSHA)

If you lead safety, operations, or engineering, your challenge is practical. Identify where dust can form, collect or contain it, control ignition sources, and document compliance steps that stand up to audits. Hallam-ICS helps teams do this work with Dust Hazard Analyses, five-year updates, and mitigation design, but this guide stays focused on what you need to know today.

What is Combustible Dust?

Combustible dust is finely divided solid material that can ignite or explode when dispersed in air and exposed to an ignition source. Many common materials become hazardous in dust form, which is why NFPA publishes combustible dust standards and OSHA enforces related hazards through the NEP. (awpa.org)

Common combustible dust examples include wood, grain and flour, sugar and starch, textile lint, coal or carbon black, aluminum and magnesium, plastic and rubber, pharmaceutical powders, and food powders like cocoa or spices. OSHA expects employers to assess these hazards, maintain housekeeping, train workers, and align with NFPA 660 requirements. (OSHA)

10 Real-World Combustible Dust Examples

Use these examples to map your processes, then verify with a dust hazard analysis and material testing as needed. NFPA 660 requires an initial DHA and updates at least every 5 years.

1) Sawdust and wood dust

Where it appears: Sawmills, furniture plants, pallet shops, MDF manufacturing.

Risk: Fine particulates can ignite from friction, hot surfaces, or electrical faults. Accumulations can fuel secondary explosions.

2) Grain and flour dust

Where: Milling, baking, feed, and grain handling.

Risk: High surface area particulates. Conveying and milling create explosive dust clouds.

3) Sugar and starch

Where: Refineries, confectionery, and beverage plants.

Risk: Powdered sugar and starch are highly combustible. Layering on elevated surfaces increases severity.

4) Textile fibers and lint

Where: Spinning, weaving, and finishing lines; laundry and filter changeout.

Risk: Fibrous lint accumulates in concealed spaces and can flash when exposed to heat sources.

5) Coal and carbon dust

Where: Power, carbon black, pigment production.

Risk: Relatively low minimum ignition energy (MIE) and minimum explosible concentration (MEC) values make these dusts more prone to incidents.

6) Aluminum dust

Where: Finishing, grinding, polishing, machining, and additive manufacturing.

Risk: Metal fines are energetic. Incompatible collection methods can worsen hazards.

7) Magnesium and other reactive metals

Where: Casting, machine shops, 3D printing powders.

Risk: Highly reactive. Water and some extinguishing agents can intensify events.

8) Plastic resins and rubber dust

Where: Compounding, grinding, pelletizing, recycling.

Risk: Many polymers are combustible when finely divided. Static can be an ignition source.

9) Pharmaceutical powders

Where: Blending, tableting, coating, and API handling in cGMP spaces.

Risk: Potent and combustible powders require contained transfer and engineered dust collection.

10) Food powders like cocoa, powdered milk, and spices

Where: Dry mixing, packaging lines, spray drying.

Risk: Highly combustible and easily dispersed during fill and transfer.

OSHA Combustible Dust Requirements

OSHA enforces combustible dust hazards through the National Emphasis Program (NEP) and existing standards. Practical focus areas:

- Hazard assessment and abatement. Identify dust hazards and implement feasible controls. The NEP guides inspectors to look for deflagration hazards across buildings and processes. (OSHA)

- Housekeeping. OSHA’s general housekeeping rule requires workplaces to be kept clean and orderly. For dust, plan cleaning to prevent hazardous accumulations, including elevated and hidden surfaces. See 29 CFR 1910.22. (OSHA)

- Training and labeling. Train workers to recognize combustible dust hazards, follow safe cleaning and hot work procedures, and respond to emergencies consistent with applicable standards. NEP inspection procedures emphasize training review. (OSHA)

- Electrical classification and ignition control. Manage static, bonding, and grounding, and ensure equipment suitability where classified areas apply. These controls are part of NEP inspection considerations. (OSHA)

A Simple Framework to Reduce Risk

1) Complete or update your DHA. NFPA 660 requires an initial DHA and periodic updates. The 2025 edition specifies five-year updates, and DHAs should also be revisited after significant process changes. (awpa.org)

2) Strengthen housekeeping. Define trigger levels for cleaning, include elevated surfaces, and verify methods do not create dust clouds. This is a frequent OSHA focus area under the NEP and 29 CFR 1910.22. (OSHA)

