Linking Emerson Level Sensors to Ignition Dashboards for Real-Time Tank Insights

by Elizabeth Engler on Jan 29, 2026 10:30:00 AM

A manufacturing plant faced ongoing challenges managing waste product from a brine injection process. These included spending more on dump visits when there was little product in the tank or risking overflow when not dumping often enough, and the composition of tank material varying wildly which can push the limits set by the waste treatment plant and incur fines.The plant had been relying on manual readings from a plum bob gauge but could be very inaccurate due to layer separation of the tank contents and checks were not always made regularly.

After installing a reliable level transmitter for the collection tank, they can more effectively manage usage habits and activities, align fill and drainage cycles to be more efficient, and get accurate real-time measurement despite material layer separation in the tank.

Why Material Composition Matters

The composition of material in the tank must be maintained within limits set by the waste treatment plant for ratios of water, salt, sugar, fats, and chemicals and could be fined if certain percentages are too high. However, if the media is too diluted with water, the plant wastes money disposing of more watered-down material when they could have kept the volume lower.

By tracking tank level history, level trends can be compared to known process activities happening at the same times and managers can infer the resulting material composition in the tank. These insights now guide more cost-effective drainage scheduling and process adjustments.

A Persistent Challenge: Layered Tank Contents

The tank contains a mixture of water, salt, sugar, fats, and chemicals, some of which rise to the top and solidify into a thick sticky crust. When the liquid level below drops, the crust remains on top with an air gap between.

The previous plum bob gauge would get stuck on the top layer and give the false impression the tank was full. To get even a remotely accurate measurement, for each visual inspection, one would need to climb up and use a tool to punch through the top layer and feed the bob through, a time-consuming and unpleasant process you can imagine. Even then, the bob could be getting stuck on lower layers and reading inaccurately.

This process was:

- Time-consuming

- Unpleasant and unsafe

- Often skipped, leading to poor data

- Unable to detect actual level beneath the solid top layer

The result: inefficient drainage scheduling, unpredictable dump volumes, and unnecessary disposal costs.

A Guided Wave Radar Solution: Emerson Rosemount 5301

Like a multi-layer cake, the Emerson Guided Wave Radar (GWR) sensor identifies each layer with precision. The plant selected the Rosemount 5301 Level Transmitter with a rigid probe, which excels at detecting:

- Liquid level beneath solids or crusts

- Interfaces between unmixing materials

- Ullage (empty space)

The transmitter’s accuracy (down to 1 inch) and reliability make it ideal for tanks with complex media like brine, sugar, fats, and chemical mixtures.

Key Features That Made the Difference

- Advanced signal processing for challenging tank conditions

- Dynamic vapor compensation

- Direct switch technology produces stronger, cleaner radar signals

- Probe-end projection to reduce noise

- Corrosion resistance and no moving parts

- No routine calibration required

Installation is straightforward, and Emerson’s local support technician provided on-site setup and configuration free of charge

Connecting the Sensor to the Plant Network

The sensor supports HART or Modbus; this application uses Modbus RTU RS-485, converted to Modbus TCP using a RS485-to-Ethernet converter. This allows live measurement data to be transmitted across the plant network and pulled into Ignition for visualization.

Similar considerations apply across other measurement technologies. For example, when working with Emerson ultrasonic flow meters, proper installation and data handling are just as critical to ensuring reliable insights downstream.

Ignition: Real-Time Data Anywhere, Anytime

Ignition provides the central hub for displaying tank insights in user-friendly dashboards accessible from any connected device, onsite or remote.

