Programming with Rockwell Automation's PlantPAx

by Thomas Toppin on Sep 30, 2021 11:30:00 AM

For those new to PlantPAx, this post provides a brief overview of the system and highlights some of the features that make it a modern-day distributed control system. PlantPAx is a plant-wide control system that uses a common automation platform to seamlessly integrate process control, discrete control, and plant-wide information.

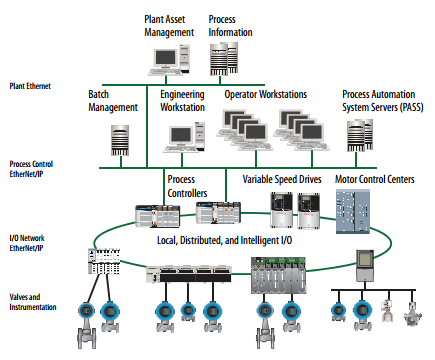

The system is designed to be scalable and modular, supporting a range of architectures depending on application needs. Unlike many traditional DCS platforms, PlantPAx uses open communication standards through EtherNet/IP. This allows for easier integration of off-the-shelf products and enables real-time data to be shared from the control layer up to the enterprise level, which is especially valuable during system upgrades such as PLC-5 to ControlLogix conversions.

To ensure performance and consistency, PlantPAx systems must follow specific design criteria. Rockwell Automation provides a PlantPAx system selection guide to assist with selecting the appropriate architecture and components for each application.

Although this blog series focuses on PlantPAx programming methods, it is important to first understand the key elements that make up a PlantPAx system. For a deeper technical dive into controller organization and application layout, you may also find our post on PlantPAx program structure and controller configuration helpful. The following sections outline the core system elements and include a diagram of a typical PlantPAx architecture to help establish that foundation.

Core PlantPAx Software Components

PlantPAx systems rely on a suite of Rockwell Automation software tools that support configuration, development, visualization, batch control, and data analysis. At the core of this environment are the Studio 5000 and FactoryTalk platforms used throughout the system lifecycle.

Engineering and Configuration Software

-

Studio 5000 Logix Designer application

Used to develop and maintain controller logic, including PlantPAx Add-On Instructions and user-defined data structures. -

Studio 5000 Architect application

Supports system-level design, controller relationships, and overall PlantPAx architecture planning.

Visualization and Operations

-

FactoryTalk View software

Provides the HMI layer used by operators and engineers to monitor and interact with the process.

Batch, Asset, and Data Management

-

FactoryTalk Batch software

-

FactoryTalk AssetCentre software

-

FactoryTalk VantagePoint software

-

FactoryTalk Historian software

These applications support batch execution, asset management, reporting, and long-term data storage, enabling deeper insight into plant performance.

PlantPAx Server and Workstation Architecture

A typical PlantPAx system uses a distributed server and workstation architecture to separate engineering, operations, and data services while maintaining performance, security, and scalability.

Process Automation System Server (PASS)

The PASS server is a core system component that hosts the data server, alarm server, and HMI server.

Engineering Workstation (EWS)

The EWS is used for system configuration, application development, and ongoing maintenance.

Operator Workstation (OWS)

The OWS is where operators interact with the process control system and is not intended for maintenance or development tasks.

Operator Workstation Application Server (AppServ-OWS)

Uses Remote Desktop Services (RDS) to deliver HMI sessions to multiple thin clients.

Historian Server (AppServ-Info)

Hosts the historian application used to collect, manage, and analyze process data.

VantagePoint Server (AppServ-Info)

Hosts the FactoryTalk VantagePoint application for reporting and visualization of plant data.

SQL Server (AppServ-Info)

Used by FactoryTalk Batch, AssetCentre, and VantagePoint to store and access process data, as well as FactoryTalk Alarms and Events.

Asset Management Server (AppServ-Asset)

Supports maintenance and plant operations through diagnostics, real-time monitoring, and calibration.

Batch Management Server (AppServ-Batch)

Manages recipes, materials, and procedural control.

Domain Controller

Stores user account data, authenticates users, and enforces security policies within the PlantPAx system.

Control Layer

Process Controllers (PLCs)

Logix controllers execute the control logic and interface directly with field devices and instrumentation.

