Does a Toxic Gas Monitoring System (TGMS) Sensor Need a Lockout Tagout System?

by Jeff Champagne on Aug 13, 2020 10:30:00 AM

Currently there are no formal standards of practice for Toxic Gas Monitoring System (TGMS) normal operation deviations.

Purpose

The intended audience for this blog is laboratories, manufacturing, and institutions that operate a continuous TGMS in compliance with OSHA. This blog will try to bring awareness to situations that may require a management of change (MOC) to standard operating procedures (SOP) of a toxic gas monitoring system (TGMS), including a lockout/tagout (LOTO) system. When done properly before equipment service or maintenance, LOTO procedures control hazardous energy and protect workers from harm. The blog will also describe how selecting a TGMS service provider such as Hallam-ICS can help bridge the gap to ensure continued safety success for your organization.

Introduction

Does your organization have a TGMS? If you have answered yes then you may be aware of what toxic gases you are normally working around daily, which is great! Your employer or institution has done their part to make sure you are provided with a life safety system to alert you to possible toxic gas leaks or significant changes to the atmosphere due to toxic gas release. There are also likely alarms and/or lights to alert you and others to those changes when a concentration of toxic gas or oxygen depletion is detected and start various safety protocols to ensure personnel evacuation and alert first responders to the situation.

But what about the cases where grey areas exist? What about when there is a true leak, but you have inhibited a gas detection sensor to change a gas bottles or bunkering gas from a supplier? Under normal operation, the TGMS would alert you to these changes and most facilities have protocols in place that when changing gas bottles or a gas on loading to their facility, they require the donning of SCBA’s self-contained breathing apparatus to ensure safety during these operations and a means of portable toxic gas detection. But why would you inhibit the toxic gas detection sensor? A popular reason is to not cause a system alarm, which could start a panic, building evacuation, and or alert the fire department & EMS.

Discussion

When thinking of a LOTO system, the first thing that comes to mind is the system which electricians and technicians tagout electrical breakers or equipment to work on it safely. I use this example because like electricity, toxic gas cannot be seen and can be equally hazardous and fatal if not given the respect that is due.

So why might you need a LOTO system for a gas detection sensor?

- The TGMS being operated outside of standard operating standards. (i.e. sensor in inhibit, alarms or alert lights disabled)

- Ensuring compliance with organizational MOC’s

- Having an administrative control to ensure accountability for placing the TGMS back into a normal condition.

- To ensure the sensor is placed back in service in a timely manner, in order to detect leaks from possible human error during the operation which it was placed in inhibit.

- Compliance with OSHA workplace safety standards for toxic gas atmospheric monitoring.

Formation of a TGMS Sensor LOTO System

In order to successfully implement a TGMS sensor LOTO system, you will need to get familiar with your organizations administrative and safety procedures to ensure compliance and a smooth integration. The following questions should be a part of your data collection process:

- Does your organization have a formal administrative process?

- Is there a Management of Change (MOC) process in place?

- Has Hazard Analysis and Risk Control (HARC) been completed for each instance in which an MOC is necessary to place a toxic gas sensor/alarm in inhibit?

- In operations that require a TGMS sensor to be inhibited, will there be a portable means of local toxic gas detection?

- Is the area going to be barriered off to ensure personnel not involved are clear from the area?

- What kind of PPE is required for the persons preforming the operation?

- Do you need a safety monitor?

- Does your TGMS have written Standard Operating Procedures (SOP)?

