ARC FLASH & ELECTRICAL SAFETY

MINIMIZE ELECTRICAL HAZARD RISK AND ENSURE WORKERS SAFETY

Single building, campus-wide, nationwide or international, Hallam-ICS can provide arc flash studies, offer mitigation solutions and NFPA 70E training for your facility. We can help you with better electrical system performance as a result of coordination studies for low & medium voltage systems. Your employees will benefit from improved safety with labelling, selecting proper level of PPE and electrical safety training.

ARC FLASH & ELECTRICAL SAFETY SERVICES

Hallam-ICS offers a variety of engineering services to owners, architects, and construction managers who are developing clean, dirty, and dangerous systems. Our comprehensive understanding of high-level business goals and deep technical knowledge will turn your facility into a competitive advantage for your organization.

ARC FLASH ASSESSMENTS

ARC FLASH ASSESSMENTS

INFRARED THERMOGRAPHY

INFRARED THERMOGRAPHY

ELECTRICAL SAFETY PROGRAM COMPLIANCE

ELECTRICAL SAFETY PROGRAM COMPLIANCE

QUALIFIED ELECTRICAL SAFETY TRAINING

QUALIFIED ELECTRICAL SAFETY TRAINING

ARC FLASH ASSESSMENTS

When it comes to electrical safety, the risks associated with complacency are too great to ignore. We perform detailed arc flash assessments and 5-Year Updates to implement and uphold cost-effective solutions for arc flash mitigation.

Our process engineering services include:

- Field Surveys & Data Collection

- One-Line Development & Updates

- Engineered Arc Flash Analysis

- Short Circuit Analysis

- Coordination Studies

- Labeling & Training

- Mitigation Solutions

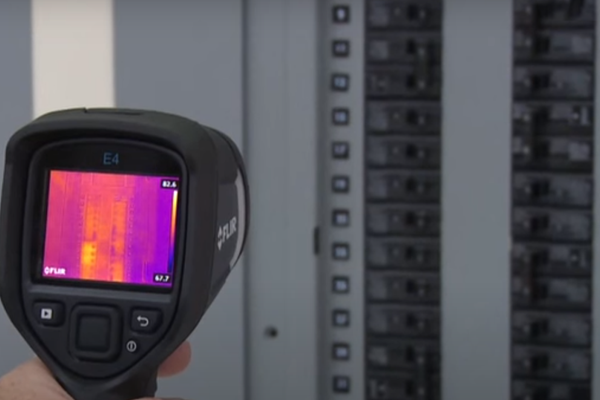

INFRARED THERMOGRAPHY

The number one reason electrical equipment fails is fires involving lighting and power distribution equipment. Using IR thermography on a regular cadence as part of your predictive maintenance program will allow you to identify when it’s time to fix or replace a component.

Our infrared thermography services include:

- IR Thermography

- Systems and Findings Analysis

- Report Generation

- Predictive Maintenance

ELECTRICAL SAFETY PROGRAM COMPLIANCE

An electrical safety program ensures employees are trained in safety practices and comply with NFPA 70E, with expert assistance available for compliance. We offer program reviews and new program development.

Our comprehensive program Learning@Hallam is designed to provide organizations with a leading-edge solution for electrical safety training and compliance. With a focus on continuous improvement and tailored solutions, Learning@Hallam offers:

- A wide range of courses

- Skills Evaluation

- Site Safety Audit

- Data Analysis

- Safety Briefings

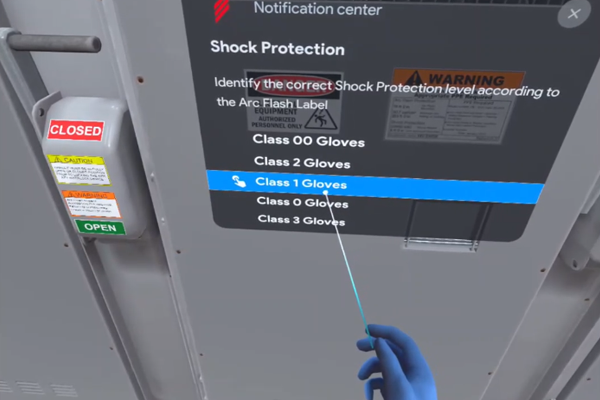

QUALIFIED ELECTRICAL TRAINING

Backed by a team of Electrical Safety Specialists, curriculum developers, and platform managers, our training program offers In-Person, Virtual-Instructor Lead, On-line self paced, and Virtual Reality training, and provides an opportunity for new and tenured employees to meet regulatory requirements and standards. We offer a wide range of training courses, including:

- Electrical Safety Awareness

- Qualified Electrical Worker - Low Voltage

- Qualified Electrical Worker - High Voltage

- Control of Hazardous Energies - Lockout/Tagout

- Human Performance Errors

Our Qualified Electrical Worker Training includes:

- 8-Hr Qualified Electrical Safety Course

- Awareness Training Arc Flash Loss Prevention

- On-Site Training

- 3-Year Retraining Updates

This training is required before an individual can be deemed qualified, i.e. demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations AND has received safety training to identify and avoid the hazards involved.