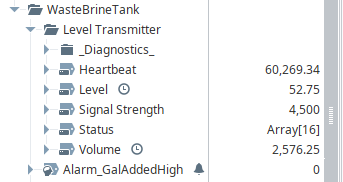

Data Tags Collected from the Transmitter

- Level

- Volume

- Heartbeat

- Signal Strength

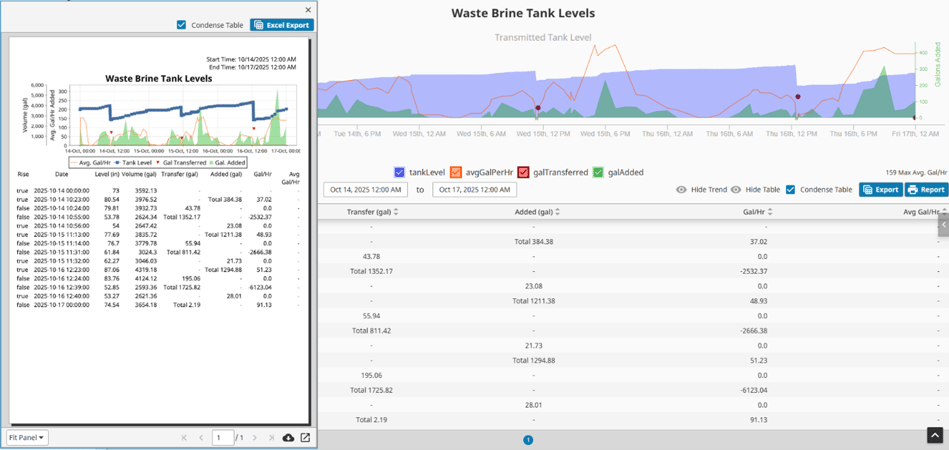

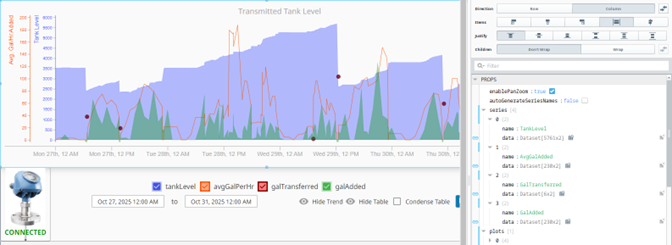

Ignition’s intuitive drag-and-drop interface and powerful design tools make custom dashboard design fast, easy and effective. We use charts, tables, indicators, and reports to display data in multiple digestible formats.

Historical Data Tracking with Tag Historian

Ignition’s Tag Historian enables automatic storage of tag values over time or based on value changes. We configured tag history for Level and Volume, which we use in trends to analyze tank fill patterns.

Charts in Ignition are highly customizable. Using the Tag History data from Level and Volume along with some custom scripts, we have separated out the events and activities that plant managers want to track including:

- Overall tank level

- Average hourly fill rate

- Gallons added each time the level rises

- Drainage events

This data supports:

- Worker accountability

- Process optimization

- Policy verification

- Cost-saving drainage strategies

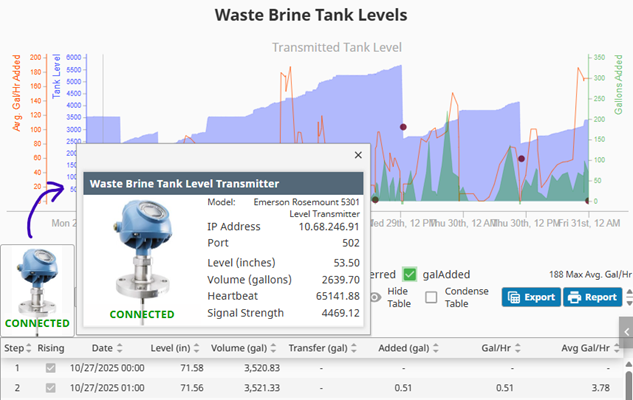

Device Faceplate and System Visibility

A custom Ignition popup displays:

- Device information

- Network status

- Live readings

- Connection details

This gives maintenance teams quick diagnostic insight without climbing a tank ladder or switching software tools.

