Do Breweries Need a High Hazard Building Classification?

by Ash Kreider on Apr 25, 2024 10:30:00 AM

The craft brewery scene near Hallam-ICS’s South Burlington office is excellent. In fact, Vermont has more breweries per capita than any other state in the United States. This is according to data from the Brewer’s Association for 2022.

Brewery tours are a popular pastime among locals and visitors to the area. I’ve found that most brewery tour participants wonder about ethanol-water mixture properties, fire risk, and the occupancy classification of the brewery. This is based on data gathered from a survey of 1 in my personal brain. If you have also wondered about this, or if you are considering opening a new facility, fear not. This blog dives into liquid properties and some odd code intricacies to help you understand this better.

What Are Occupancy Classifications and Why Do They Matter?

The building code defines the type of occupancy group of a building or part of a building based on what the building will be used for. See below for a few generic examples.

- Elementary school: Educational Group E

- Bicycle manufacturing facility: Factory Group F-1

- Assisted living facility: Institutional Group I-1

- Factories with significant quantities of combustible materials: High-Hazard Group H-3

- Semiconductor facility: High-Hazard Group H-5

- Drug store: Mercantile Group M

- Storage building: Storage Group S

These occupancy groups drive design features for that building. In the case of an alcohol producing or processing facility the building is likely either Factory Group F-1, Factory Group F-2 or High-Hazard Group H-4.

The building’s occupancy class drives requirements for building features. You can probably imagine that the buildings listed above should not all be built the same way. For alcohol producing or processing facilities, factory group occupancies require fewer fire protection features than high-hazard occupancy groups. This makes a high-hazard occupancy group more expensive.

Important Ethanol-Water Mixture Properties

Both International Code Council and National Fire Protection Agency codes use flash point as the metric to determine how ignitable a liquid is. This is generally a good metric, but there are many other properties that affect the fire risk of a liquid.

In the case of ethanol-water mixtures, the flash point is relatively high even at low ethanol concentrations, but properties like the energy density and solubility suggest that the fire risk is lower than a single component liquid with a similar flash point.

Flash Point

Flash point is the lowest temperature that a liquid will produce an ignitable vapor above the liquid. In general, a low flash point indicates a higher fire risk. For single component liquids, using flash point as an indicator of fire risk makes sense.

In the case of a two component mixture like an ethanol-water mixture, things get a bit more complicated. The vapor evaporated from a two component mixture will contain a higher concentration of the more volatile liquid than the liquid concentration. In this case, more ethanol will be present in the air above an ethanol-water liquid, which leads to a lower flashpoint (more fire risk) than if equal quantities of water and ethanol were to evaporate.

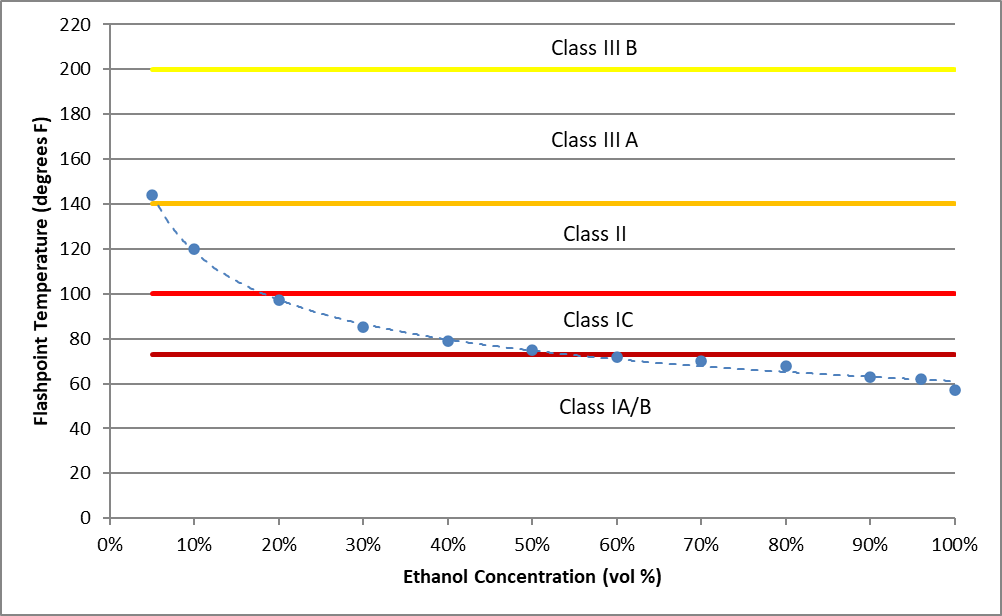

Figure 1 shows flash points for various concentrations of ethanol. Figure 1: Flashpoint of Ethanol-Water Mixtures

Figure 1: Flashpoint of Ethanol-Water Mixtures

Energy Density

The lower heating value of a liquid is the amount of heat released when a liquid is burned. A higher value is worse for a fire scenario.