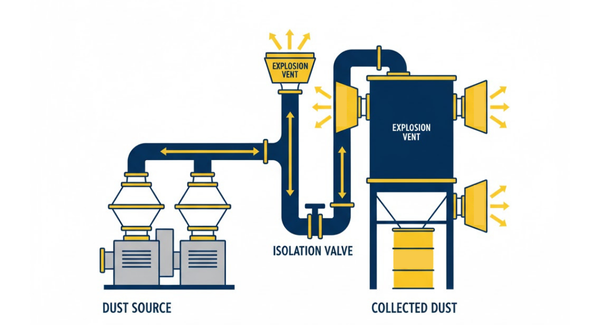

3) Engineer collection and ventilation. Correctly sized hoods, duct velocities, isolation valves, and explosion protection are essential. If you operate dust collectors, review performance and change controls routinely. For a practical dive, see Hallam-ICS guidance on why regular dust collector evaluations are mission-critical.

Internal link: why regular dust collector evaluations are mission-critical

4) Control ignition sources. Bonding and grounding, static control, hot work permits, intrinsically safe devices where required, and proper electrical area classification.

5) Build procedures and train. Train operators and maintenance on safe cleaning, start-up, shutdown, and upset conditions. Capture changes through MOC so new steps get reviewed in the DHA. (awpa.org)

6) Revisit at least every five years. Schedule your DHA update and verify that mitigation items are closed, documented, and auditable. (awpa.org)

Comparison: Housekeeping Program vs. Engineered Collection

|

Consideration |

Housekeeping focus |

Engineered collection focus |

|

Primary goal |

Remove settled dust before it becomes fuel |

Capture dust at the source to prevent accumulation |

|

Strengths |

Lower capital cost, improves inspection readiness |

Reduces airborne dust, supports continuous operations |

|

Gaps |

Labor intensive, may disturb dust |

Requires design, maintenance, and performance checks |

|

Best practice |

Define triggers, frequencies, and responsibilities |

Pair with isolation, explosion protection, and monitoring |

OSHA expects both a clean facility and evidence that systems are designed and maintained to minimize dust hazards. (OSHA)

Where This Shows Up in High-Tech and Regulated Spaces

- Semiconductor fabs: Raw material processing activities can generate dust. Tie dust controls into process control system integration so alarms, interlocks, and shutdowns are visible and actionable.

Internal link: industrial sensor data integration with Ignition - FDA-regulated facilities: Powder handling in pharma and nutraceuticals benefits from contained transfer, verified dust collection, and documented validation. Align dust controls with your quality system and change control.

Internal link: ensure data integrity in cGMP validation processes - General industry: Tie electrical maintenance and NFPA 70E electrical safety programs to combustible dust efforts to reduce ignition sources and improve reliability.

Internal link: NFPA 70E electrical safety programs

Helpful Hallam-ICS resources

- Build your program with this step-by-step guide: 7 steps to complete a Dust Hazard Analysis

- Operationalize improvements: how to implement a combustible dust safety program using the combustible dust safety cycle

- Keep equipment performing: why regular dust collector evaluations are mission-critical

FAQ: Combustible dust, NFPA, and OSHA

What is combustible dust?

It is a finely divided solid material that can ignite or explode when dispersed in air and exposed to an ignition source. Many common industrial materials are combustible in dust form. (awpa.org)

Which NFPA standards apply to combustible dust?

As of 2025, NFPA 660 has consolidated and replaced NFPA 652 and the industry- or commodity-specific standards.

How often should a dust hazard analysis be updated?

Update at least every five years per the 2025 edition of NFPA 660, and after significant process changes. (awpa.org)

What does OSHA require for combustible dust?

OSHA enforces through the NEP and existing standards. Expect inspectors to look for a dust hazard analysis, housekeeping under 29 CFR 1910.22, training, ignition control, and alignment with NFPA 660. (OSHA)

What housekeeping basics reduce risk?

Keep surfaces clean, include elevated areas in your plan, and use cleaning methods that limit dust clouds. Define trigger levels, frequencies, and responsibilities in writing. (OSHA)

Let’s Make Your Program Audit-Ready

If you are evaluating ways to improve compliance and operational performance, our engineers are here to help. Let’s discuss how Hallam-ICS can support your next DHA, five-year update, and mitigation design so your people go home safe and your processes keep running.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina and Texas, and our projects take us world-wide.

You May Also Like

These Related Stories

What is a Dust Hazard Analysis (DHA)?

Combustible Dust Fundamentals & NFPA 652

No Comments Yet

Let us know what you think