When to Go “Big” with Your Toxic Gas Monitoring System (TGMS)

by Jake Goldberg on Jan 8, 2026 10:30:01 AM

At Hallam-ICS, our Toxic Gas Monitoring System (TGMS) team designs scalable systems for critical facilities, keeping everyone informed and protected.

Of course, not everyone needs a large-scale solution to keep their people and facility safe. Sometimes all a space needs are one or two monitoring points to provide adequate protection.

.

Central TGMS Controllers

When it comes to investing in toxic gas monitoring, there are four questions you should ask yourself and your engineering team:

1. What Gases are You Using?

Generally speaking, the more dangerous the gas, the more complex or “bigger” you should go with your gas monitoring system.

This comes into play for both gas type and quantity. Chapter 5 of the NFPA Hazardous Materials Code (NFPA 400) defines the maximum allowable quantity (MAQ) allowed of different classifications of hazardous materials within a defined control area, including gases classified as the following:

- Flammable

- Inert

- Oxidizing

- Pyrophoric

- Unstable (reactive)

- Corrosive

- Toxic

- Highly toxic

An MAQ analysis will tell you whether the gases in your space exceed what is allowed without additional safeguards. If this is exceeded, a TGMS system can potentially increase the MAQ and bring your space back into compliance.

Learn more about code requirements in our blog: Spill Control & Secondary Containment: Code Basics and Solutions.

Once the team decides that a TGMS system is needed, a greater number of different gases warrants a more expansive system. Certain sensors can detect for multiple gases: LEL sensors can detect combustible gases like methane, hydrogen, and acetylene, and O2 sensors can monitor oxygen depletion from inert gases like nitrogen and argon.

Most sensors are highly specialized to a small range of gas chemistries, in that they may be engineered to react to a limited number of gases in a family. Therefore, a lab space that uses more than a few distinct gases will need multiple sensors. This can warrant adding a central controller that talks to all the sensors, sets off alarms and reports data as necessary.

This bank of ambient detectors is monitoring for multiple gases in a remote location. Multiple sensors would benefit from being hooked up to a central controller.

2. Where Will You be Monitoring?

This question comes down to not just the type of facility to be monitored, but how many individual spaces are up for consideration. The more expansive the target area is, the more likely you’ll need a centralized TGMS controller rather than just individual devices.

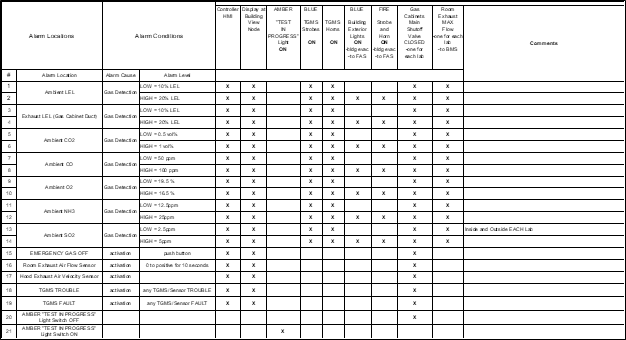

Our TGMS designs include a safety response specification (SRS) which outlines how the gas monitoring system reacts to different alarms and inputs and interacts with other building systems. Below is an example of a typical SRS:

This SRS accounts for dozens of input and output types for a large system.

This example is for a system that monitors over twenty labs and over 250 individual sensors – a centralized TGMS system is necessary in this case. However, individual spaces with minimal gas activity do not need such a large solution.

Examples include a single lab with a handful of inert gas drops, or a corridor that stores liquid nitrogen dewars. These spaces are low risk and self-contained, so standalone devices can save time and money while adequately protecting the area.

3. Who Needs Alerts, and When?

It goes without saying that people within the monitored space need to be notified of gas emergencies, but what about others outside that space? Each facility has its own protocols for all gas alarms, but streamlining the process can be helpful, especially in larger facilities.

Inside a space, the simplest method for notification is a horn/strobe device, similar to but must be distinct from the building fire alarm system’s devices. Outside of the immediate space, additional horn/strobes or strobe-only devices can not only call out a gas emergency in the space, but also evacuate the entire building if it’s severe enough. The latter requires a building-wide TGMS system that can alarm in multiple zones.

For a centralized signal, section 6004.2.2.10.1 of the International Fire Code (IFC) states that the TGMS is required to both initiate a local alarm and transmit a signal to a central, constantly attended control room, when more than one cylinder of highly toxic gas is present. This required signal is done through a central TGMS controller. In addition, a signal to a building management system (BMS) is also viable for large, modern buildings. While some sensors can do this on their own, a TGMS controller streamlines installation and lessens the load on the BMS.

4. How Much is at Stake?

While this last topic seems broad at first, it can offer perspective beyond what the code or the authority having jurisdiction requires. While protecting occupants is the obvious and most critical reason to install one, consider the following for your application:

- Does a gas leak pose a risk to the physical property and building?

- Would unwanted gas buildup affect your labs’ experiments?

- Could early gas detection minimize production downtime?

- Would having a TGMS system give additional financial and functional benefits?

In essence, the more of these questions get a “yes” answer, the bigger you should go with your toxic gas monitoring system.

A properly designed TGMS system will not only protect people and property, but will also last long and adapt to the changing needs of your facility – as your operation grows, so should the systems that protect and run it.

Why “Going Big” With TGMS Can Pay Off

Whether you’re managing a single lab or a campus-wide facility, your gas monitoring system should scale with your risk and operations. A properly designed TGMS ensures compliance, protects personnel, and minimizes costly downtime.

At Hallam-ICS, we design and build monitoring systems that grow with your facility’s needs, from turnkey devices to fully integrated, code-compliant networks.

Frequently Asked Questions:

Q: What does a toxic gas monitoring system do?

A: It detects and alerts personnel to hazardous gas concentrations, helping maintain compliance with NFPA and IFC standards.

Q: When do I need a centralized TGMS controller?

A: When multiple gases, labs, or building zones are monitored, a central controller ensures coordinated alarms and data reporting.

👉 Contact our team to discuss your toxic gas monitoring requirements or request a system assessment.

About the Author

Jake Goldberg is an Electrical Engineer based in Hallam-ICS’s Mansfield, MA office. A graduate of Wentworth Institute of Technology, Jake designs robust electrical and toxic gas monitoring (TGMS) systems for clients across life sciences, higher education, and industrial sectors.

Read My Hallam Story

About Hallam-ICS

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont, North Carolina, and Texas and our projects take us world-wide.

You May Also Like

These Related Stories

How to Develop a Budget for Arc Flash Compliance

Advancing Automation Technology - Layer 3 Core Switch Requirements

No Comments Yet

Let us know what you think