Pure ethanol has a lower heating value of 76,330 BTU/gallon. For comparison purposes, this is 40% less than gasoline’s lower heating value of 114,000 BTU/gallon.

As ethanol concentration decreases, the energy available to burn also decreases. Additionally, in a fire event, the water portion of this mixture cools the solution down when it evaporates, reducing the energy released even more. At approximately 11% ethanol by volume, the energy from ethanol’s combustion is not even enough to boil the water in the remaining 89% of the solution, much less sustain combustion.

What does this mean for a brewery? Well, for a beer with an ethanol content less than 11% by volume, the net effect will be to cool a fire down. At some concentration above 11% an ethanol solution may contribute additional heat to the fire. What concentration is that exactly? The “Recommended Fire Protection Practices for Distilled Spirits Beverage Facilities” published by the Distilled Spirits Council of the United States (DISCUS) claims that solutions below 20% ethanol by volume are not flammable but does not provide further data for this claim.

Water Solubility

One important property of ethanol is that it is completely miscible in water. In a fire event with a sprinkler system, the sprinkler system will provide water that reduces the concentration of ethanol. This is not unique to ethanol, but there are many oil based flammable liquids that are more difficult to extinguish because they do not readily dissolve in water.

Code Requirements

Code Conclusions

This topic gets a bit detailed, so I’ll give you the conclusions up front. The occupancy requirement depends on which codes and editions are effect in your area. You can check your local municipality web site for this information.

In general:

- The newer editions of the International Code Council codes allow for F occupancy for alcoholic beverage producing facilities.

- Older International Code Council based codes and all NFPA based codes require a high-hazard occupancy.

- We recommend talking to your local Authority Having Jurisdiction early about this. They may be amenable to a code variance for a facility that does not pose a high fire risk.

Statutory Codes

States and municipalities have their own set of statutory codes. Usually, these codes adopt existing codes and make minor amendments. It is important to always check the local codes to confirm, but in general these are the adopted codes in the United States. Note that the code edition adopted also varies by state and municipality.

- Building Code

- International Building Code (IBC) as published by the International Code Council (ICC)

- Fire Code – One of the following:

- The National Fire Protection Agency (NFPA) 1

- The International Fire Code (IFC) as published by the International Code Council (ICC)

The building code and fire codes follow the NFPA 30 definitions of flammable, combustible, and ignitable liquids. NFPA 30, the Flammable and Combustible Liquids Code, classifies liquids based on the liquid’s flashpoint and boiling point.

Maximum Allowable Quantities

Fire and building codes define the Maximum Allowable Quantities (MAQs) for building occupancy groups. If the building will have a quantity above the MAQ, the building requires a high-hazard (group H) occupancy group.

High-hazard occupancy groups are common in industry, but they require additional features that make the building more expensive. Most of the additional requirements are detailed in chapter 4 of the International Building Code. Some of the important requirements are:

- Fire separation from other occupancies in the case of a mixed occupancy building.

- Fire suppression sprinklers are required.

- Emergency alarm systems are required.

- For ignitable liquids, there are specific requirements for floor liquid-tightness, drains, explosion venting, and enhanced fire protection systems.

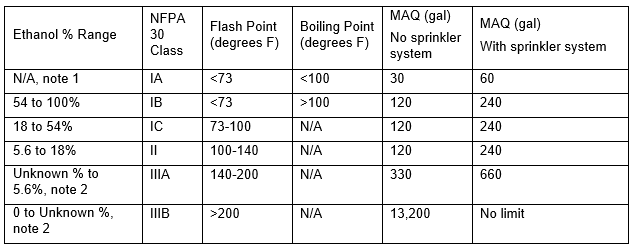

Table 1 provides Maximum Allowable Quantities (MAQs) for various ethanol-water mixture concentrations specifically for the editions listed below. These values are relatively consistent across codes and editions.

- The 2021 edition of NFPA 1, Table 60.4.2.1.1.3.

- The 2021 edition of the International Fire Code, Table 5003.1.1(1).

Table 1: Maximum Allowable Quantities for Ethanol-Water Mixtures

Note 1: Ethanol’s boiling point is 173 F, so even pure ethanol is not class 1A.

Note 2: Available flash point data does not list values for concentrations below 5% ethanol. There is some concentration where the flash point is greater than 200 F and therefore the liquid is a and class IIIB liquid. This concentration is likely below 3% ethanol, so this information is not of practical use for ethanol producing or processing facilities.

Note 3: Additional storage is allowed for storage within approved storage cabinets. That information is not included in this table because it is not practical to store large quantities of ethanol based liquid in storage cabinets.

You might notice that the MAQs are very low compared to what even a small brewery would have to store and process. It would be difficult to brew enough 5% beer to make a profit with only 660 gallons to work with and even harder with a higher alcohol beer. This requires most breweries, wineries, cideries, and other alcohol producing and processing to be a high-hazard occupancy.

Factory Group Occupancy Definitions

The International Building Code has two categories for factory industrial buildings.