WHY HALLAM-ICS?

Hands-on Knowledge

We are a team of established subject matter experts for conducting arc flash studies and electrical safety training. All work is performed by our degreed electrical engineers who are trained to properly conduct accurate field surveys and utilize infrared thermography.

Helping you reach compliance and safety goals

Improved safety for personnel from labelling, selecting proper level of PPE and electrical safety training so that your employees can work safely and return home to their families after each and every shift.

Solutions for Any Location

In the last 15 years alone, we have completed over 3,000 arc flash studies in the United States, Canada, and Mexico. And whether it is a single building, campus-wide, nationwide or international locations, we can help.

Extend the life of electrical equipment

Better electrical system performance as a result of coordination studies for low & medium voltage systems reduces the risk to employees and your facility.

RELATED RESOURCES

Explore our library of resources to learn more about our exceptional engineering solutions in a variety of applications.

CASE STUDY

Infrared Thermography Inspection

CASE STUDY

Power System Arc Flash

CASE STUDY

Arc Flash Analysis

CASE STUDY

Short Circuit Coordination & Arc Flash Analysis

SUCCESS WITH HALLAM-ICS

Clients across industries benefit from our engineering expertise, responsiveness, and project management.

Frequently Asked Questions

Common mitigations include verified protective device settings, zone-selective interlocking, differential protection, arc-flash relays, maintenance/test modes, and equipment upgrades that speed clearing. Hallam-ICS provides options prioritized by risk reduction, downtime, and cost.

Incident energy and boundaries are calculated to IEEE 1584-2018, while safe work practices and labeling follow NFPA 70E. Hallam-ICS combines both so engineering results connect to field procedures and PPE.

OSHA requires employers to protect workers from known electrical hazards; NFPA 70E is the nationally recognized standard that provides the methods to comply - safe work practices, risk assessment, PPE, and labeling. Aligning with 70E helps reduce shock/arc-flash injuries, fires, downtime, and citations. Hallam-ICS engineers align studies, labels, and procedures to NFPA 70E and your LOTO/ESWC program.

Yes. We provide site-specific training for qualified workers covers shock/arc flash hazards, boundaries, energized work permits, PPE selection, and reading labels. We can also help align your Electrical Safety Program with OSHA and NFPA 70E.

Hallam-ICS lowers total cost by:

- Updating, not rebuilding your existing SKM/ETAP/EasyPower models, one-lines, and label databases.

- Phasing the work into fixed-price milestones so you fund only what you need (model → calc → mitigation → labeling).

- Right-sizing site hours with client photo/data templates that our engineers validate.

- Bundling scope (short-circuit, coordination, labeling) to cut duplicate visits.

- Prioritizing low-cost mitigations (settings, maintenance mode, ZSI) before recommending hardware.

Data collection and one-line modeling → short-circuit analysis → protective device coordination → IEEE 1584 incident-energy calculations → mitigation recommendations → label creation and field application. Hallam-ICS engineers also provide settings files and a mitigation roadmap (e.g., faster clearing, maintenance modes).

NFPA 70E requires the assessment be reviewed at intervals not to exceed five years and updated whenever major system changes occur (e.g., new gear, transformer swaps, utility feed changes) so labels and PPE remain accurate. Hallam-ICS can monitor changes and refresh labels as needed.

Labels should clearly communicate incident energy (or PPE category), arc flash boundary, working distance, and job-specific PPE/approach details so qualified workers can make safe choices at the equipment. Hallam-ICS produces durable, code-aligned labels and the supporting calculations.

An arc flash study (incident energy analysis) models your electrical distribution to calculate fault currents, protective device clearing times, and incident energy per IEEE 1584, then produces arc flash boundaries, PPE categories, and equipment labels. Typical scope also includes short-circuit and protective device coordination studies so settings reduce hazard and nuisance trips. Hallam-ICS arc flash and electrical safety engineers deliver the end-to-end analysis and labeling.

OUR TAILORED APPROACH

Whether you are a semiconductor manufacturer, life sciences company, or industrial plant, our tailored approach ensures that our solutions are perfectly aligned with your unique requirements and timeline. At Hallam-ICS, our approach is rooted in a culture that values collaboration, meticulous attention to detail, and an unwavering commitment to safety. Our team’s engineering expertise and ability to tailor our services to different industries and needs sets us apart, making us a trusted partner in achieving your operational goals.

We follow our proprietary CODES™ process—COMMUNICATIONS, OVERSIGHT, DOCUMENTATION, EXPECTATIONS, and SCHEDULE—to deliver exceptional project quality and consistency. Each project starts with a comprehensive discovery phase, when we gather critical information about your needs and milestones to develop a customized project plan that ensures seamless execution. Throughout the project, we maintain open lines of communication and provide detailed documentation, ensuring that every phase is meticulously managed. Our commitment to technical excellence, combined with our robust customer service, guarantees a successful project outcome and an exceptional customer experience.

FROM OUR BLOG

Stay updated with the latest insights, trends, and expert engineering advice on our blog.

What Is an Arc Flash Study? NFPA 70E Requirements Explained

The Hidden Risks of Untrained Infrared Thermography