Now that the core software components and system architecture are established, it’s worth focusing on one of the key advantages of a PlantPAx system: the library of process objects.

The PlantPAx library includes predefined Add-On Instructions, global display objects, and faceplates that have been tested for functionality and performance. These standardized objects provide consistency for both operators and engineers, reduce development time, and simplify long-term maintenance.

Hallam-ICS engineers regularly apply these standards as part of our work as a PlantPAx-certified system integrator, ensuring systems are designed and programmed in accordance with Rockwell Automation best practices.

During a recent PlantPAx implementation for one of our clients, we were particularly impressed by the development efficiency enabled by these libraries. In the following sections, this series explores the methods, best practices, and tools used to streamline both HMI and PLC development.

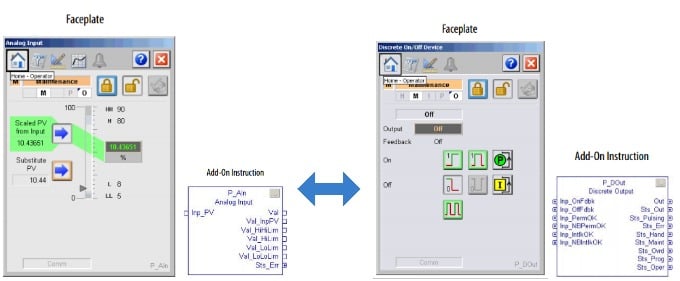

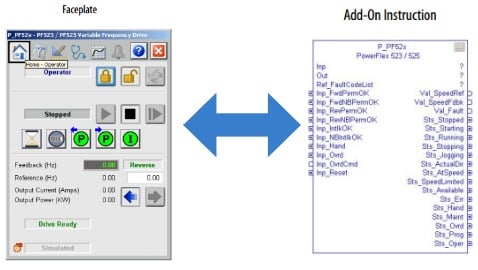

What Is the Library of Process Objects?

To follow the topics discussed throughout this series, it is important to understand the PlantPAx library of process objects. The library is a suite of predefined controller code, known as Add-On Instructions (AOIs), along with standardized display elements and faceplates provided and supported by Rockwell Automation.

Each AOI is developed for a specific function, ranging from digital inputs and analog signals to PID controllers and PowerFlex drives. Inside each AOI is prebuilt logic that has been developed and tested by Rockwell for its intended application. This tested logic helps reduce development time and improves consistency across the control system.

AOIs and Faceplates

Each AOI has a corresponding graphic display, or faceplate, that communicates directly with each instance of the instruction. Faceplates are used to configure, maintain, and operate the AOI, allowing operators to make changes to the process control system without accessing PLC logic.

From the faceplate, users can configure:

-

Scaling and engineering units

-

P&ID tag names

-

Delay setpoints

-

Alarm names, setpoints, and severity

This approach allows many changes that would traditionally require PLC programming to be handled directly through the HMI.

Object-Specific Capabilities

Each AOI and faceplate has capabilities specific to its application. For example, an analog input object (P_AIn) includes different features than a discrete output object (P_DOut). While the functionality varies, the overall structure and behavior of the objects remain consistent across the library.

Consistent Structure and Naming Conventions

All PlantPAx process objects are created using Function Block Diagram (FBD) format and include clearly defined input and output parameters that can be easily connected and mapped. A consistent naming convention is used throughout the library to make the purpose of each tag immediately clear.

For example:

-

All input parameters begin with Inp_

-

All configuration parameters begin with Cfg_

When applicable, these same naming conventions are used across different AOIs, which helps engineers quickly understand and troubleshoot unfamiliar objects.

Standardized Faceplate Layout

Each faceplate follows the same general layout and uses consistent icons and navigation elements. At the top of every faceplate is a set of tabs that open different screens related to that object. Most faceplates include a common set of tabs, with additional tabs added only when required for specific object types.

This standardized layout allows operators and engineers to move between different objects without needing to relearn the interface. Faceplates also include built-in security, ensuring that only authorized users can make specific changes to the system.