- F-1: Moderate-hazard factory industrial

- F-2: Low-hazard factory industrial

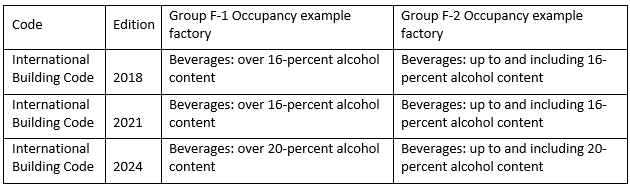

The definitions for these two categories include examples of factories that fall into this category. Examples include appliances, bicycles, boats, clothing, furniture, and many others. There is an alcoholic beverage example as well. See Table 2.

Table 2: F Group Example Factories

At first glance, these examples seem to imply that alcoholic beverage producing factories should be F-1 or F-2 occupancy, not H occupancy since they clearly fit the definitions given for F-1 or F-2 occupancies. Unfortunately, these examples do not act as exceptions to the MAQs, so this is not as helpful as it first appears.

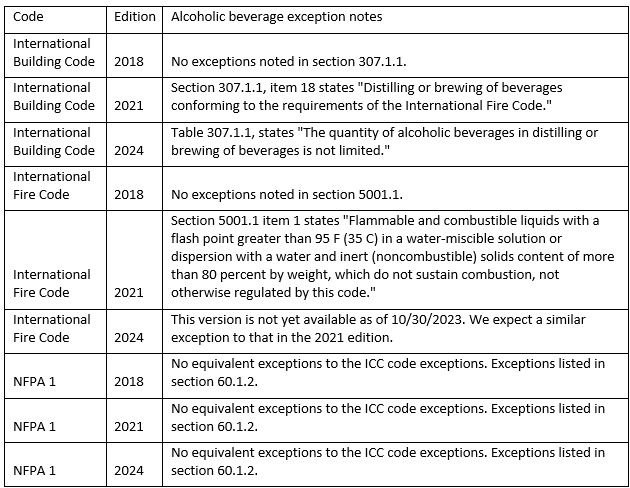

Code Exceptions

As I mentioned before, flash point is a fairly good metric for single component liquids, but imperfect with two component mixtures like an ethanol-water mixture. It appears that the International Code Council has taken this into account in more recent code editions and provided exceptions for distilling and brewing alcoholic beverages. This is true for the International Building Code and International Fire Code. NFPA 1 does not have such exceptions. See Table 3 for specific exception wording.

Table 3: Code Exceptions

This is good news if your local fire code is IFC 2021 or later. If so, you do not need a high-hazard occupancy anymore for an alcohol content up to 20% alcohol by weight (about 25% alcohol by volume).

The ICC uses “brewing” specifically. As someone who has produced homemade beer, cider and wine throughout the years, this wording makes me cringe a bit. You don’t brew cider or wine. You make it. The alcohol producing part of the process is nearly identical for these beverages from a chemical standpoint. I believe the wording is intended to include cider, wine and any other fermentation, but that is not clear. An Authority Having Jurisdiction (AHJ) may argue that these exceptions only apply to beer.

Explosion Risks and Electrical Classification

The explosion risk in a facility is another important consideration for ethanol producing and processing facilities. NFPA 70, the National Electrical Code, addresses these risks with respect to flammable liquids. In general, areas where an ignitable atmosphere is possible require electrical classification to prevent providing an ignition source. An example of a common risk is a high alcohol content spill near a motor or other ignition source. Vapor from the spill could form an ignitable atmosphere and cause an explosion.

We recommend working with architects and engineers who are familiar with these risks and some of the common solutions. Often a solution is simply locating electrical equipment intelligently.

In addition to following the code we recommend performing a Process Hazard Assessment (PHA). This is a structured process designed to identify risks in a process. Performing this early in the design process can help prevent costly changes later.

Codes and Standards Online

- International Code Council codes are available free of charge at https://codes.iccsafe.org/.

- National Fire Protection Association codes and standards are available with a free account at https://codesonline.nfpa.org/.

In closing, the classification of breweries in addition to other alcoholic beverage facilities, within building codes is a nuanced topic with significant implications for design, safety, and cost. Understanding the intricacies of occupancy classifications, ethanol-water mixture properties, and code requirements is essential for brewery owners, architects, and engineers alike.

As the craft brewery scene continues to thrive, proactive engagement with regulatory frameworks and best practices will be paramount for fostering a safe and vibrant industry. Cheers to innovation, safety, and the pursuit of exceptional brews within a framework of responsible design and operation.

About the Author

Ash Kreider is a Mechanical Engineer at Hallam-ICS. He has process engineering experience in multiple industries. He currently designs systems for a wide range of applications including gas distribution, cryogenic fluid recovery, process equipment hookup and HVAC.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina Texas, Florida and our projects take us world-wide.

You May Also Like

These Related Stories

The Importance of Mental Health Awareness in the Work Place

Harmonizing Code and Best Practices for Toxic Gas Monitoring Systems

No Comments Yet

Let us know what you think