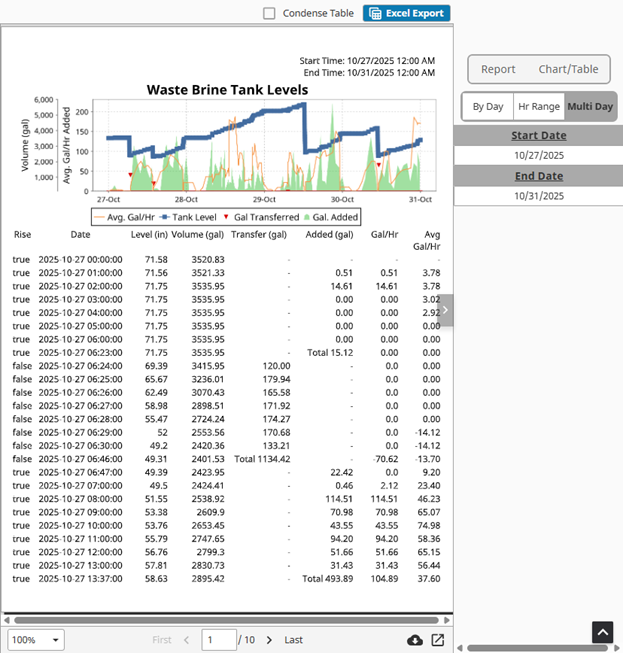

Reporting: Delivering Insights Beyond the Plant Floor

Ignition’s Reporting allows stakeholders to receive key tank insights via:

- Downloadable PDFs

- Automated report emails

- Event-triggered dispatch (e.g., high tank levels)

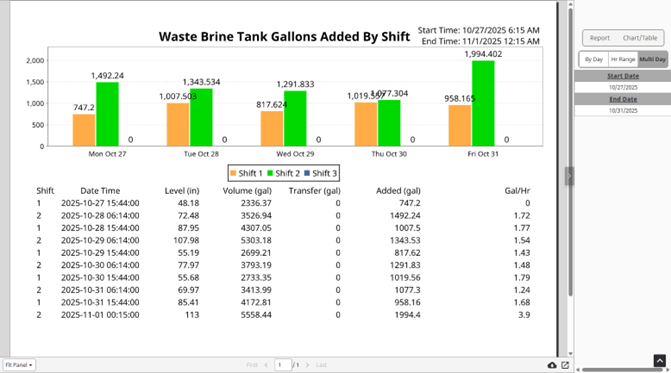

Two key report types were developed:

- Detailed Tank Status Report

Includes hourly data, change markers, and rising vs. falling level segmentation, with both condensed and full-table views.

- Shift-Based Gallon Totals

Shows how much material each shift contributes to the tank, enabling operational benchmarking.

Results: Optimized Tank Usage and Measurable Savings

By integrating Emerson Guided Wave Radar with Ignition’s dashboards, trends, and reports, the plant now has:

- Accurate real-time level readings despite complex tank layering

- Validated historical trends for drainage optimization

- Better control of material composition

- Reduced waste disposal costs

- Clear accountability and operational insights

This project demonstrates how reliable instrumentation + powerful visualization tools can transform a previously manual, error-prone process into a data-driven workflow.

At Hallam-ICS we strive to address each of our customers’ needs, provide the most trustworthy solution, and support their end goals in a reliable, safe, and accurate way. Ask us how we could address challenges at your facility and provide cost and time savings for your team!

About the author

Elizabeth Engler is a Controls Integrator with diverse experience across controls design, programming, and software development. She enjoys logical challenges, user interface design, and programming machines to bring customer's visions to life. In her free time, Elizabeth enjoys gardening, mysteries, movies, and time with family.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina and Texas and our projects take us world-wide.

You May Also Like

These Related Stories

Can Commissioning Be Leveraged Into The Qualification Process?

Ensure Data Integrity in cGMP: The Crucial Role of Validation Processes

No Comments Yet

Let us know what you think