The First 2 Steps to Complete your TGMS Safety Requirement Specification

by Dan Maxwell on May 25, 2023 11:14:13 AM

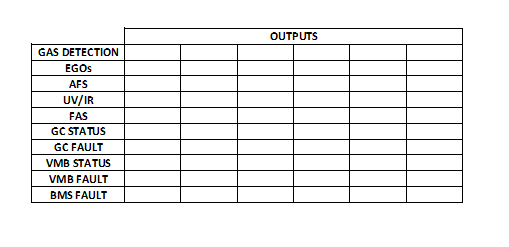

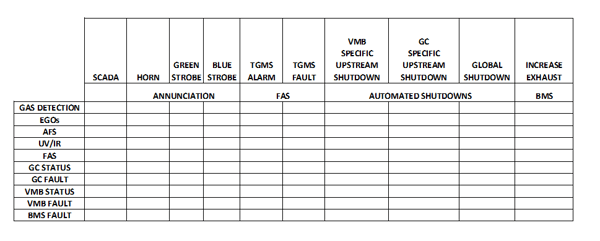

A Safety Requirement Specification (SRS) defines the basic functions of a toxic gas monitoring system (TGMS). It also helps with many design considerations. The format Hallam-ICS prefers to use for documenting is a basic matrix. Spreadsheet tools are an excellent way to manage the SRS.The arrangement of the matrix has Inputs listed in rows and Outputs assigned to column headers. An “X” placed in an individual cell links the input signal to the output action.

Step 1 – Define the Inputs

Inputs to the TGMS can come from a wide range of sources. Gas Detection devices are an obvious starting point. From there, consideration is given to other safety related inputs. These include:

- Emergency Gas Off Buttons (EGO)– For manual global shutdown of all gases. This requires that gas equipment be capable of automatic remote shutdown.

- Air Flow Monitoring – The safe use of many gases requires continuous exhaust. Many pieces of gas distribution equipment have integrated airflow switches (AFS). Loss of airflow causes a gas shutdown. In cases where airflow monitoring is not integrated, the TGMS monitors it. This also requires that gas equipment be capable of automatic remote shutdown.

- Fire Detection devices – When using Silane and other pyrophoric gases, special UV/IR (Ultraviolet/Infrared) flame detection devices are needed. ANSI/CGA G-13 “Storage And Handling Of Silane And Silane Mixtures”, identifies UV/IR and it is best practice to apply the same technology to other pyrophoric gases. It may be desired to have notification of the flame detection directly from the detector or indirectly from the Fire Alarm System.

- Fire Alarm (FAS) – Indication of a fire from the fire alarm system is typically a cause for global shutdown of all gases. Other inputs from the fire alarm system could include individual zone alarms, indication of fire alarm faults, or notification that TGMS audible annunciation should be temporarily silenced for verbal announcements from the FAS.

- Gas Distribution Equipment - Often gas monitoring inputs are sourced from the gas distribution equipment itself. Status and Fault signals from gas cabinets (GC) and valve manifold boxes (VMB) are connected to the TGMS. This is useful information for users and first responders.

- Building Management Systems (BMS) - BMS control the HVAC systems in most buildings. Inputs from BMS are supplied to TGMSs to identify issues such as loss of exhaust or make-up air.

Informational inputs can be wide ranging. Hallam-ICS believes that a TGMS should remain limited to control of gas safety issues. It is easy to feel that with a capable system; more and more controls can be added. However, this tends to bloat the safety system and opens up the possibility of errors by permitting more casual modifications of less critical controls. A TGMS is a validated safety system. Changes should be well documented and tested.

Step 2 – Define the Outputs

Identifying the TGMS outputs starts with deciding what level of user interface is desired. A very basic user interface might just be the lights and horns indicating evacuation. On the other end of the spectrum is a full SCADA (Supervisory Control and Data Acquisition). A SCADA can provide visualization of the status, alarms, and maintenance faults. Historical trends of all gas concentrations values can also presented.

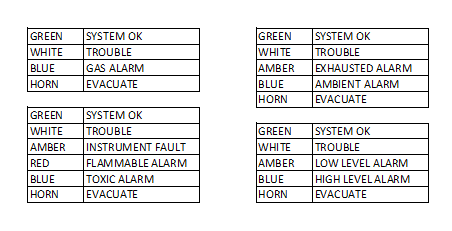

- Annunciation - Annunciation of some form is always required of a TGMS. This is typically done with a combination of visual and audible devices. Some users also utilize visual aids to indicate health of the TGMS, type of alarm event, or high/low alarm.

Examples include:

- FAS - The TGMS will often have outputs to the Fire Alarm System to achieve 24hr. monitoring. Outputs may include a range of alarm and status signals. Determining and coordinating the signals to the FAS is a detailed process and should be well considered and communicated.

- Automated Shutdowns - One of the primary functions of a TGMS is to provide automatic shutdown of gases. Outputs to gas equipment for shutdown should consider the available number of shutdowns and the level of detail of the requested shutdowns. Gas cabinets may have multiple outlets and controllers. It may be determined that there is only one available remote shutdown input for multiple outlets. Likewise, valve manifold boxes (VMB) will have multiple outlets but may or may not have the ability to individually shut down gas sticks. It also may be desired to shut all outlets off regardless of the detail of a specific gas alarm.

- BMS - In some cases, there is a desire to change the operation of an HVAC system during a detected gas release. This action could involve increased exhaust or pressurization changes. An output to BMS permits this to occur.

Next Steps

Once Inputs and Outputs are initially established, the discussion begins with the gas monitoring stakeholders. A logical and consistent approach is critical to set the actions that correspond to the inputs. It may be found that during these discussions additional outputs or inputs are identified. In this way, the SRS is a living document requiring iterative revisions to meet the needs of the project. It is useful to keep accurate records of the revisions of the SRS as well and records of the decision making process.

About the Author

Dan Maxwell is a Senior Project Manager with Hallam-ICS’s Toxic Gas Monitoring team. Dan trained in Mechanical Engineering and has worked in Project Management in the construction and manufacturing sectors before coming to Hallam-ICS in 1999.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina, Texas and Florida and our projects take us world-wide.

You May Also Like

These Related Stories

4 Reasons Your Staff Needs Qualified Electrical Safety Training Today!

The Benefits of Turnkey Engineering Solutions: One Partner from Design to Commissioning

No Comments Yet

Let us know what you think