Advancing Automation Technology - How to Specify a vCenter Server

by Jamie Godbout on Oct 6, 2016 1:07:42 PM

Advancing Automation Technology series will take an in-depth look into how the latest technology is being used to develop state-of-the-art control systems. We will select various software and hardware packages being used today, and provide you with the best practice techniques on how to apply them, and when you should consider applying each topic.

- Advancing Automation Technology With FactoryTalk® Batch - How is a FactoryTalk® Batch solution different from a traditional PLC project?

- Advancing Automation Technology - Part 1: Server Hardware Requirements

- Advancing Automation Technology - Server Rack Requirements

- Advancing Automation Technology - Layer 3 Core Switch Requirements

- Advancing Automation Technology - How to Specify a Domain Controller

- Advancing Automation Technology - How to Specify a Hypervisor

- Advancing Automation Technology - How to Specify a vCenter Server

- Advancing Automation Technology - How to Specify Shared Storage

- Advancing Automation Technology - How to Specify a KVM Console

- Advancing Automation Technology - How to Specify a UPS

How to Specify a vCenter Server

How to Specify a vCenter Server

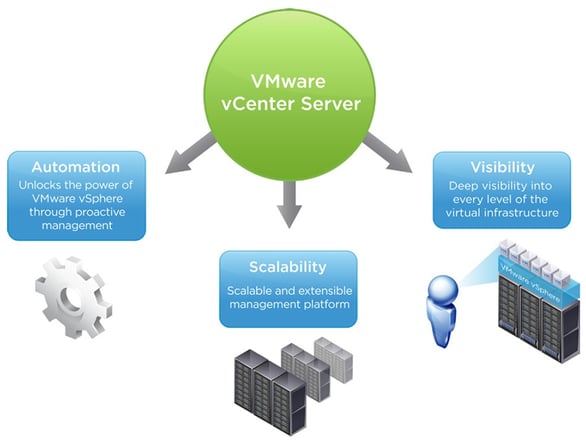

When you decide you are going to virtualize a system you are going to need some way to manage it. VMware uses a software application called vCenter that will connect to all of the hypervisors on your system and provide you with the tools to manage your virtualized platform. The most common tools you will use include: creating virtual machines, creating and deploying templates, migrating virtual machines, manipulating files in the storage area (called a datastore), deleting virtual machines, configuring virtual networks, and monitoring system performance.

Hardware Requirements

The computer you will need to function as a vCenter server in your FactoryTalk Batch control system does not need to be very powerful. You can choose to use a vCenter virtual appliance provided for free from VMWare, but you will need to balance convenience over cost. The virtual machine is a Linux based appliance that will live on your host. Typically, a virtualized control system will not require very many hypervisors so your appliance will be running on the primary hypervisor. You will run into difficulties when having to start or stop the hypervisor because you normally would do that with vCenter, but you can’t necessarily start up the hypervisor from vCenter if vCenter isn’t running because the hypervisor is powered down. So in this case you would need to use vSphere (the client used to communicate with vCenter) and connect directly to the hypervisor to power up, and start vCenter. Then, after everything is up and running you can reconnect to vCenter and manage the system as you normally would.

If you do decide to virtualize the vCenter machine, the deployment system for the appliance will automatically size the virtual machine for you based on how many hypervisors you intend to create and this section will not apply to you. This blog will describe the hardware requirement of a server where vCenter will be installed.

Everybody has a particular preference on server brand, my preference is Dell PowerEdge R620 servers. There isn’t any specific reason for this other then I happened to have started using Dell servers, and it stuck. You can use Cisco, HP, IBM, whatever your personal preference is or if you your company has a standard type of server it would be a good idea to stay consistent. The engine running under the hood is the important thing.

The vCenter server can be a base level server and doesn’t need a lot of bells and whistles. So try to save some money here and save the extras for the virtual system host(s). The important requirements are going to include:

- 19” Rack Mount Server

- Rack Mounting Slide Rails

- Cable Management Arm

- Dual Core Processor (no need to upgrade the CPU, the default processor should be fine)

- 4 GB of RAM

- At least 80GB of storage (Hard drives)

- Go for the hardware RAID controllers, don’t depend on software RAID

- With the vCenter server, I would go with RAID 1 (mirrored drives) so you only need 2 drives, in the unfortunate event one fails

- At least 1 gigabit Ethernet port, most will come with at least two ports

- CD or DVD drive

- Redundant power supplies (make sure the power supplies are big enough for the selected hardware, Dell will show a warning if this is a problem)

Software Requirements

To create the vCenter server you will need an operating system and VMWare vCenter. The most common OS, and in fact the only one that I use is Microsoft Windows Server. You will have to check with the compatibility on the control system, but for the vCenter server Windows Server 2012 R2 will be the OS of choice in almost all situations.

You will need to purchase vSphere Essentials at a minimum. vSphere comes with many different levels and price points. For a basic system, where you do not require high availability or fault tolerance, and will have 3 or fewer hypervisors, then vSphere Essentials will be sufficient. Essentials runs for about $570 with the support contract.

If you do require high availability, fault tolerance and vMotion then you would need to invest in the Essentials Plus Kit. The Essentials Plus kit costs are closer to $5,500, but will get you all the extra features available with vCenter. For most control systems you will not require more than 3 hypervisors, which make the Essentials kits very attractive. The downside about the Essentials kit is that if your system is going to require more than 3 hosts (hypervisors) then you cannot easily upgrade to a larger platform. You would need to go to Standard edition which is significantly more expensive, but becomes more competitive when you have a larger number of hypervisors.

Summary

The vCenter server is going to be the system that allows you to manage your virtual environment. You will be able to clone, move, add, and delete virtual machines as necessary. You can also use vCenter to create a virtual network within the hypervisor, which is also especially useful when you decide to segment your controls network.

Opt for a standard 19” rack mount server with the default options and Windows Server 2012 R2 to be the vCenter Server. It will do the job just fine.

Click here to return to Part I of What Do You Need to Implement a FactoryTalk Batch Solution.

Click here to see my previous post discussing difference between a FactoryTalk Batch solution and a traditional PLC project.

If you have any questions concerning your process control system or require some assistance, please feel free to reach out to our Controls and Automation experts through our

About the Author:

Jamie has left Hallam-ICS to pursue other endeavors. If you have questions about this article or other Ignition questions, contact Tom Toppin, Process Controls Engineer.

About Hallam-ICS:

Hallam-ICS is an engineering and automation company that designs MEP systems for facilities and plants, engineers control and automation solutions, and ensures safety and regulatory compliance through arc flash studies, commissioning, and validation. Our offices are located in Massachusetts, Connecticut, New York, Vermont and North Carolina and our projects take us world-wide.

You May Also Like

These Related Stories

Advancing Automation Technology - Server Rack Requirements

What's new in SQL Server Reporting Services 2016?

No Comments Yet

Let us know what you think