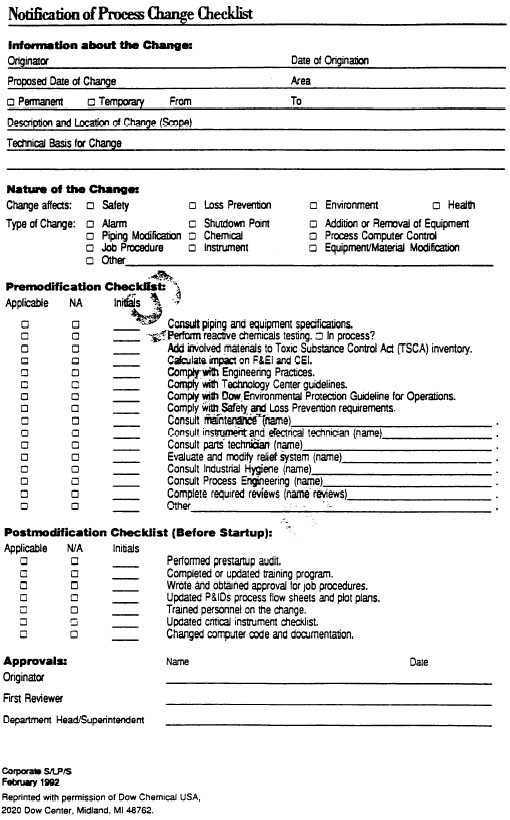

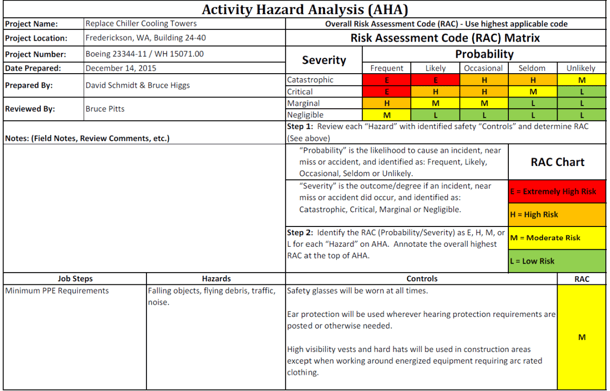

Example of process management of change form

Example of a Job safety analysis (JSA) with a Hazard Analysis Risk Control (HARC)

TGMS Sensor LOTO System

When it comes to any new system involving workplace safety, in my experience ease of use is the main factor in employee participation. How your TGMS operates and is setup will play an important factor into the formation of your LOTO system. In some cases, it may be necessary to consult your TGMS service provider/manufacturer manuals for technical instructions related to your system for sensor/alarm silencing or sensor inhibit procedures. Once you have the technical information you need, you can formulate a written set of procedures for LOTO of one or more sensors or sensor alarms depending on what the operation calls for. By this point you should have a Management of Change (MOC) and Hazard Analysis and Risk Control (HARC) completed and approved.

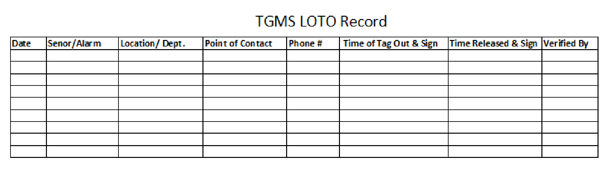

The simplest way to accomplish this is to use a logbook or excel sheet with a format which works for your need and level of accountability required.

Example of TGMS simple LOTO log

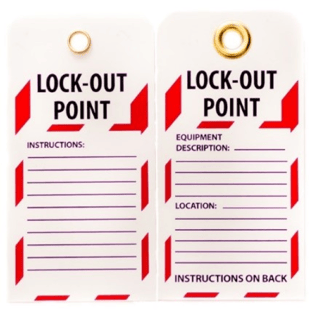

The next consideration should be something at the control panel for your TGMS. Some monitoring systems will have a status screen which can be customized to display when an alarm or sensor is disabled or inhibited, which should be enough along with a sign displaying a caution and or warning in the locations affected by the operation taking place. However, if the TGMS doesn’t support a displayed status of disabled sensors or alarms, it’s recommended a paper caution or danger tag be affixed to the control panel labeled with the sensor or alarm being disabled or inhibited along with proper signage at the location affected. Below are some simple examples that may help:

Example of LOTO paper TAG

Example of area warning or caution signage

Conclusion

No matter the size, type, or manufacturer of a TGMS, there is a way to ensure safety and health standard practices are implemented. If you have any concerns or questions about the safety, integrity, and administrative controls of your TGMS please contact us at Hallam-ICS for a consultation and we can work with you to accomplish your company or organizations desired goals.

Advantages a Hallam-ICS TGMS Can Bring

- Over 20 years of experience with Toxic Gas Monitoring and Controls. To include system development, installation, code compliance, commissioning & start-up, and service & maintenance.

- Completely customizable TGMS human user interface (HMI) software, with administrative controls such as daily TGMS operational reports, alarm, sensor, and maintenance status notification alerts via HMI and E-mail. Which keeps the owner informed of any system status changes for everyday peace of mind.

- TGMS training and solutions. From training your organization on your new system to helping solve administration controls to ensure the continued safety of your organization.

- Devoted to continuous improvement through best practices and our commitment to client success.

References

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1450

https://www.hallam-ics.com/toxic-gas-monitoring-systems-tgms

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.147

About the Author

Jeff is a Senior Instrumentation & Controls Technician Supervisor from Louisiana with 20 years’ experience. From humble beginnings while serving in the U.S. Naval Submarine force, to honing his technical skills in the offshore oil drilling industry while refining cutting edge prototype equipment. Areas of expertise include safety, training, electrical, electronics, mechanics, root cause failure analysis troubleshooting, maintenance, technical writing, and training development.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

The 3 Top issues when upgrading your LON-based Toxic Gas Monitoring System (TGMS)

Toxic Gas Monitoring System Service and Maintenance Plan- Part 2

No Comments Yet

Let us know what you think