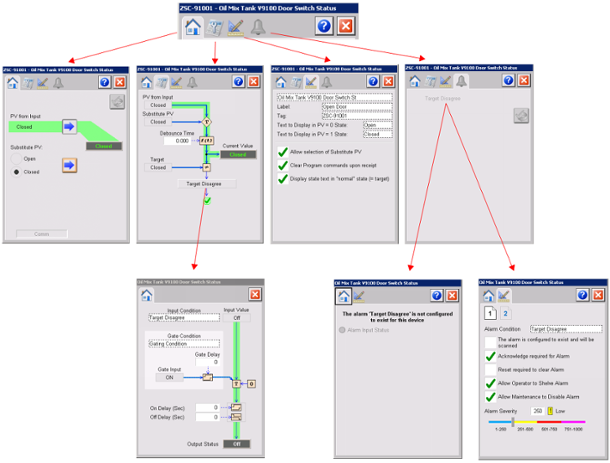

An example of a typical faceplate layout for a P_DIn (Discrete Input) object is shown below.

As shown in the example below, many configuration settings can be changed with a few clicks which gives the user the ability to make changes that would typically be needed to be done using PLC software and by a control’s engineer. The face plates also contain built in security which assures that certain users can only make certain changes to the system is easily achieved.

PlantPAx Programming Considerations Today

While the core principles behind Rockwell Automation’s PlantPAx platform remain consistent, newer implementations place increased emphasis on scalability, cybersecurity, and integration with modern data systems. As manufacturing environments evolve, programming decisions made early in a PlantPAx project can have long-term impacts on system performance and maintainability.

One key consideration is how PlantPAx applications are structured to support future expansion. Using standardized libraries and modular code makes it easier to add units, integrate additional process areas, or support multi-site deployments without rework. This approach also helps reduce long-term engineering effort and simplifies troubleshooting.

Cybersecurity is another growing factor in PlantPAx programming. Network segmentation, user access control, and secure communication between controllers, HMIs, and higher-level systems are now critical design elements. Programming standards should align with plant cybersecurity policies and support secure remote access and patching strategies.

Finally, modern PlantPAx systems are increasingly expected to integrate with SCADA, historian, MES, and analytics platforms. Programming with data accessibility in mind—consistent tag naming, clear structure, and documented logic—makes it easier to connect PlantPAx applications to visualization, reporting, and optimization tools without extensive customization.

Frequently Asked Questions About PlantPAx Programming

What is Rockwell Automation PlantPAx used for?

PlantPAx is a distributed control system platform designed for process manufacturing environments such as chemical, food and beverage, life sciences, and energy. It provides a standardized architecture for control, visualization, and data management using Rockwell Automation technologies.

Is PlantPAx a DCS or a PLC-based system?

PlantPAx is often described as a DCS built on PLC technology. It uses Logix controllers as the core control platform while delivering the standardized structure, libraries, and lifecycle tools typically associated with traditional DCS systems.

When should manufacturers consider using PlantPAx?

PlantPAx is well suited for facilities that require consistent control standards, scalability across multiple process units, and long-term maintainability. It is commonly used when plants want the flexibility of PLC-based control with the structure and repeatability of a DCS.

How does PlantPAx improve programming consistency?

PlantPAx relies on predefined libraries, templates, and naming standards that help engineers develop reusable and consistent code. This reduces custom logic, simplifies troubleshooting, and makes it easier for operations and maintenance teams to support the system over time.

Do you need a certified system integrator to implement PlantPAx?

While certification is not strictly required, working with a PlantPAx-certified system integrator helps ensure the system is designed and programmed according to Rockwell Automation’s recommended standards. This can reduce project risk, improve system reliability, and support long-term success.

PlantPAx offers a powerful framework for building scalable and maintainable process control systems, but its value depends heavily on how it is designed and implemented. Working with experienced engineers who understand both the platform and industry best practices can help ensure long-term success. If you’re planning a new PlantPAx system or updating an existing one, Hallam-ICS can help.

About the Author

Tom Toppin is has left Hallam-ICS to pursue other endeavors, but his contributions to the company continue to be valued.

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina and Texas and our projects take us world-wide.

You May Also Like

These Related Stories

Mr. Whiskers Goes to Rockwell Automation’s Automation Fair

Rockwell Automation’s PlantPAx 5.0 – Understanding the Changes

Comments (6)